Automatic reciprocating type static pressure steel pipe pile machine

A static pressure steel pipe pile, reciprocating technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of narrow construction environment, inaccessible pile driver support, inaccessible cranes, etc., to solve vertical problems. Degree issues, the effect of good verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

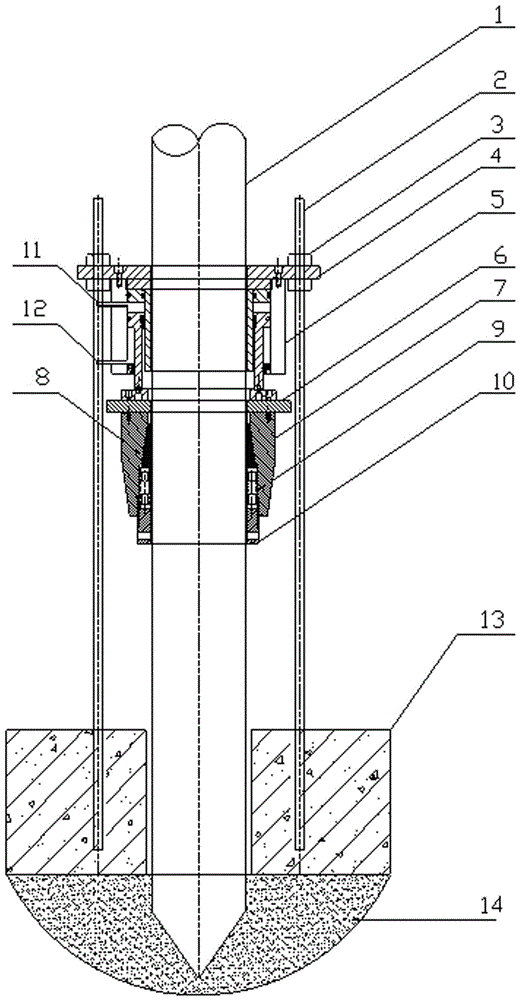

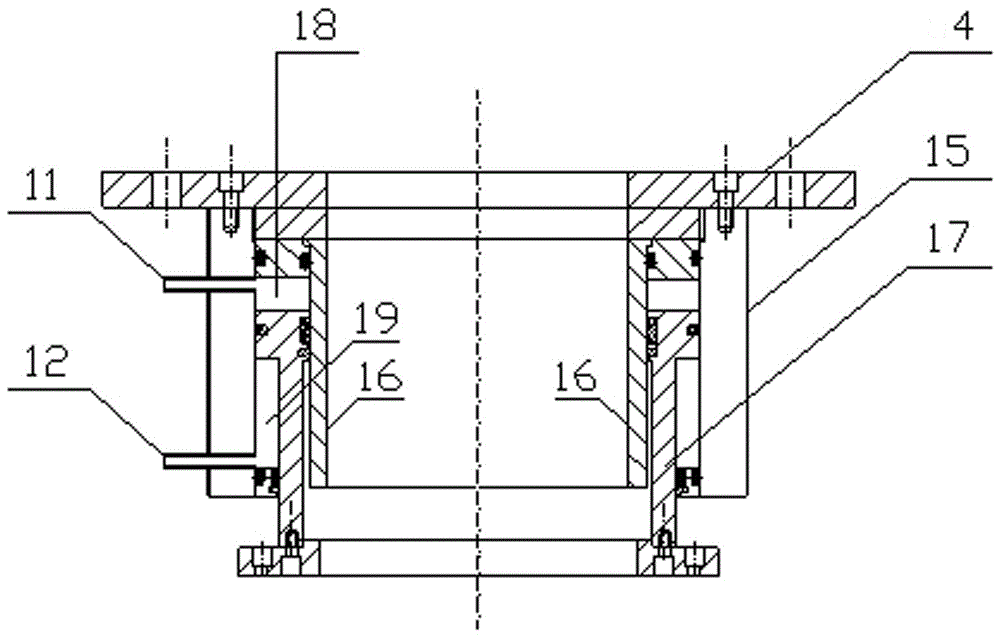

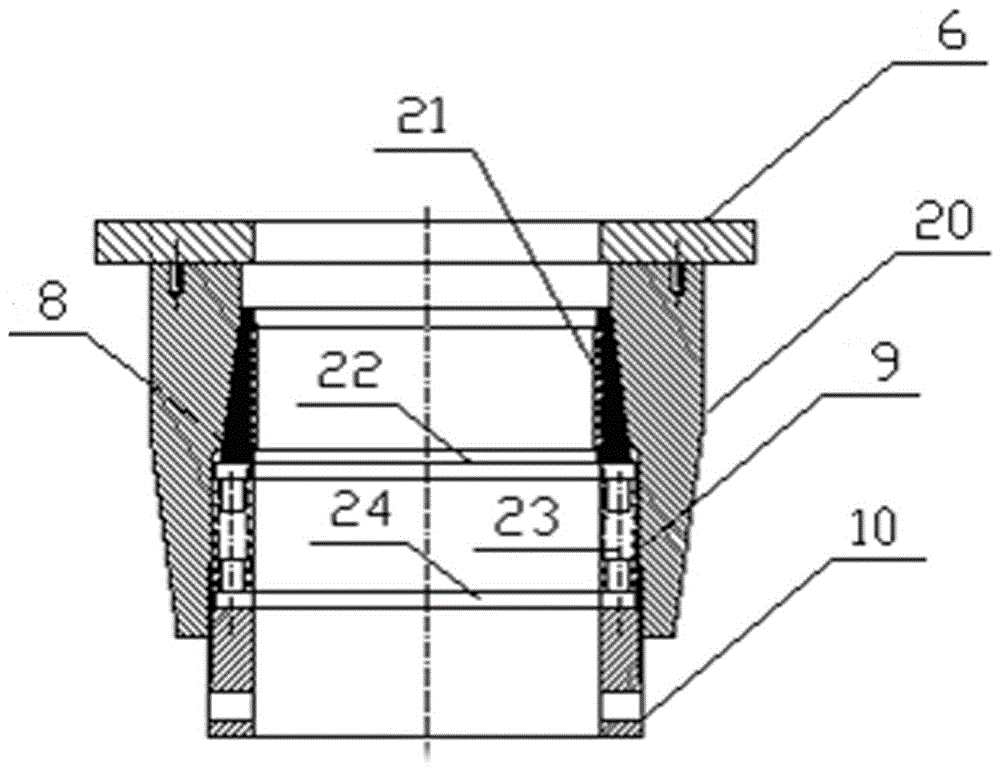

[0026] Such as figure 1 As shown, the automatic reciprocating static pressure steel pipe pile driver of the present invention includes an annular jack 5 for being sleeved on the outer cylindrical surface of the steel pipe pile 1, and the top of the cylinder of the annular jack 5 is fixed with a The upper flange plate 4 connected with the anchor rod 2 is fixed at the bottom of the piston of the ring jack with the lower flange plate 6 for connecting with the annular steel pipe holder 7; the annular steel pipe clamp connected under the lower flange plate 6 The upper section of the inner cavity of the outer steel ring 20 in the holder 7 is a conical annular cavity section, and at least two clips 8 for clamping the tile-shaped structure of the steel pipe pile 1 are arranged in the conical annular cavity section, and The outer surface of the clip 8 is a conical stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com