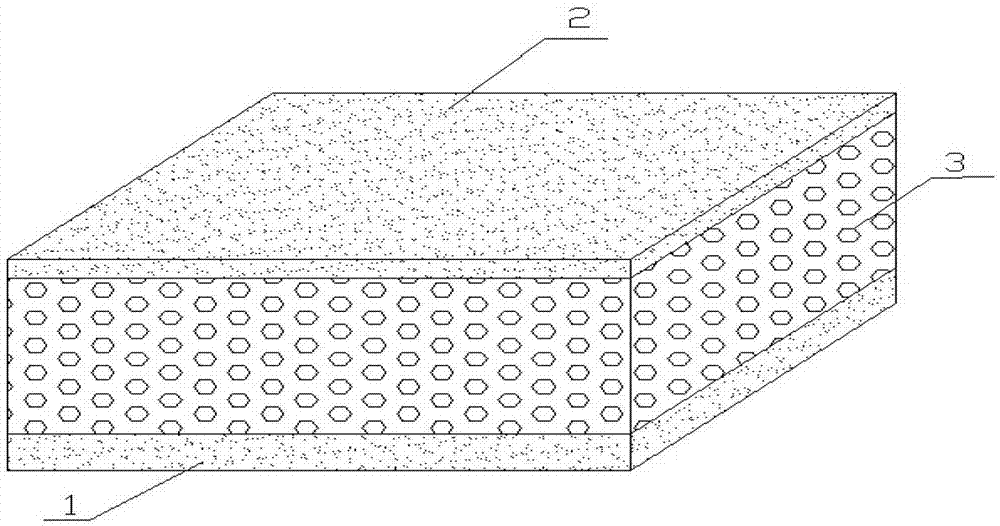

Explosion-proof heat-preservation multifunctional sheet material of foaming concrete sandwich and preparation method of material

A foamed concrete, multi-functional technology, used in thermal insulation, chemical instruments and methods, hydraulic material layered products, etc. , to achieve the effect of simple construction process and strong anti-explosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

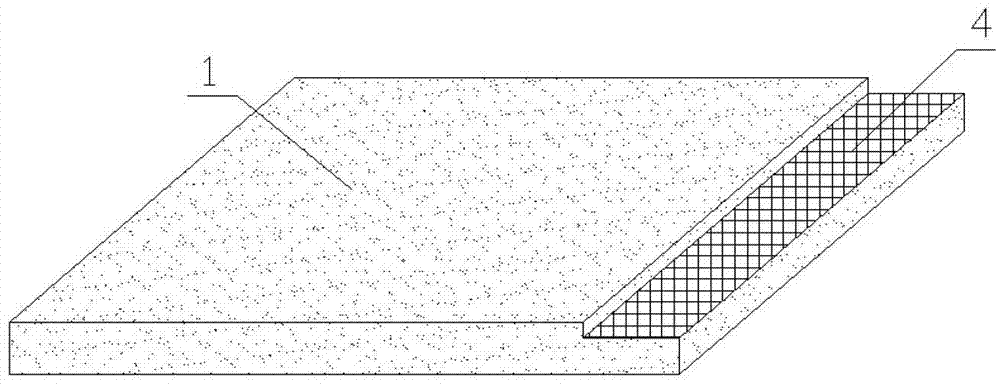

[0049] A Preparation of explosion-proof lightweight mortar outer guard plate:

[0050] 1) 725 high-strength cement and water are mixed according to the mass ratio of 0.4:1, and the total weight is 55 kg. Add it into the mixer and stir for 8 minutes;

[0051] 2) Add 40 kg of lightweight aggregate shale ceramsite, 3 kg of starch ether, and 2 kg of latex powder to the slurry formed in step 1) and stir for 6 minutes;

[0052] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0053] 4) Then carry out moisturizing maintenance according to the traditional process, and finally release the mold;

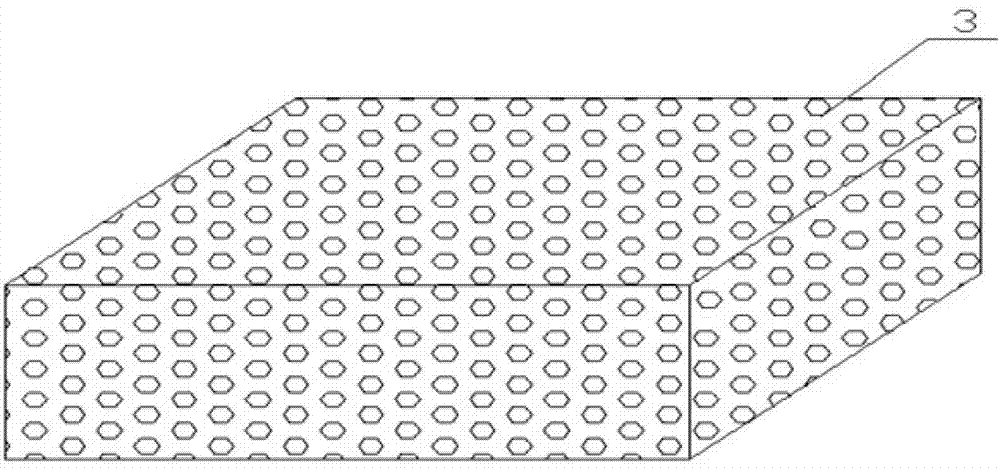

[0054] B preparation of foam concrete core:

[0055] 1) Mix 20 kg of foaming agent hydrogen peroxide, 0.5 kg of VA-01 emulsion or styrene-butadiene emulsion, and 156 kg of water and stir for 2 minutes to make it uniform;

[0056] 2) 50 kilograms of 32.5R Portla...

Embodiment 2

[0060] Explosion-proof lightweight mortar outer guard plate:

[0061] 1) Mix 52.5R sulfoaluminate cement and water according to the mass ratio of 0.5:1, the total weight is 70 kg, add it into the mixer and stir for 5 minutes;

[0062] 2) In the slurry formed in step 1), add 45 kilograms of light aggregate pumice or tuff, polymer modification additive lignocellulose, 2 kilograms of hydroxypropyl methylcellulose (HPMC) or polypropylene fiber, latex powder 3 Kilograms were stirred and stirred for 5 minutes;

[0063] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0064] 4) Then carry out moisturizing maintenance according to the traditional process, and finally release the mold;

[0065] B preparation of foam concrete core:

[0066] 1) Mix 30 kg of LC-2 composite cement foaming agent, 0.3 kg of hydraulic calcium stearate emulsion or vinyl-acrylat...

Embodiment 3

[0071] Explosion-proof lightweight mortar outer guard plate:

[0072] 1) Mix 62.5R slag portland cement and water according to the mass ratio of 0.7:1, and the total weight is 50 kg, add it into the mixer for stirring, and stir for 3 minutes;

[0073] 2) In the slurry formed in step 1), add 25 kilograms of industrial waste light aggregate slag, fly ash ceramsite or natural coal gangue, 4 kilograms of macromolecular modification additive polyvinyl alcohol micropowder, and 1 kilogram of latex powder to stir, Stir for 3 minutes;

[0074] 3) After stirring evenly, pour it into the mold, add a layer of metal grid reinforcement layer when pouring half, and then pour the remaining half, the thickness is about 5-20mm;

[0075] 4) Then carry out moisturizing maintenance according to the traditional process, and finally release the mold;

[0076] B preparation of foam concrete core:

[0077] 1) Mix 12 kg of foaming agent sodium lauryl sulfate (K12), 0.4 kg of VA-01 emulsion, and 216 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com