Thermosetting type IMD film and preparation method thereof

A heat-setting and heat-curing technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as low adhesion, poor flexibility, and low light transmittance of IMD films, and achieve coating The surface of the layer is smooth and the effect of cross-linking is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

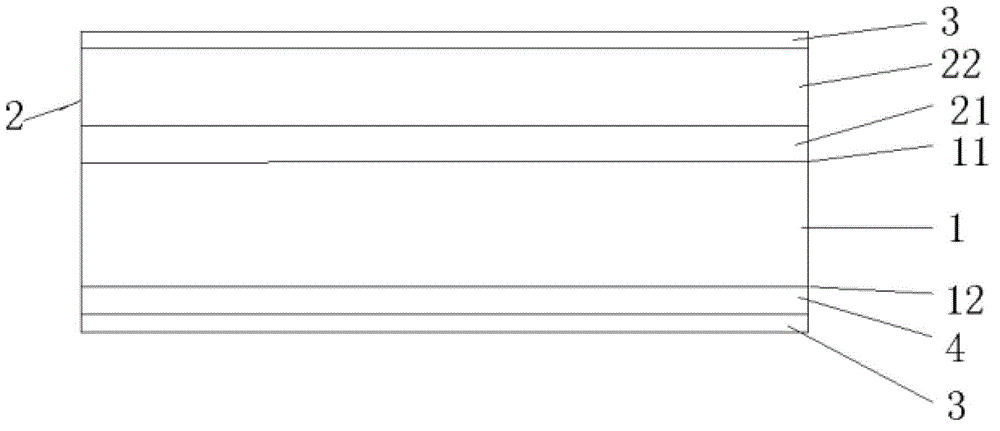

[0035] Such as figure 1 Shown: a thermosetting IMD film, including: PET base film 1, anti-scratch coating layer 2, film layer 3, and ink adhesion layer 4. An anti-scratch coating layer 2 is arranged on the upper surface 11 of the PET base film 1, a film layer 3 is arranged on the anti-scratch coating layer 2, and an ink adhesion layer 4 is arranged on the lower surface 12 of the PET base film. A film layer 3 is arranged on the layer 4 . The material of the film layer 3 is PE. The coating layer 2 is two layers. The first layer is a primer coupling layer 21 , and the second layer is a slide extrusion anti-scratch coating layer 22 . The primer coupling layer 21 is one layer. The thickness of the underlying coupling layer 21 can be selected to be 1-2 um, and in this embodiment, the thickness of the underlying coupling layer 21 is selected to be 1 um. The slide extrusion scratch-resistant coating layer 22 is one layer. The thickness of the slide extrusion anti-scratch coating...

Embodiment 2

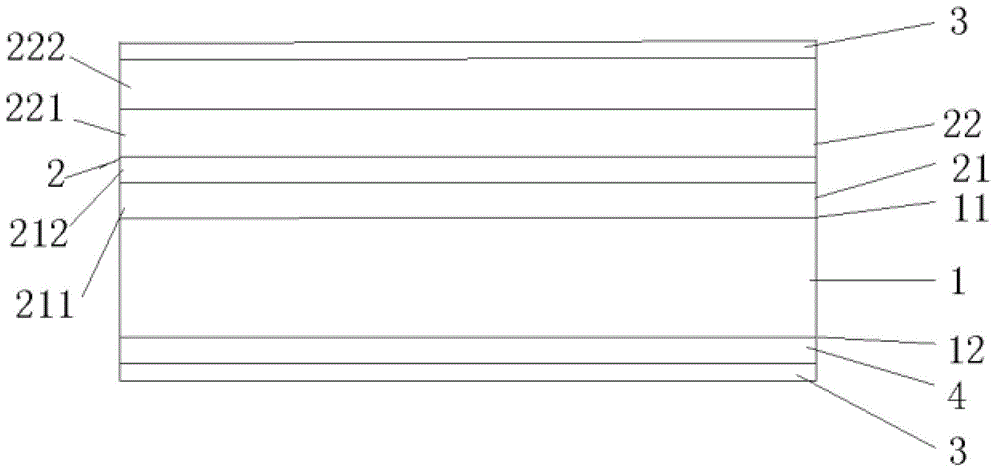

[0046] Such as image 3 Shown: a thermosetting IMD film, including: PET base film 1, anti-scratch coating layer 2, film layer 3, and ink adhesion layer 4. An anti-scratch coating layer 2 is arranged on the upper surface 11 of the PET base film 1, a film layer 3 is arranged on the anti-scratch coating layer 2, and an ink adhesion layer 4 is arranged on the lower surface 12 of the PET base film. A film layer 3 is arranged on the layer 4 . The material of the film layer 3 is PET. The anti-scratch coating layer 2 is two layers. The first layer is a primer coupling layer 21 , and the second layer is a slide extrusion anti-scratch coating layer 22 . The primer coupling layer 21 is two layers, ie 211, 212. The thickness of the underlying coupling layer 21 can be selected to be 1-2 um, and in this embodiment, the thickness of the underlying coupling layer 21 is selected to be 2 um. The slide extrusion anti-scratch coating layer 22 is two layers, namely 221,222. The thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com