Aqueous alkyd acrylic resin printing ink and preparation method thereof

A technology of alkyd acrylic and resin ink, applied in the direction of ink, application, coating, etc., can solve the problems of material performance deterioration, etc., and achieve the effects of reduced VOC content, good weather resistance, and good color retention

Inactive Publication Date: 2012-10-24

LANZHOU UNIVERSITY OF TECHNOLOGY

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the resin has poor compatibility due to differences in molecular weight or functional group structure, although it can be uniformly dispersed under the action of a solvent, during the curing and molding process, as the amount of solvent in the system decreases, different types of resins will show phase separation. material performance deterioration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Login to View More

Abstract

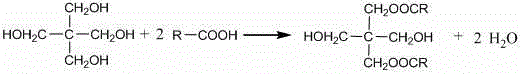

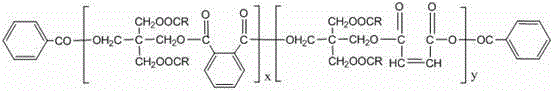

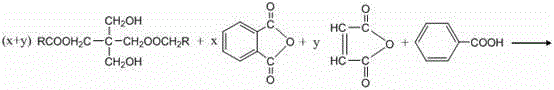

The invention relates to an aqueous alkyd acrylic resin printing ink and a preparation method thereof. According to the invention, high-molecular alkyd resin with main chain containing unsaturated double bond is synthesized through molecular design. Alkyd resin is subjected to free radical graft copolymerization with acrylic monomer. A reaction system is neutralized by using an amine compound, such that water-reducible alkyd acrylic resin is synthesized. Molecular chains of alkyd and acrylic resins are connected through chemical bond, such that the compatibility of the two resins is improved. In a material curing and shaping process, phase separation of the resin is avoided. Deionized water, a pigment, a filling material, an antifoaming agent, a dispersing agent, a siccative, and alkyd acrylic hybrid emulsion are uniformly dispersed, such that the aqueous alkyd acrylic resin printing ink is obtained.

Description

technical field [0001] The invention relates to polymer chemistry and polymer coating composition technology. Background technique [0002] Most of the polymers used in traditional coating inks are solvent-based, and the main varieties are: alkyd resin, acrylic resin, phenolic resin, epoxy resin, polyurethane resin, amino resin and their mutual modification. These resins will use a large amount of organic solvents in the application of late coating inks and in the construction process. These solvents will volatilize into the atmosphere during construction and material curing, which is harmful to the health of construction workers, pollutes the environment, and causes energy waste. With the increasing awareness of environmental protection in various countries around the world, the restrictions on the content of volatile organic compounds (VOC) in inks are becoming increasingly strict in environmental protection regulations, and the ink industry is developing towards low pol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D11/00C09D151/08C09D7/12C08F283/01C08F220/06C08F220/14C08F212/08C08F220/18C08F220/28C08G63/52C08G63/49

Inventor 杨保平吴纯崔锦峰周应萍郭军红李延华李军陈碧碧魏小赟倾彩霞崔卓

Owner LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com