Numerical control machine tool error real-time compensation system based on virtual instrument

A technology of virtual instrument and error compensation, which is applied in the field of compensation system, can solve the problems of inability to model training and correction, achieve the effect of increasing robustness and reliability, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific processes are given, but the protection scope of the present invention is not limited to the following embodiments.

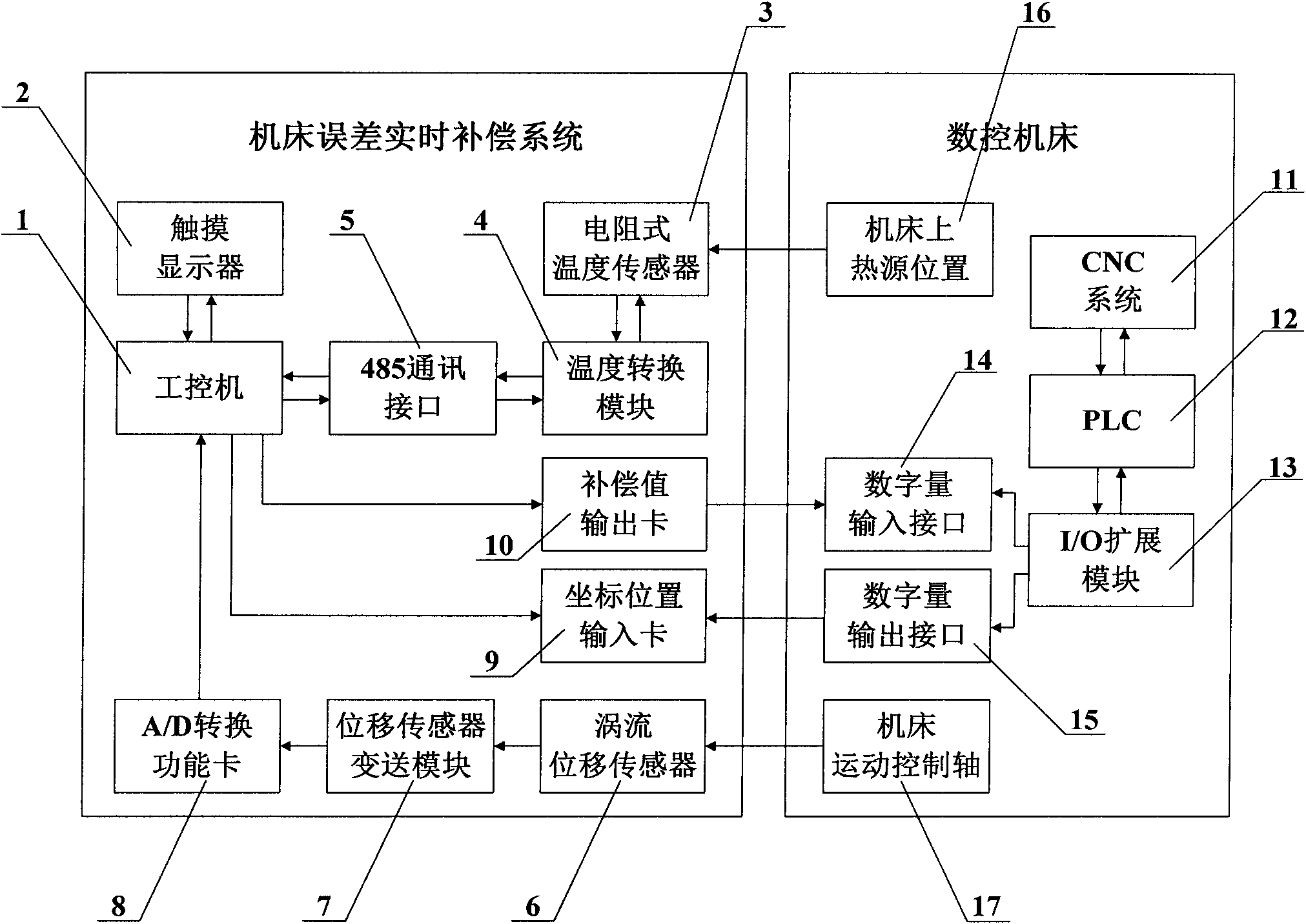

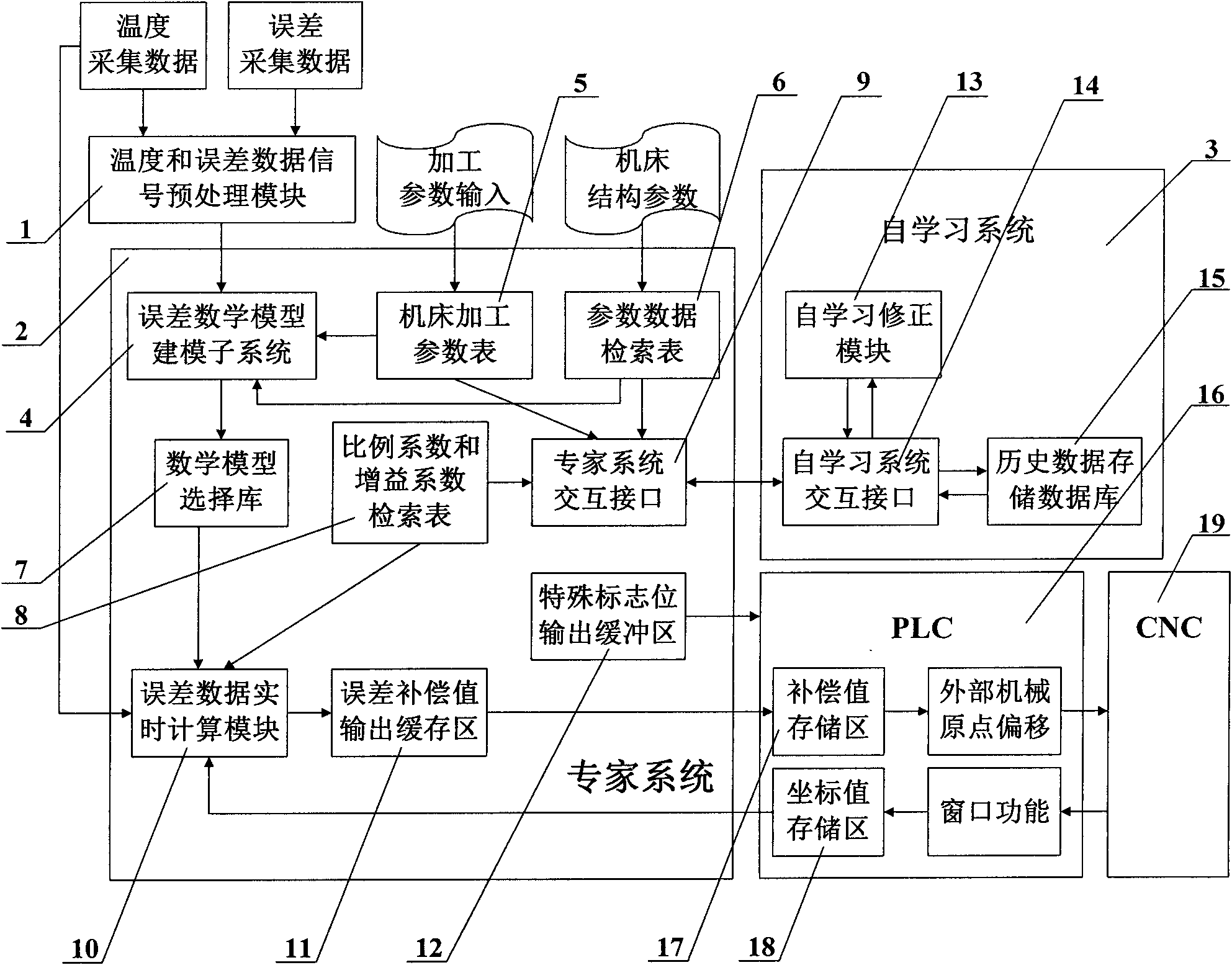

[0023] The hardware system structure of the error real-time compensation system of the present invention is as follows: figure 1 As shown, it includes: industrial computer 1, touch display 2, resistive temperature sensor 3, temperature conversion module 4, 485 communication interface 5, eddy current displacement sensor 6, displacement sensor transmission module 7, A / D conversion function card 8, Coordinate position input card 9, compensation value output card 10, CNC machine tool CNC system 11, machine tool PLC 12, I / O expansion module 13, digital input interface 14, digital output interface 15, heat source posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com