Construction method for installing underground lattice column

A construction method and lattice column technology are applied in the directions of underwater structures, infrastructure engineering, artificial islands, etc., which can solve the problems of water leakage in the wall and the influence of the construction quality of the underground diaphragm wall, so as to reduce the construction difficulty and reduce the Potential safety hazards and the effect of ensuring construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

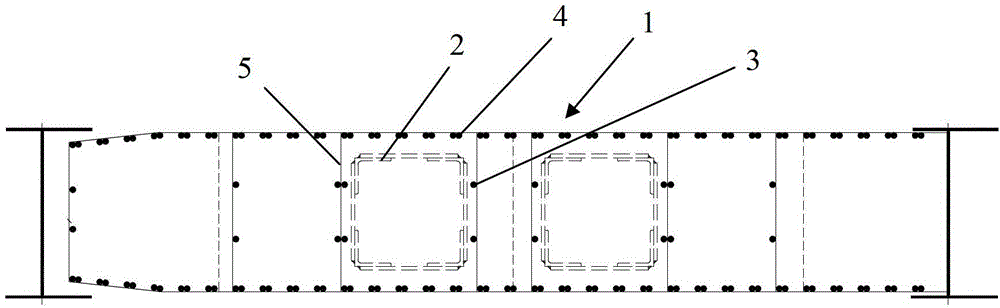

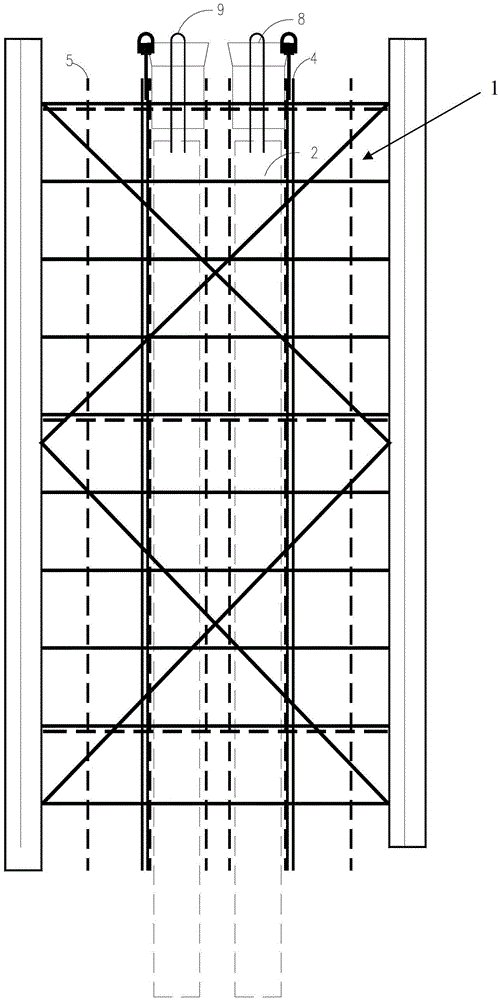

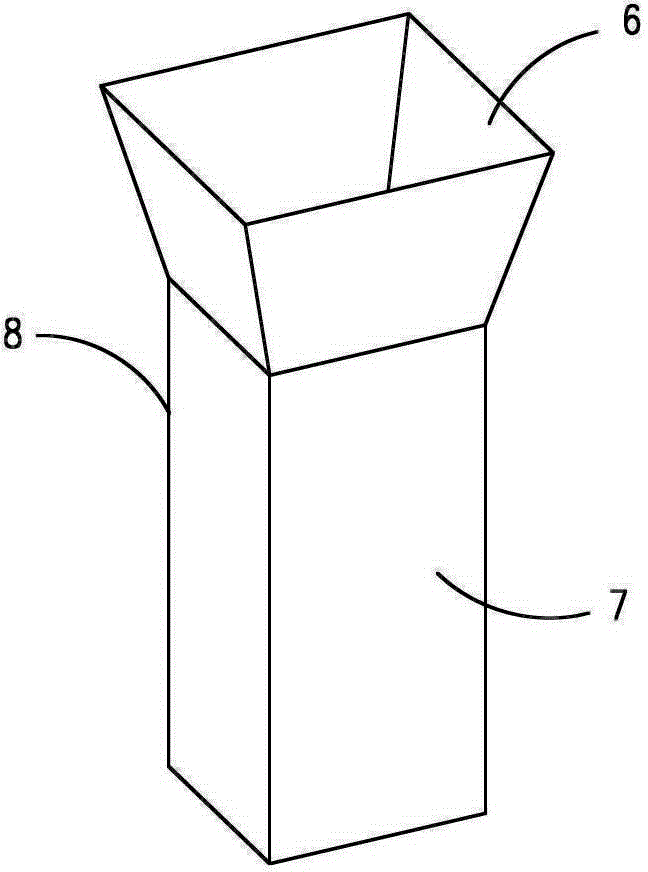

[0019] Insert 2 lattice columns in the steel cage of the underground diaphragm wall as an example to illustrate the specific implementation method of the present invention, please refer to the attached figure 1 , first make the steel cage for the underground diaphragm wall by normal welding according to the design requirements (not shown in the figure), and then erect the auxiliary lifting cage 1 above. The space where the longitudinal truss 5 is about to be inserted and installed with lattice columns is called the enclosed space. A plurality of guide ribs 3 are welded horizontally and symmetrically on the longitudinal truss 5 inside the enclosed space. Lattice columns are planned to be inserted deep into the underground diaphragm wall. The longitudinal truss 5 combined with the guide rib 3 and the main rib 4 enclose to form a guide groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com