Device for producing micro-nano thermocouple probe

A technology for preparing a device and a thermocouple, which is applied in the field of preparing devices for thermocouple probes, can solve the problems of complex processes, expensive thermocouples, and difficulty in obtaining ultra-miniature thermocouples, thereby simplifying the cumbersome process, increasing the success rate, Avoid the effects of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

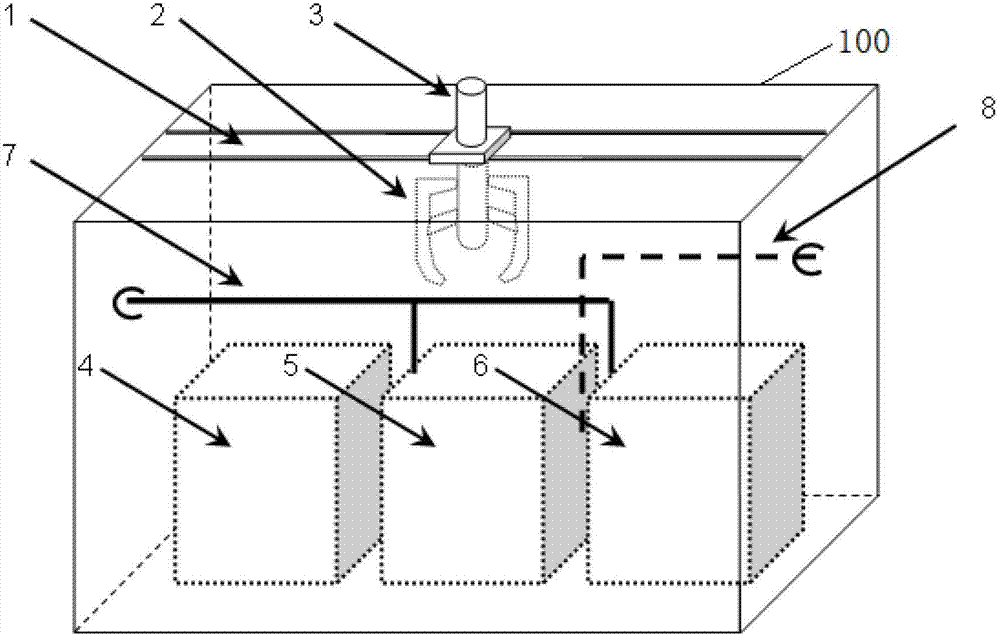

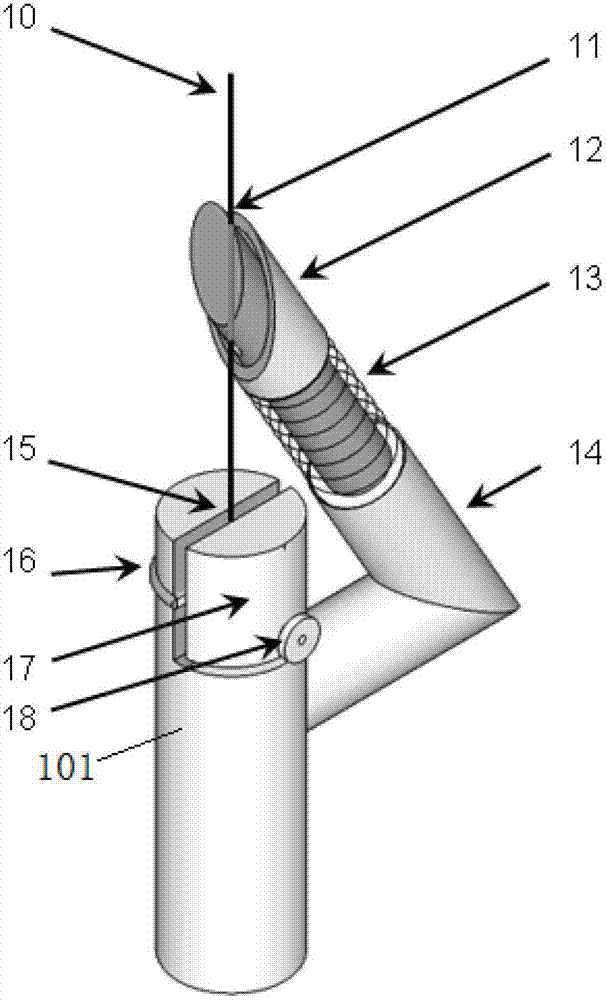

[0031] Use acetone, ethanol, and pure water to degrease and wash a tungsten wire with a length of about 5 cm and a diameter of 0.3 mm (the tungsten wire is the raw material for preparing the probe), and dry it with nitrogen gas for later use. Then fix the tungsten wire with the probe holder 9, such as image 3 shown. The end of the probe fixture shaft is fixed by mechanical claw 2, and the tungsten wire is hung upside down vertically, such as figure 2 As shown, the tungsten wire can be transferred between modules. Manipulate the mechanical claw 2 to clamp the probe holder 9 on the first metal frame 22, so that the tungsten wire can be connected to the outside world through the first metal frame to form an electrochemical corrosion circuit. The tungsten wire is used as the anode, and the copper wire is used as the cathode. 6mol / L NaOH solution, such as Figure 4 shown. The power supply 19 has the function of setting the voltage and displaying the current, providing voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com