A kind of antirust metal cutting fluid and preparation method thereof

A technology of metal cutting fluid and dibasic acid ester, which is applied in the field of metallurgical auxiliary materials processing, and can solve problems such as reduced production efficiency, red tide, and deterioration of cutting fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

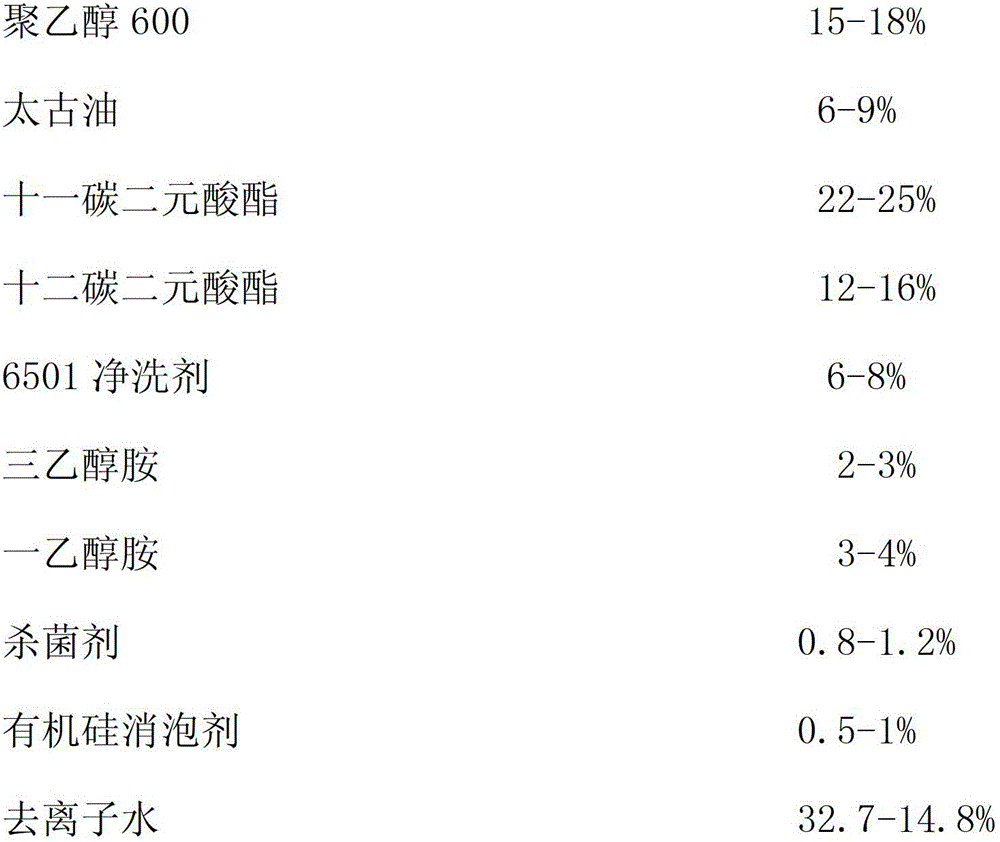

[0028] The following components of the main composition are by mass percentage:

[0029]

[0030] The synthesis method of the product is to start the stirring of the reaction kettle, and add the following substances in the reaction kettle according to the order:

[0031]

[0032] The finished product can be obtained by compounding. The mixture of straight chain undecane dibasic acid ester and straight chain dodecane dibasic acid ester in the above product system plays an excellent lubricating role in the whole product system and can produce superior The synergistic effect makes the performance indicators of the products meet a higher requirement.

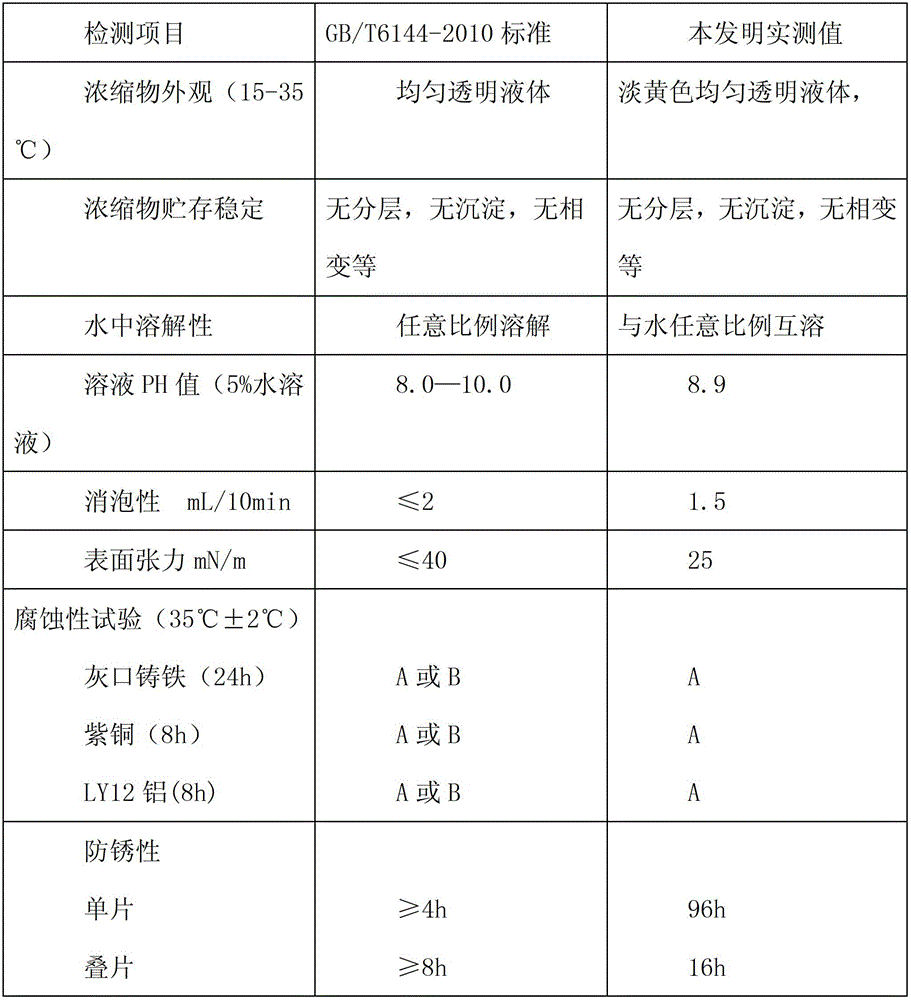

[0033] Product performance testing (according to national GB / T614-2010 standard):

[0034] Take more than 5 parts of synthetic cutting fluid, add 95 parts of water, the detection performance is as follows:

[0035]

[0036]

Embodiment 2

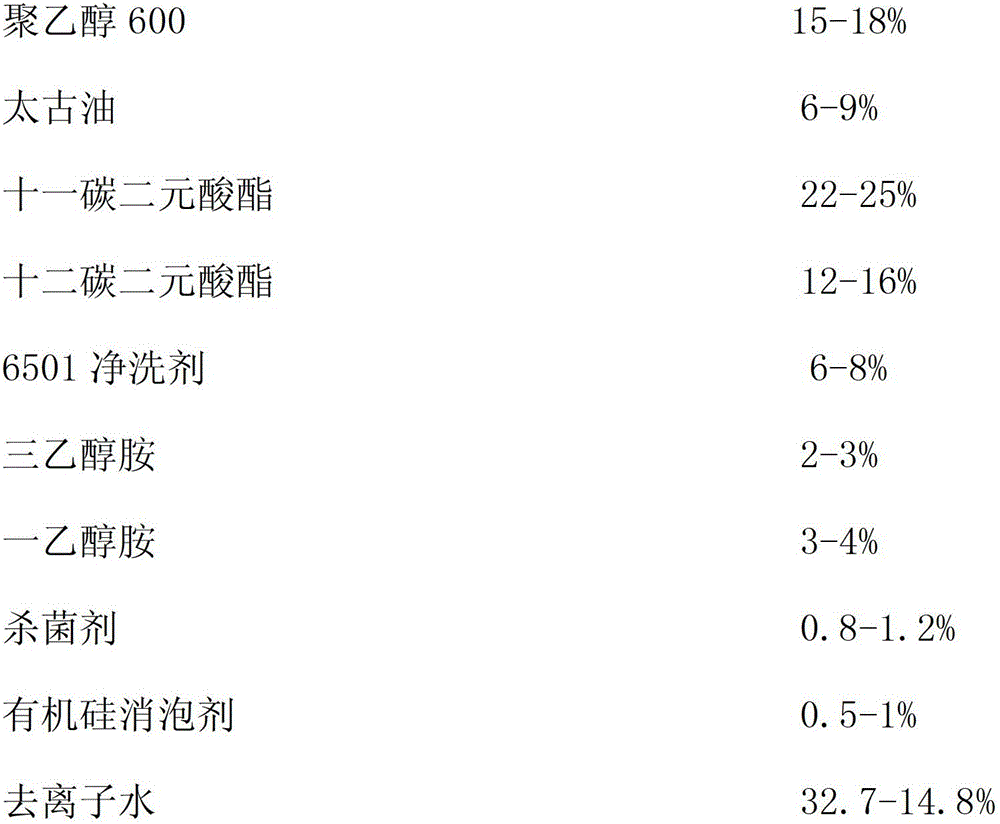

[0038] Main composition (the following components are by mass percentage):

[0039]

[0040] The synthesis method of the product is as follows: start the stirring of the reaction kettle, and add the following substances into the reaction kettle in sequence and in quantity.

[0041]

[0042]

[0043] The finished product can be obtained by compounding. The mixture of undecyl-carbon dibasic acid ester and octadecyl-carbon dibasic acid ester in the above product system has an excellent lubricating effect in the entire product system and can produce superior synergistic effects. So that the performance indicators of the product can meet a higher requirement.

[0044] Product performance testing (according to national GB / T614-2010 standard):

[0045] Take more than 5 parts of synthetic cutting fluid, add 95 parts of water, the detection performance is as follows:

[0046]

[0047]

[0048] Since no toxic and harmful heavy metal ions are used in the above examples, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com