Anti-vibration alloy material for nuclear power station steam generator and preparation process thereof

A technology of steam generators and alloy materials, which is applied in the field of anti-vibration materials, can solve the problems of manpower, financial resources and time waste, increase the risk of maintenance personnel being exposed to radioactive radiation, etc., achieve extended service life, reasonable composition design, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

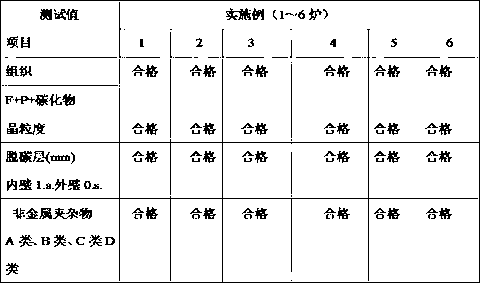

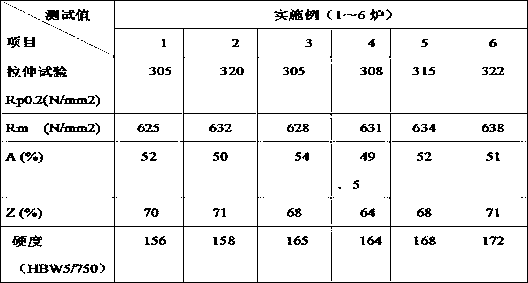

Examples

Embodiment Construction

[0034]In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

[0035] An anti-vibration alloy material for a steam generator in a nuclear power plant, which contains the following components by weight percentage: C: 0.015-0.030%; Si: 0.05-0.5%; Mn: 0.05-0.50%; P: ≤0.015%; S: ≤0.010%; Cr: 28.0~31.0%; Ni: 58.0~63%; Cu: 0.001~0.20%; Ti: 0.005~0.5%; Al: 0.005~0.5%; Fe: 7.0~11.0%; Re: 0.01~ 1.0%; Nb: 0.001~0.10%; Mo: 0.001~0.10%; the balance is unavoidable impurities; wherein the purity of Si, Mn, Cr, Ni, Nb, Mo, Cu, Ti, Al, Fe is greater than 99%, the rare earth Re is a mixed rare earth metal, its purity is greater than 99%, and the block size is 60*100mm.

[0036] The preparation method of an anti-vibration alloy material for a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation after break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com