Cutter for machining two sides of building stone slab

A technology of cutting tools and plates, which is applied in the field of cutting tools for processing stone plates, can solve the problems of low production and processing efficiency, difficult slotting processing, and high price of stone floors, and achieve the effects of reducing production costs, improving production efficiency, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

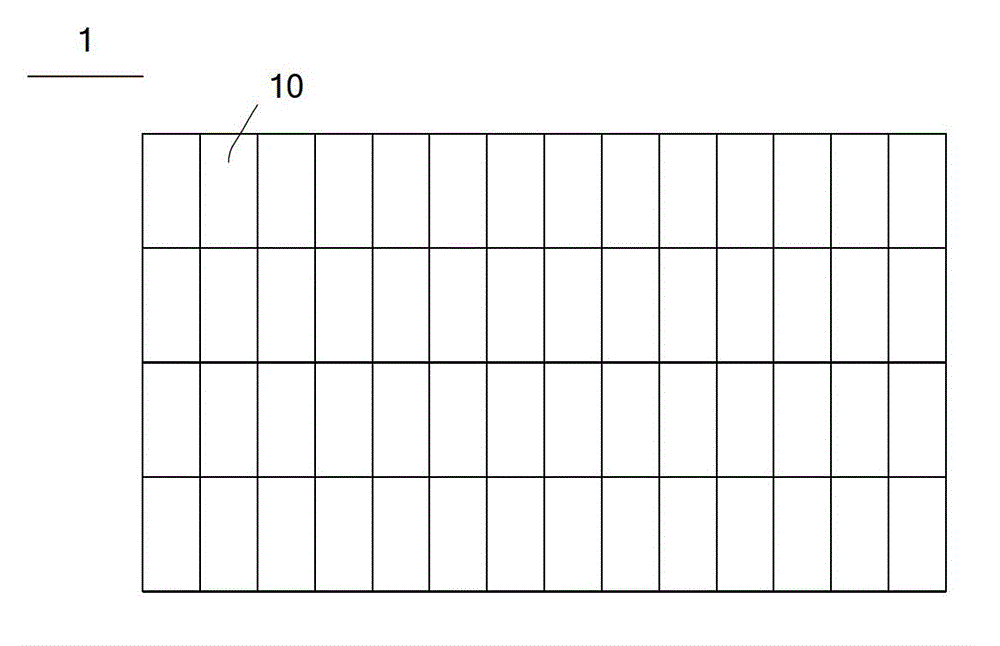

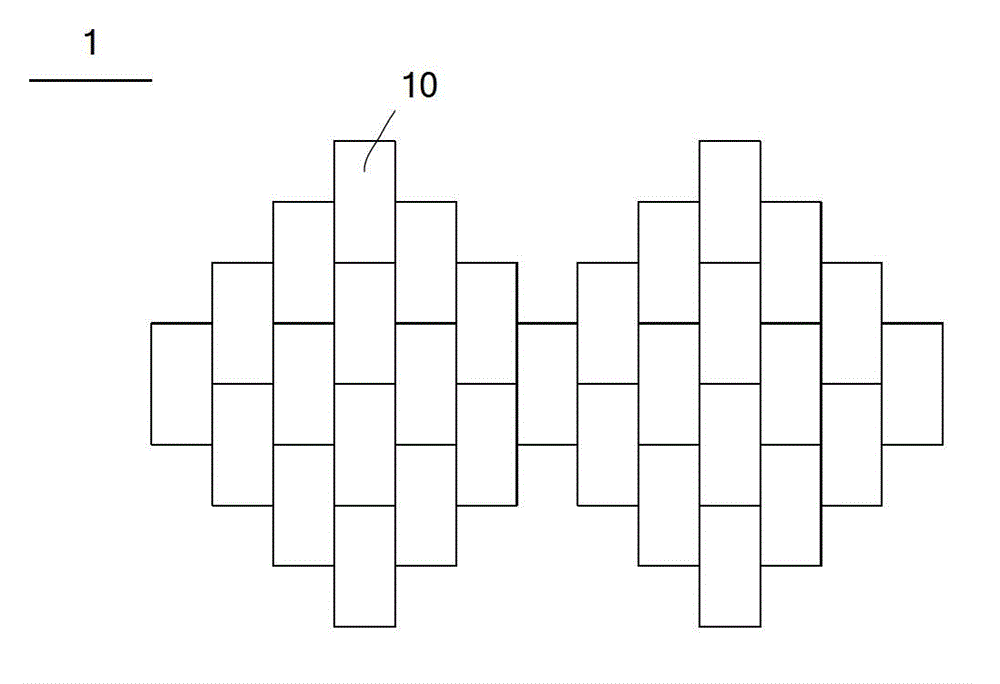

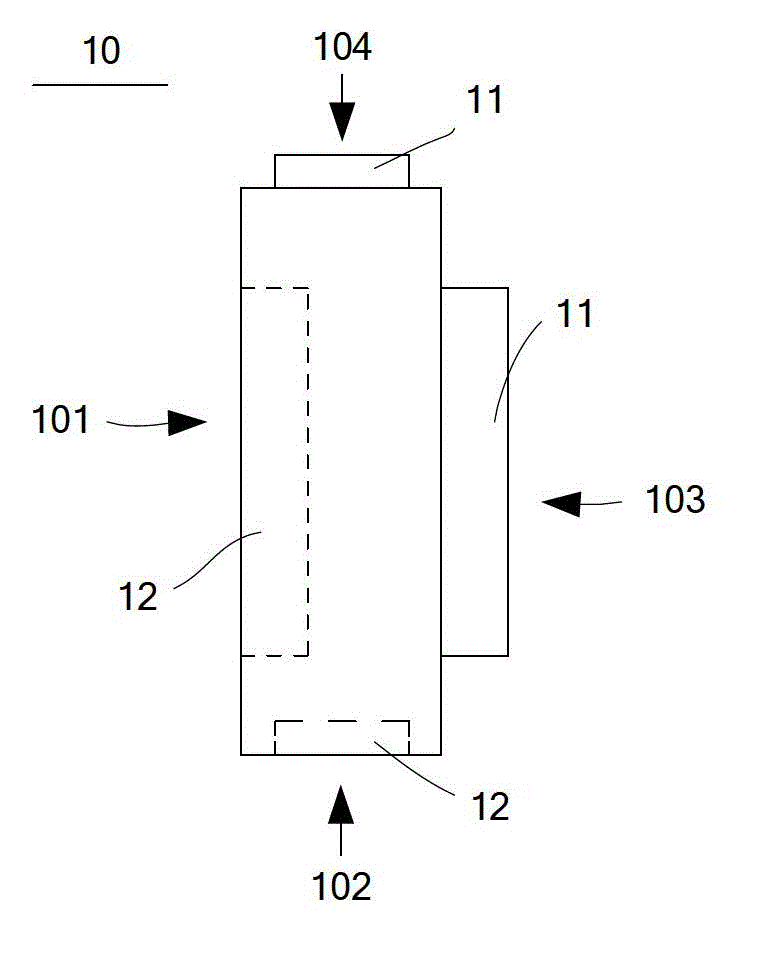

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a kind of hard floor 1, and this hard floor 1 is different from traditional wooden floor etc., has quite high hardness, can reach Mohs hardness more than 7.0, and this hard floor 1 and traditional wooden floor Compared with other materials, it has the advantages of high hardness, not easy to deform, long service life, unique visual effect, etc., so it has broad development prospects.

[0028] The materials selected for the hard floor 1 mainly include stone, ceramics and glass-cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com