Novel nitrogen fertilizer

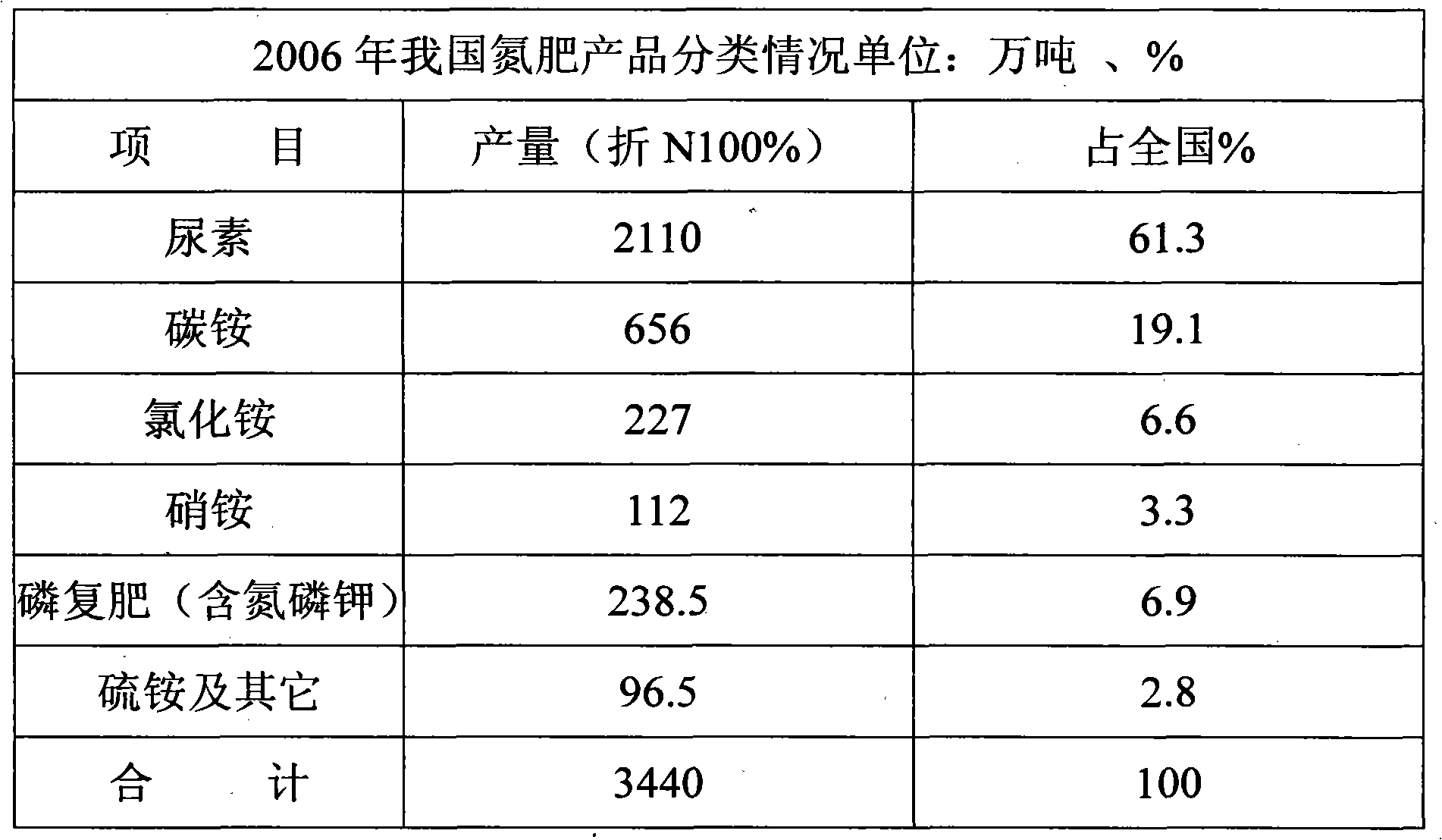

A nitrogen fertilizer, a new type of technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as crop efficacy limitations, fruit and vegetable malnutrition, crop lengthening, etc., to prevent excessive growth of energy prices, reduce waste and pollution. , the effect of reducing the dependence of urea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the process of producing 100 tons of nitrogen fertilizer, add nitrogen fertilizer containing 12 tons of amide nitrogen, nitrogen fertilizer containing 16 tons of ammonium nitrogen, 0.5 tons of zinc as zinc oxide, 0.8 tons of magnesium as magnesium oxide, and 0.5 tons of boron oxide The total boron, 12 tons of bentonite, 0.05 tons of diethyl hexanoate, 1 ton of nitrate nitrogen, 100 tons of total weight, are made into granules or powders, and one of the nitrogen fertilizer finished products of proportioning in the present invention is obtained.

Embodiment 2

[0049] In the process of producing 100 tons of nitrogen fertilizer, add nitrogen fertilizer containing 9 tons of amide nitrogen, nitrogen fertilizer containing 16 tons of ammonium nitrogen, 0.6 tons of zinc as zinc oxide, 1 ton of magnesium as magnesium oxide, and 0.6 tons of boron oxide Total boron, 14 tons of bentonite, 0.06 tons of diethyl hexanoate, 1.5 tons of nitrate nitrogen, 100 tons of total weight, are made into granules or powders, and then one of the nitrogen fertilizer finished products of proportioning in the present invention is obtained.

Embodiment 3

[0051] In the process of producing 100 tons of nitrogen fertilizer, add nitrogen fertilizer containing 7 tons of amide nitrogen, nitrogen fertilizer containing 18 tons of ammonium nitrogen, 0.7 tons of zinc as zinc oxide, 1.6 tons of magnesium as magnesium oxide, and 0.7 tons of boron oxide Total boron, 13 tons of bentonite, 0.08 tons of diethyl hexanoate, 2 tons of nitrate nitrogen, 100 tons of gross weight, are made into granules or powders, and then a kind of nitrogen fertilizer finished product of proportioning among the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com