Dense and thin wastewater separation device used in pre-treatment of wastewater and separation method used by same

A separation device and separation method technology, applied in the sedimentation tank and other directions, can solve the problems of inability to completely separate concentrated sewage and dilute sewage, affecting the application effect, and disturbing the sediment, and achieve the effect of small volume, energy saving and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

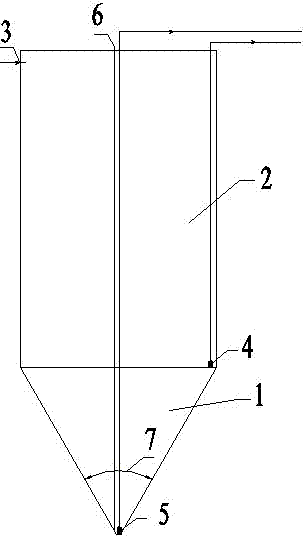

[0029] A thick-thin separation device for pre-treatment of wastewater, comprising a cone bucket 1 and a cylinder body 2, the cone bucket 1 is connected to the cylinder body 2, and the cone bucket 1 is connected to the cylinder body 2 to form a sewage treatment chamber, and the cylinder body 2 A feed inlet 3 is provided on the top, and the sewage treatment chamber includes a concentrated sewage chamber formed by the inner cavity of the cone bucket and a thin sewage chamber formed by the inner cavity of the cylinder. The bottom of the cone bucket 1 is provided with a concentrated sewage pump 5. Dilute sewage pump 4.

[0030] A preferred embodiment of the present invention is that the volume of the cone bucket 1 accounts for 10% of the total volume of the cone bucket inner cavity and the barrel inner cavity, and the cone angle 7 of the cone bucket is 60°, but it is not limited to this method.

[0031] Another preferred embodiment of the present invention is that one end of the cy...

Embodiment 2

[0039] The invention mainly includes a cone bucket 1, a cylinder body 2, a feed port 3, a dilute sewage pump 4, a concentrated sewage pump 5, a liquid level gauge 6, and the like.

[0040](1) The cone bucket 1 is located at the lower part of the device, the volume of the cone bucket 1 accounts for 20% of the entire device volume, and the cone angle 7 is 55°.

[0041] (2) The cylinder body 2 is open, and the volume accounts for 80% of the device volume. The upper part of the cylinder body is provided with a feed port 3, and the height difference from the top edge of the cylinder body is 320mm.

[0042] (3) A dilute sewage pump 4 is installed at the bottom of the cylinder to pump the dilute sewage to the dilute sewage anaerobic digestion device. The position of the dilute sewage pump 4 can be adjusted up and down according to the amount of supernatant.

[0043] (4) A concentrated sewage pump 5 is provided at the bottom of the cone bucket to pump the concentrated sewage to the co...

Embodiment 3

[0047] This embodiment is basically the same as the above-mentioned embodiment, the main difference is that the volume of the cone bucket accounts for 30% of the total volume of the inner cavity of the cone bucket and the inner cavity of the cylinder, and the cone angle of the cone bucket is 50°. The volume of the cylinder accounts for 70% of the total volume of the inner cavity of the cone bucket and the inner cavity of the cylinder. The height difference between the feed inlet and the top edge of the cylinder is 300 mm. Further, in the separation method, the time for static precipitation is 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap