Servocontrol semi-solid state magnesium alloy high speed injection molding machine

An injection molding machine and servo control technology, which is applied in the field of servo-controlled semi-solid magnesium alloy high-speed injection molding machines, can solve the problems that the injection mechanism does not have a check valve, and achieve the effects of low manufacturing cost, easy debugging, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

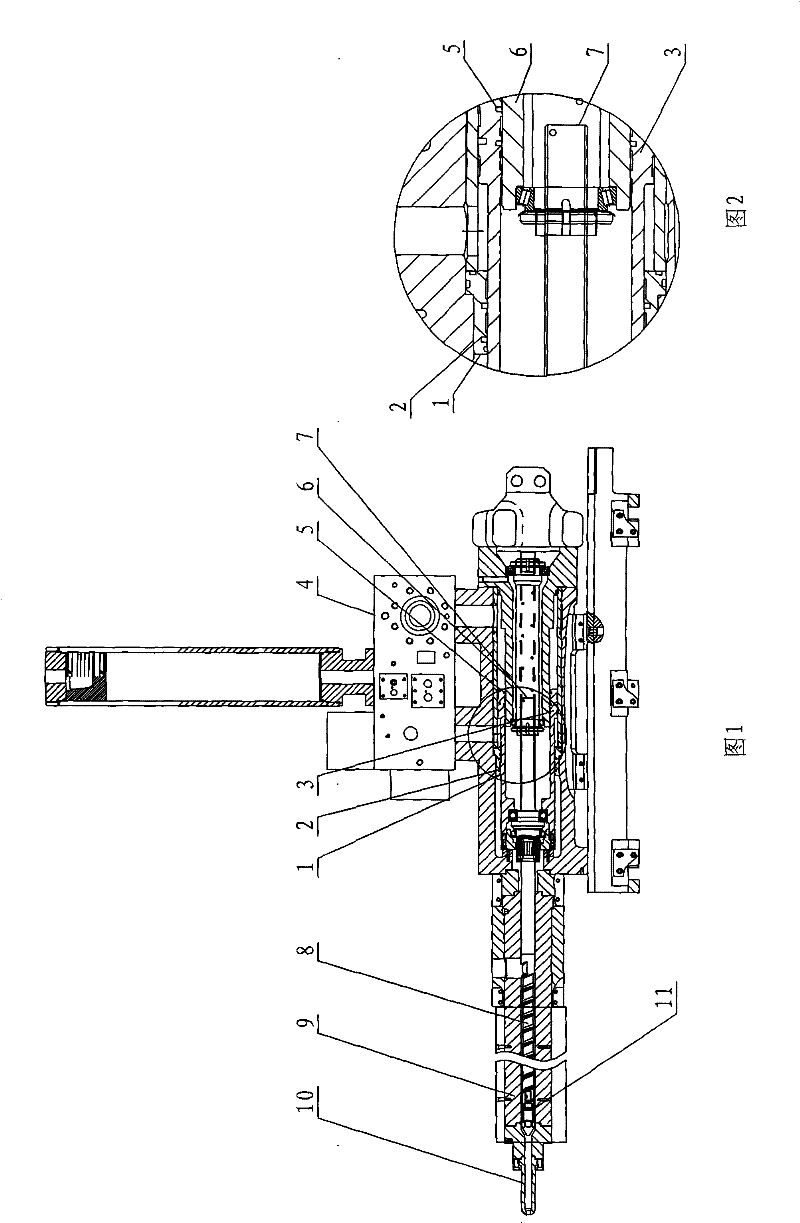

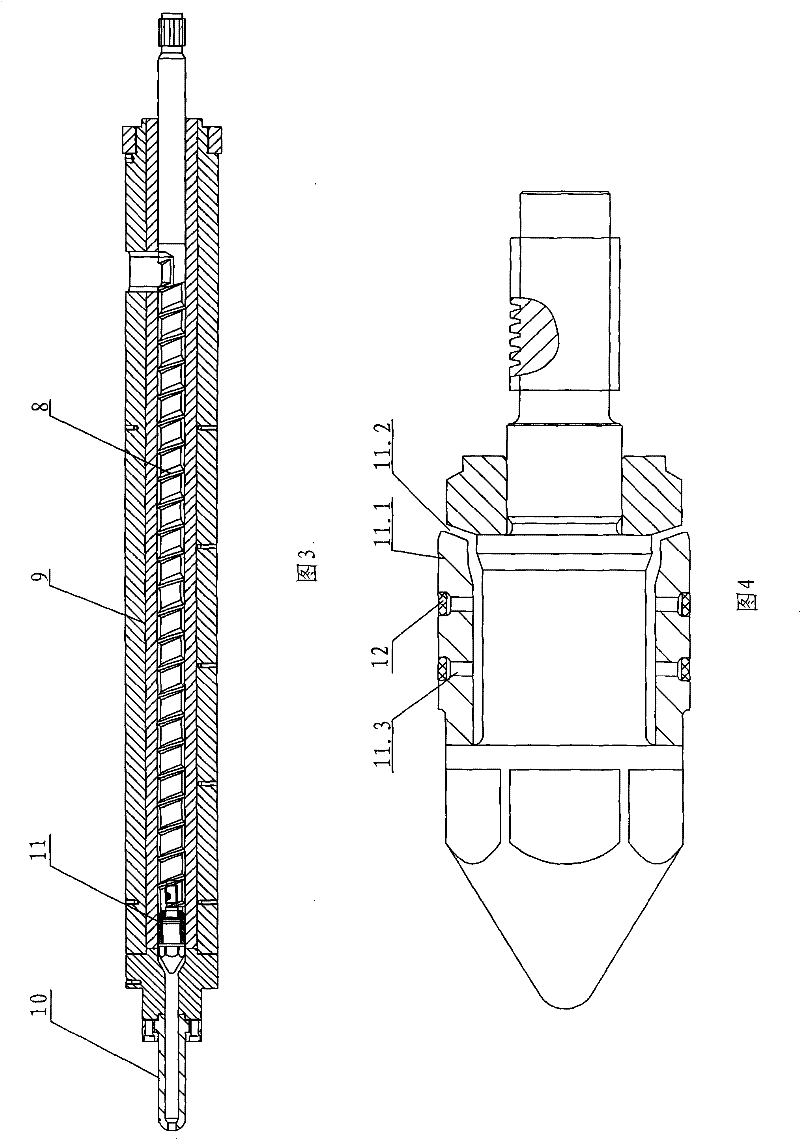

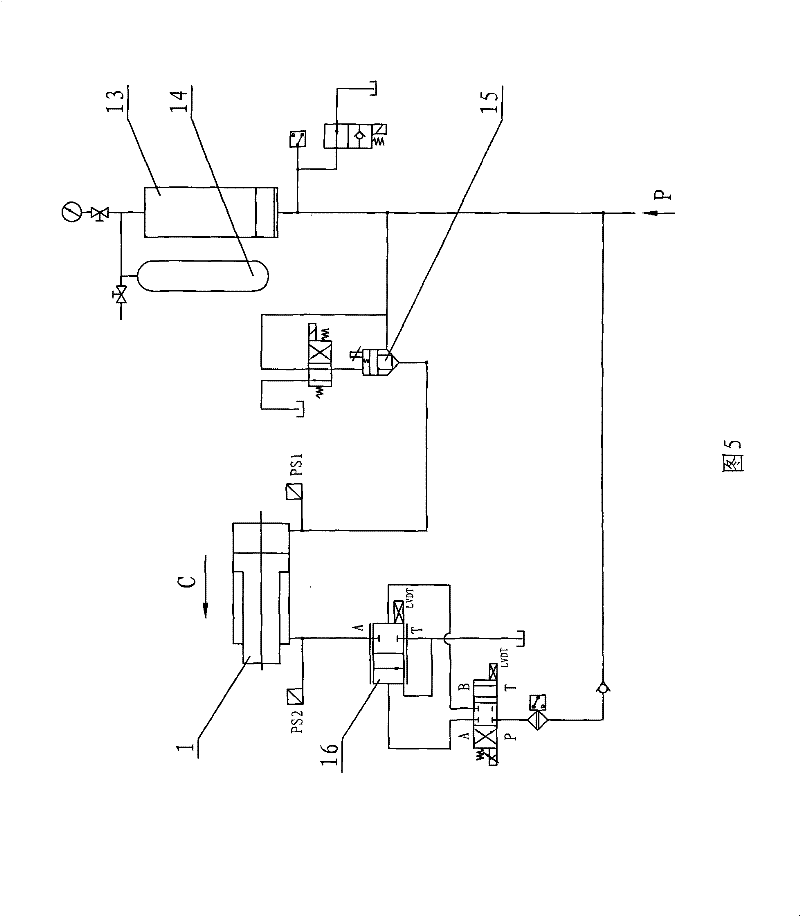

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] see Figure 1-Figure 4 , the servo-controlled semi-solid magnesium alloy injection molding machine, the injection cylinder 1 is provided with a hollow floating piston 3, the first low-friction combined oil seal 2 is provided between the hollow floating piston 3 and the inner wall of the cylinder, the hollow floating piston 3 and the positioning sleeve A second low-friction combined oil seal 5 is arranged between the barrels 6 . The oil inlet chamber and the oil outlet chamber of the oil injection cylinder 1 are directly connected with the oil injection control board 4 . When the machine is working, the hollow floating piston 3 can drive the feeding screw 8 to do reciprocating linear motion through the connecting seat 7 . The feeding system is equipped with a feeding screw 8 assembly capable of forming a semi-solid magnesium alloy structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com