Linkage production method and device for rubber hose extrusion

A production method and a technology of a lead-out device, which are applied in the field of rubber hose cold feeding extrusion linkage production line, can solve the problems of non-conformity of tube blank size, uneven heating temperature, and uneven tube wall thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0171] The present invention is described below in conjunction with specific embodiments, but is not limited to the technical solutions of the listed embodiments.

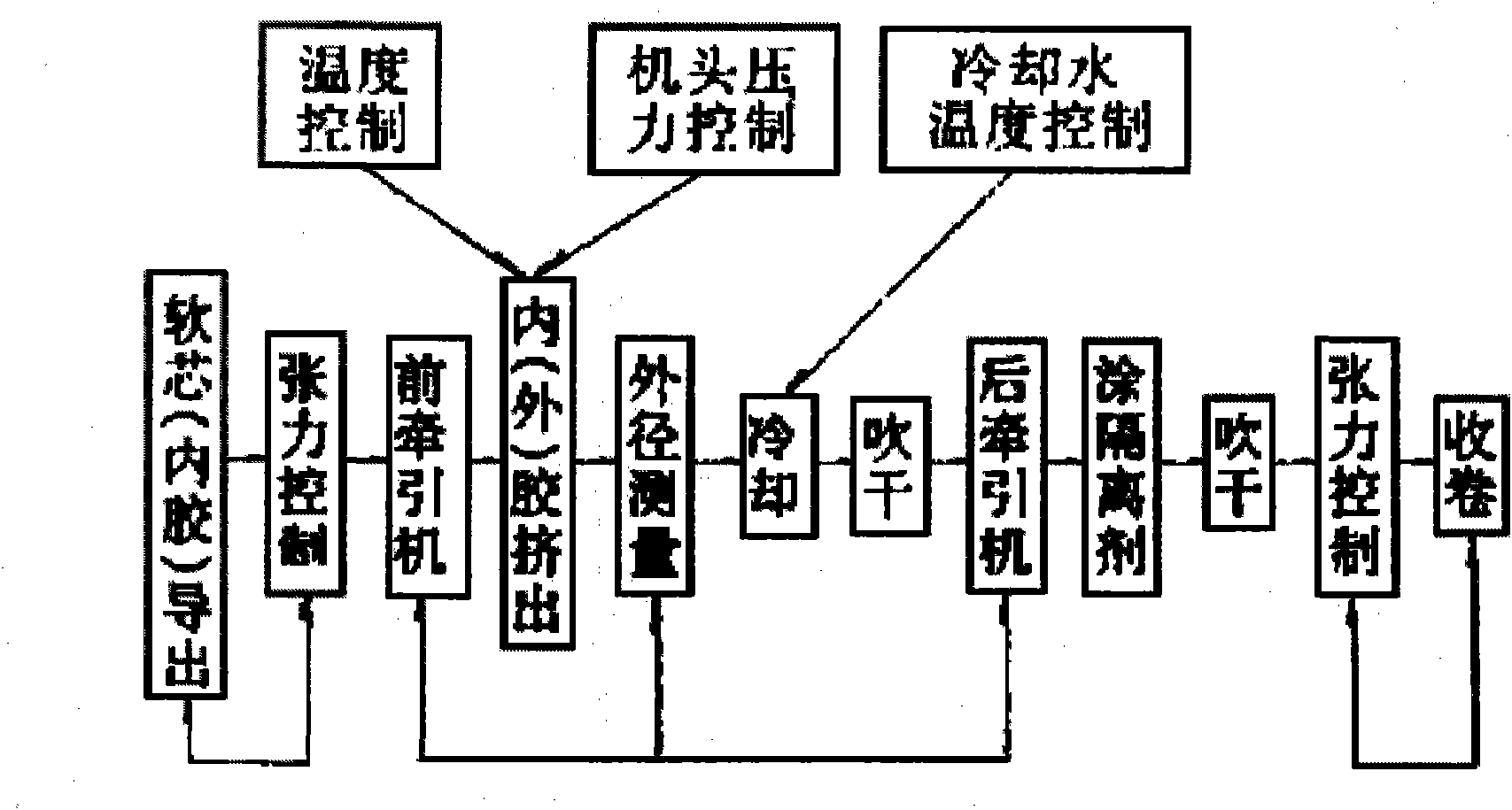

[0172] An automatic rubber hose extrusion linkage production line is designed, such as figure 1 As shown, including: 1. Soft core export device; 2. Front tractor; 3. Cold feed extruder; 4. Power cabinet; 5. Temperature control system; 6. Caliper; 7. Printing machine; 8 1. Cooling water device; 9. Rear tractor; 10. Separator coating machine; 11. Double-shaft winder; 12. Main console; 13. Tension device.

[0173] Its production process is as figure 2 Shown: Including the tension control of the inner rubber extrusion, the pressure and temperature control inside the machine head, the outer diameter detection of the inner and outer rubber layer extrusion, the cooling water temperature control, the synchronous coordination control of the front and rear tractors, and the tension control and shrinkage after forming. rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com