Cylinder head thermal shock test bench based on pre-tightening force, and method thereof

A technology of impact test and cylinder head heating, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as errors and reduce the credibility of test results, and achieve the effect of improving credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

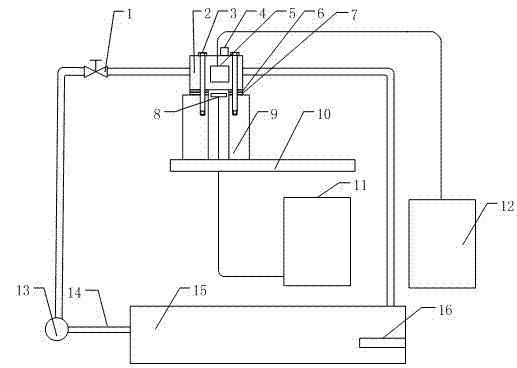

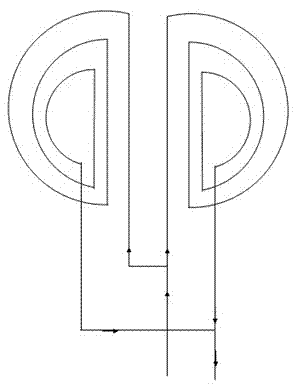

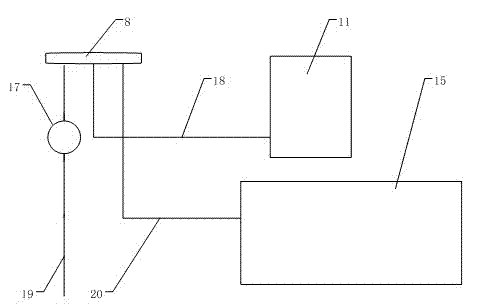

[0024] like figure 1 , 3 , 4, the cylinder head thermal shock test bench considering the pretightening force includes a test device and a control system, wherein the test device includes a first rotary switch 1, a cylinder head to be tested 2, bolts 3, a valve mechanism 4, and an infrared heater 5 , heat insulation pad 6, cylinder pad 7, induction heating coil 8, dummy body 9, fixed stand 10, induction heater control system 11, infrared heater control system 12, water pump 13, water outlet pipe 14, water tank 15, heating Device 16, second knob switch 17, electric wire 18, water inlet pipe 19, return pipe 20, first handle switch 21, water inlet solenoid valve 22, second handle switch 23, thermostat 24 and thermocouple;

[0025] A valve mechanism 4 is installed on the cylinder head 2 to be tested, and the cylinder head 2 to be tested, the heat insulation pad 6, the cylinder pad 7, and the dummy body 9 are connected in sequence and fixed by bolts 3. The front and rear sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com