High precision high speed closed-loop control nitrogen auxiliary shooting glue injection molding machine

A closed-loop control and injection molding machine technology, which is applied in the field of injection molding machines, can solve problems affecting the accuracy of injection molding products, poor control of displacement accuracy, and self-heaviness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

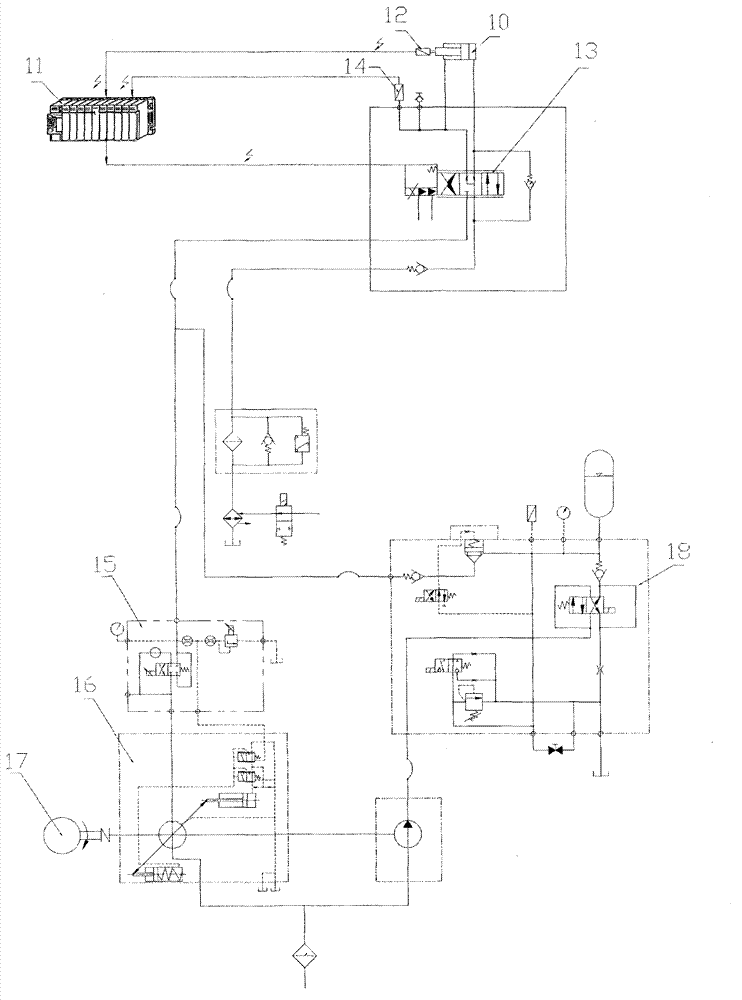

[0016] Please refer to figure 2 , figure 2 It is a schematic diagram of the oil circuit structure of the high-precision high-speed closed-loop control nitrogen-assisted injection molding machine of the present invention. figure 2 Among them, the high-precision high-speed closed-loop control nitrogen-assisted injection molding machine of the present invention includes an injection cylinder 10, a control unit 11, a speed sensor 12 connected between the injection cylinder 10 and the control unit 11, a servo valve 13, and a servo valve 13 connected to the The pressure sensor 14 between the control units 11, the PQ valve 15 used to adjust the pressure and flow of the injection molding machine, the variable pump 16 used to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com