Method for defluorination, purification and separation of wet-process phosphoric acid

A wet-process phosphoric acid, purification and separation technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as high content of phosphorus pentoxide, low purity of sodium fluorosilicate, harsh working environment, etc., to achieve filtration The effect of low cake moisture, reduced labor intensity and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The quality indicators of wet-process phosphoric acid are shown in Table 1:

[0041] Table 1 Example 1 wet-process phosphoric acid index

[0042] P 2 o 5

density

Solid content

F

SO 3

%

g / ml

%

%

%

40.50

1.47

0.5

1.40

1.50

[0043] 1. Wet process phosphoric acid defluorination reaction

[0044] Wet-process phosphoric acid from phosphoric acid storage tanks, P 2 o 5 Concentration 40.50%, density 1.47g / ml, solid content 0.5%, F content 1.40%, SO 3 1.50%, temperature 45°C; at 31M 3 The flow rate per hour enters the defluorination reaction tank, and then a reaction amount of defluorination agent is added into the defluorination reaction tank to react to form a defluorination slurry.

[0045] 2. Solid-liquid separation of defluorinated slurry

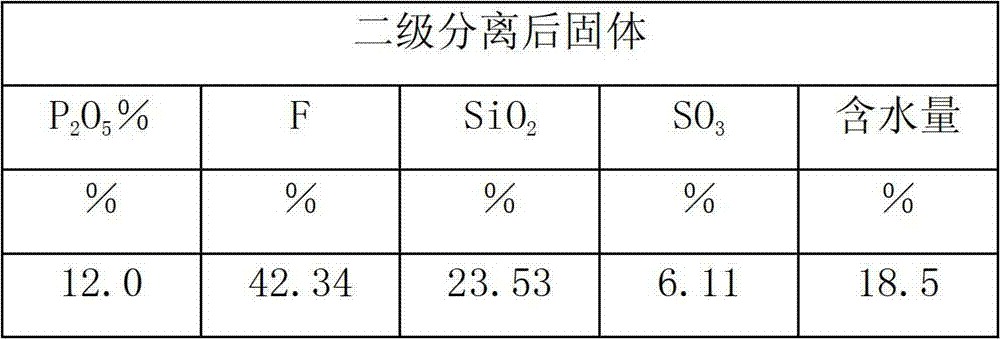

[0046]The defluorinated slurry is pumped into the first-stage horizontal screw discharge sedimentation centrifuge for filtrati...

Embodiment 2

[0057] The quality indicators of wet-process phosphoric acid are shown in Table 4:

[0058] Table 4 Example two wet-process phosphoric acid indicators

[0059] P 2 o 5 %

density

Solid content

F

SO 3

%

g / ml

%

%

%

35.00

1.40

0.8

1.60

1.20

[0060] 1. Wet process phosphoric acid defluorination reaction

[0061] Wet-process phosphoric acid from phosphoric acid storage tanks, P 2 o 5 Concentration 35.00%, density 1.40g / ml, solid content 0.8%, F content 1.60%, temperature 43°C; at 33.5M 3 The flow rate per hour enters the defluorination reaction tank, and then a reaction amount of defluorination agent is added into the defluorination reaction tank to react to form a defluorination slurry.

[0062] 2. Solid-liquid separation of defluorinated slurry

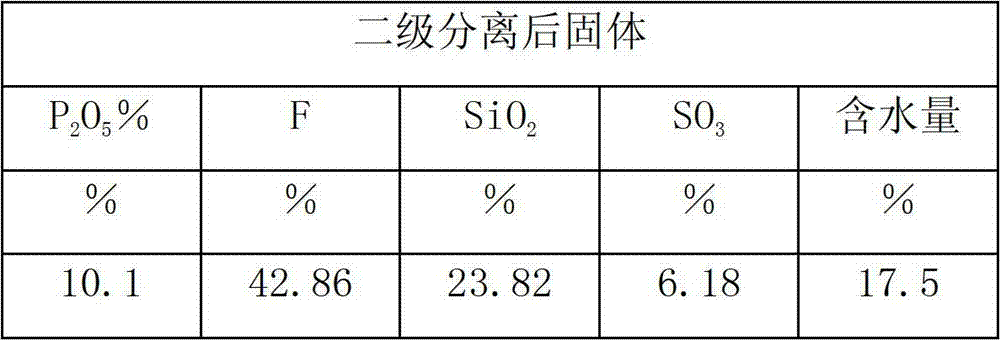

[0063] The defluorinated slurry is pumped into the first-stage horizontal screw discharge sedimentation centrifuge for filtratio...

Embodiment 3

[0074] The quality indicators of wet-process phosphoric acid are shown in Table 7:

[0075] Table 7 Example three wet-process phosphoric acid indicators

[0076] P 2 o 5 %

density

F

SO 3

%

g / ml

%

%

%

49.80

1.60

1.1

0.85

1.82

[0077] 1. Wet-process phosphoric acid defluorination reaction;

[0078] Wet-process phosphoric acid from phosphoric acid storage tanks, P 2 o 5 Concentration 49.80%, density 1.60g / ml, solid content 1.1%, F content 0.85%, SO3 1.82%, temperature 40°C; at 30.0M 3 The flow rate per hour enters the defluorination reaction tank, and then a reaction amount of defluorination agent is added into the defluorination reaction tank to react to form a defluorination slurry.

[0079] 2. Solid-liquid separation of defluorinated slurry;

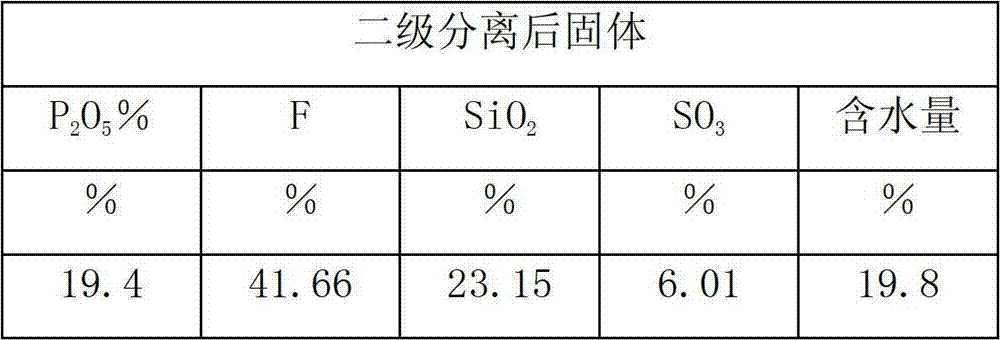

[0080] The defluorinated slurry is pumped into the first-stage horizontal screw discharge sedimentation centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com