Sludge-based adsorbent used for desulfurization and demercuration of flue-gas and preparation method thereof

An adsorbent and sludge technology, which is applied in the field of sludge-based adsorbent for flue gas desulfurization and mercury removal and its preparation, can solve the problems of adding additives, etc., and achieves improved porosity, simple process, shortened treatment and disposal, and resource utilization. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

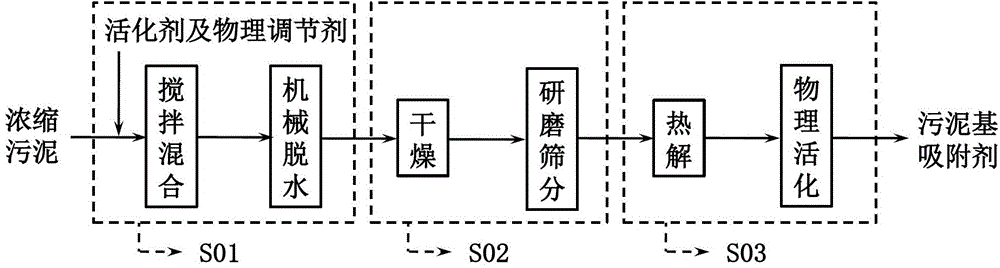

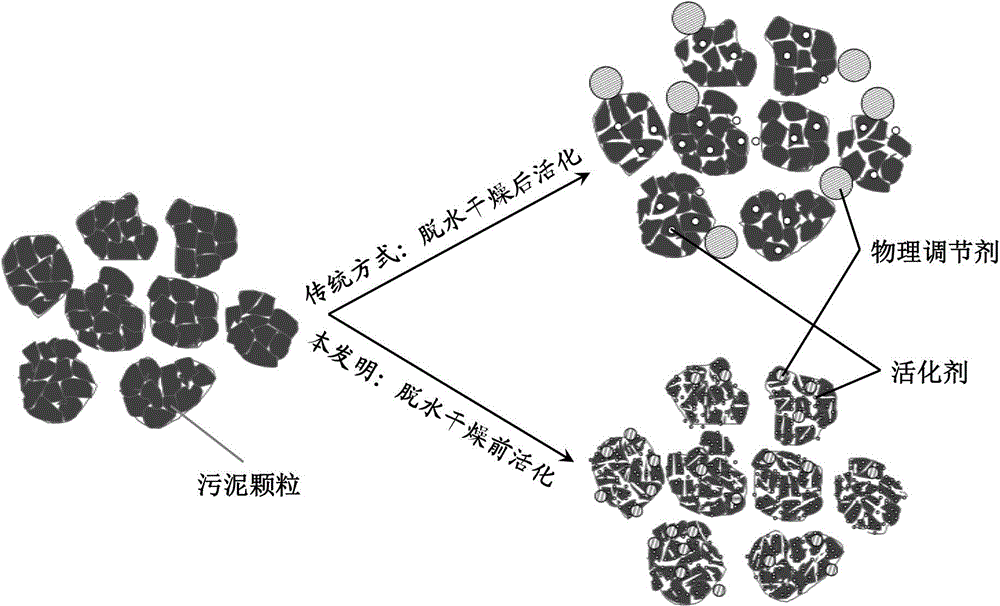

[0037] Step S01: Take municipal sludge with a moisture content of 99.0%, and sequentially add H with a mass fraction of 40% to the sludge slurry 3 PO 4 and H 2 SO 4 As an activator, stir for 15 minutes, the activator is 20% of the dry weight of the sludge; then add Ca(OH) with a mass ratio of 3:1 2 Mix with biomass particles as a physical regulator, stir for 5 minutes, and the physical regulator is 50% of the dry weight of the sludge; after mixing, use a plate and frame filter press to dehydrate.

[0038] Step S02: Dry the activated sludge under air at room temperature for several hours, then grind and sieve to obtain sludge with a particle size of 0.1-2mm.

[0039] Step S03: at N 2 Under the atmosphere, the sieved sludge was heated to 500 °C at a heating rate of 15 °C / min and kept for 90 min for pyrolysis, and then activated by steam for 30 min. 2 The sludge-based adsorbent is prepared by cooling to room temperature in a protected state.

[0040] The BET specific surfac...

Embodiment 2

[0044] Step S01: Take municipal sludge with a moisture content of 95.5%, and add ZnCl with a mass ratio of 1:1 to the sludge slurry 2 and FeCl 3 Make a solution with a mass fraction of 50% as an activator, stir for 5 minutes, and the activator is 50% of the dry weight of the sludge; then add CaO and coal powder with a mass ratio of 1:2 as a physical regulator, stir for 10 minutes, and physically adjust The agent is 60% of the dry basis weight of the sludge; after mixing, the belt filter press is used for dehydration.

[0045] Step S02: Dry the activated sludge at 45° C. for 1.5 h, then grind and sieve to obtain sludge with a particle size of 0.1-2 mm.

[0046] Step S03: at N 2 Under the atmosphere, the sieved sludge was heated to 600°C at a heating rate of 50°C / min and held for 30 minutes for pyrolysis, and then activated by steam for 60 minutes. 2 The sludge-based adsorbent is prepared by cooling to room temperature in a protected state.

[0047] The BET specific surface ...

Embodiment 3

[0051] Step S01: Take papermaking sludge with a moisture content of 90.0%, and add CaCl with a mass ratio of 2:1 to the sludge slurry 2 Make a solution with a mass fraction of 60% with KOH as an activator, stir for 5 minutes, and the activator is 65% of the dry weight of the sludge; then add CaCO with a mass ratio of 1:1 3 1. Fly ash is used as a physical regulator, stirring for 15 minutes, and the physical regulator is 50% of the dry weight of the sludge; after mixing, use a plate and frame filter press to dehydrate.

[0052] Step S02: Dry the activated sludge at 105°C for 1 hour, then grind and sieve to obtain sludge with a particle size of 0.1-2mm.

[0053] Step S03: at N 2 Under the atmosphere, the sieved sludge was heated up to 1000°C at a heating rate of 60°C / min and held for 10 minutes for pyrolysis, and then activated by steam for 180 minutes. 2 The sludge-based adsorbent is prepared by cooling to room temperature in a protected state.

[0054] The sludge-based adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com