Tunnel curing barn adopting humiture subdivision control of alternate wind direction

A segmented control, tunnel-type technology, applied in the field of tunnel-type baking room, can solve the problems of not being able to take care of the temperature and humidity changes in the tunnel, and the inability to achieve the best baking temperature curve and humidity curve, etc., to shorten the heat conduction distance and shorten the drying time. The effect of reducing the baking time and heat conduction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

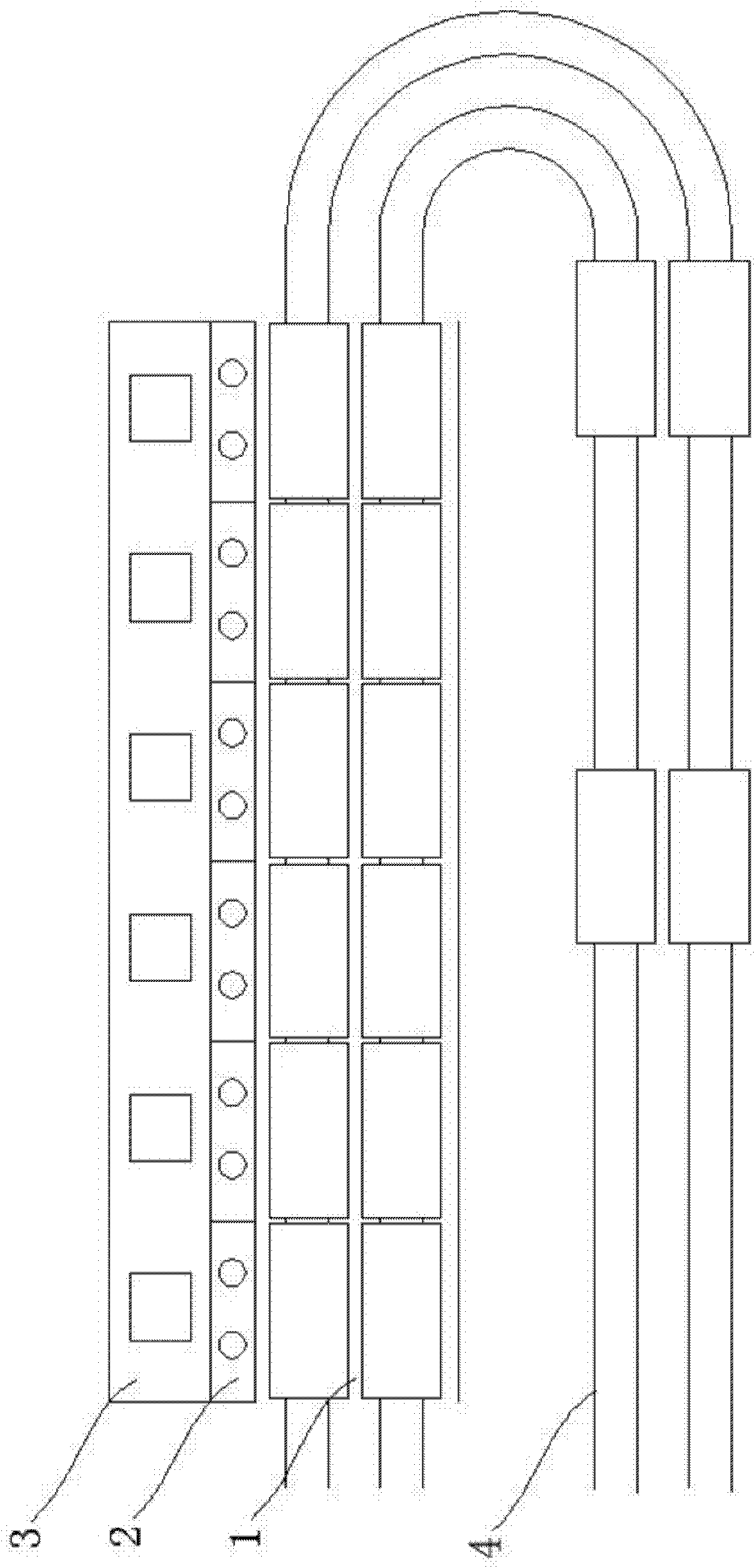

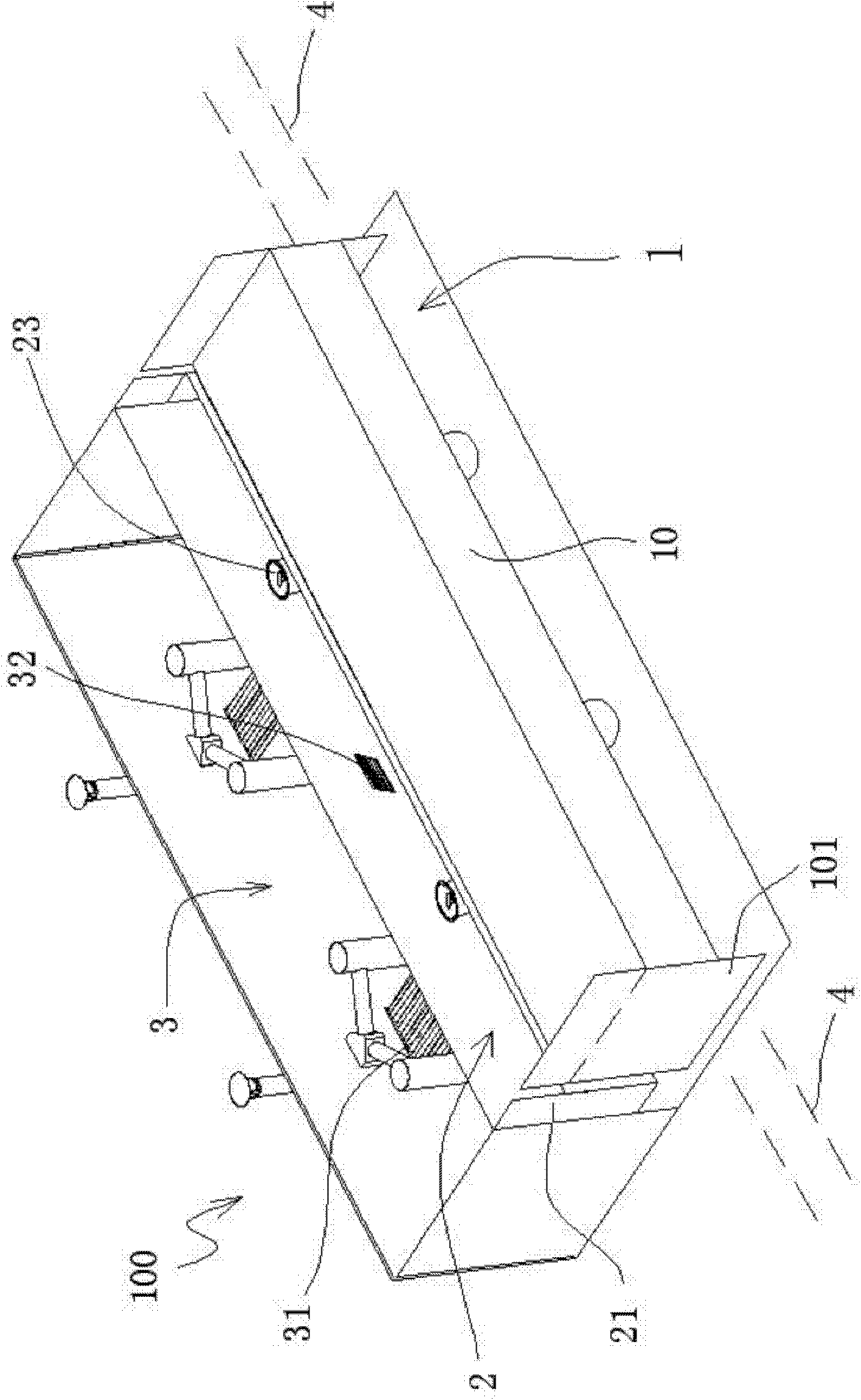

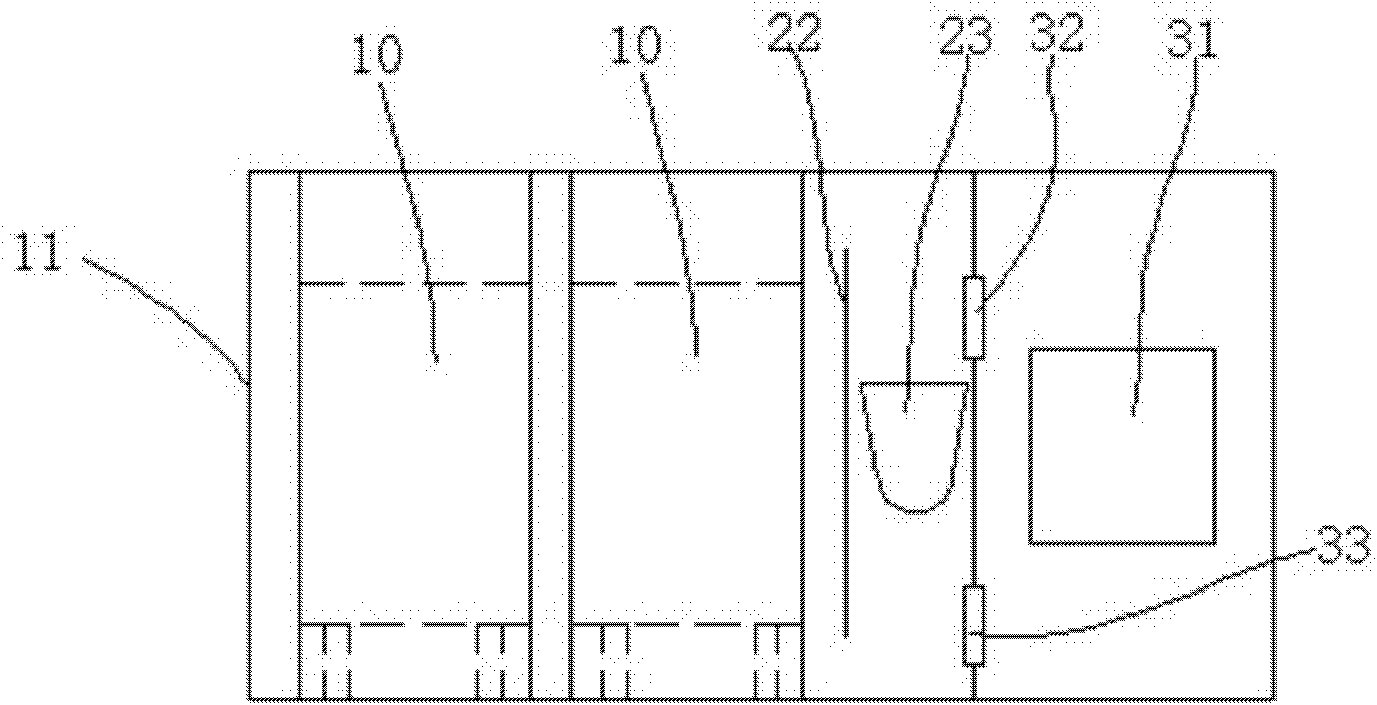

[0026] Such as figure 1 As shown, the present invention is a tunnel-type barn with segmental control of temperature and humidity using alternating wind directions. The tunnel-type barn is sequentially distributed with a plurality of independent work rooms, and each work room includes a barn room 1. An air-mixing layer 2 and a hot-air room 3, wherein each workshop can be provided with a hot-air room 3, or multiple workshops can share at least one hot-air room 3. There is at least one material trolley 10 passing through the baking room 1 each time, and each material trolley 10 moves a distance between the baking rooms. A track 4 is also arranged in the said baking room 1, which runs through each working room. The material tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com