Cubic boron nitride fiber abrasive particles and preparation method thereof

A technology of cubic boron nitride and abrasive grains, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as failure to achieve expected results, and achieve improved grinding efficiency and quality, good wear resistance and self-sharpening , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

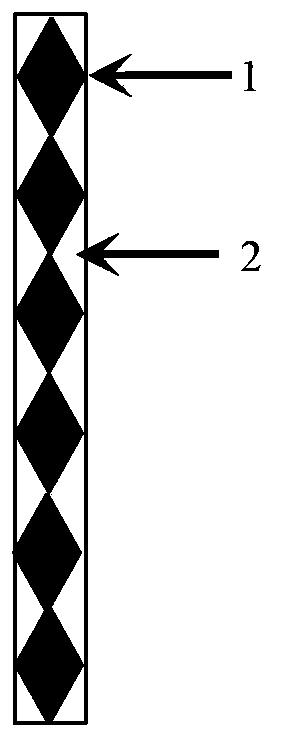

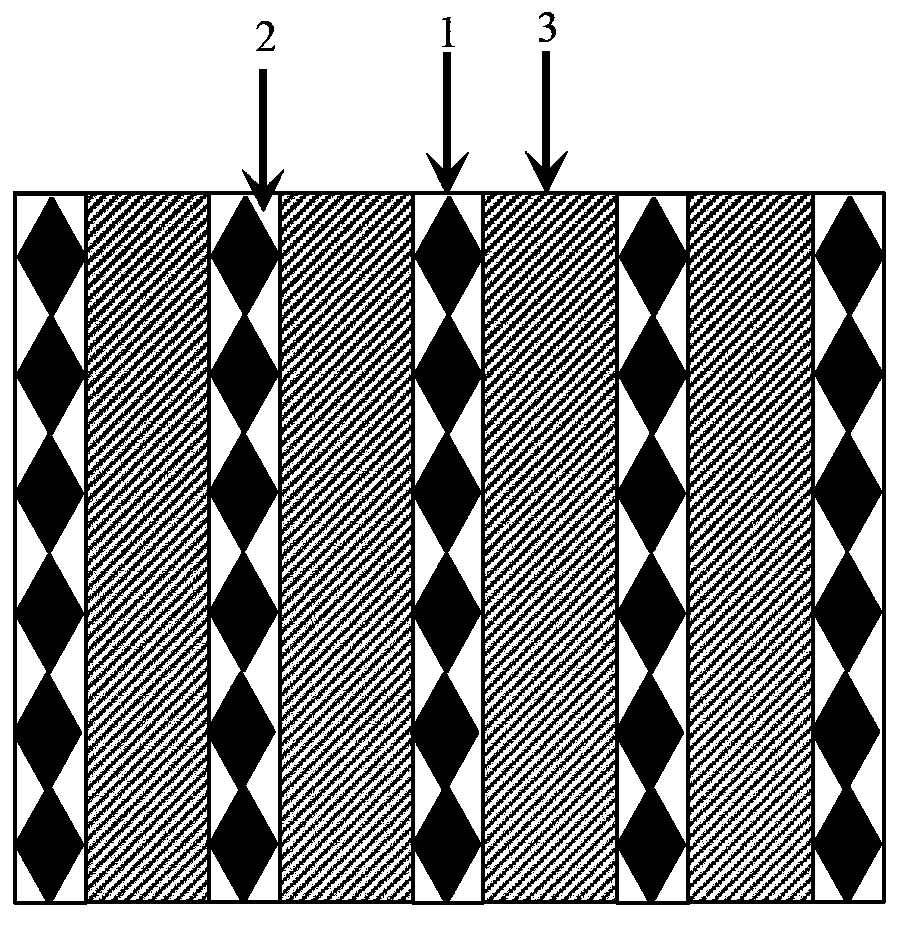

[0034] A cubic boron nitride fiber abrasive grain, comprising two parts of 30% by weight cubic boron nitride abrasive grain and 70% by weight binder, wherein the surface layer of the cubic boron nitride abrasive grain is coated with titanium, and the thickness of the coating is 8 μm; the binder The composition and weight percentage content are: Al 2 o 3 Powder 18%, B 2 o 3 Powder 30%, Na 2 O powder 7%, SiO 2 Powder 45%.

[0035]The preparation method of cubic boron nitride fiber abrasive grains: mix the titanium-coated CBN abrasive grains with the binder, add an appropriate amount of dextrin, and stir evenly; then put the mixed raw materials into and fill the stainless steel mold groove; then Put the mold and fiber abrasive grains into a heating furnace and bake at 110°C for 130 minutes, then release the mold to obtain a CBN fiber abrasive grain blank; then put the blank into a vacuum sintering furnace (vacuum degree not less than 10 -2 Pa), the temperature of the reacti...

Embodiment 2

[0036] Example 2 is different from Example 1 in that the titanium-coated CBN abrasive grains are 35% by weight, and the binder is 65% by weight. The composition and weight percentage of the binder are: Al 2 o 3 Powder 16%, B 2 o 3 Powder 32%, Na 2 O powder 10%, SiO 2 Powder 42%.

Embodiment 3

[0037] Example 3 is different from Example 1 in that the titanium-coated CBN abrasive grains are 40% by weight, and the binder is 60% by weight. The composition and weight percentage of the binder are: Al 2 o 3 Powder 20%, B 2 o 3 Powder 28%, Na 2 O powder 3%, SiO 2 Powder 49%.

[0038] The content of raw materials used in Examples 4 to 6 and the stepwise heating and cooling process are the same as those in Examples 1 to 3, but the coating metal on the surface of the CBN is chromium with a thickness of 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com