Extrusion molding mould and molding method of large-length-width-ratio aluminum alloy rectangular box-shaped piece

A technology for extrusion forming and box-shaped parts, applied in the direction of metal extrusion dies, etc., can solve the problems such as the increase of allowable deep drawing deformation, the phenomenon of the lug at the end of the box-shaped part, and the difficulty in controlling the lug defect, and achieve a single The effect of low cost of parts, improvement of lug defects, and improvement of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

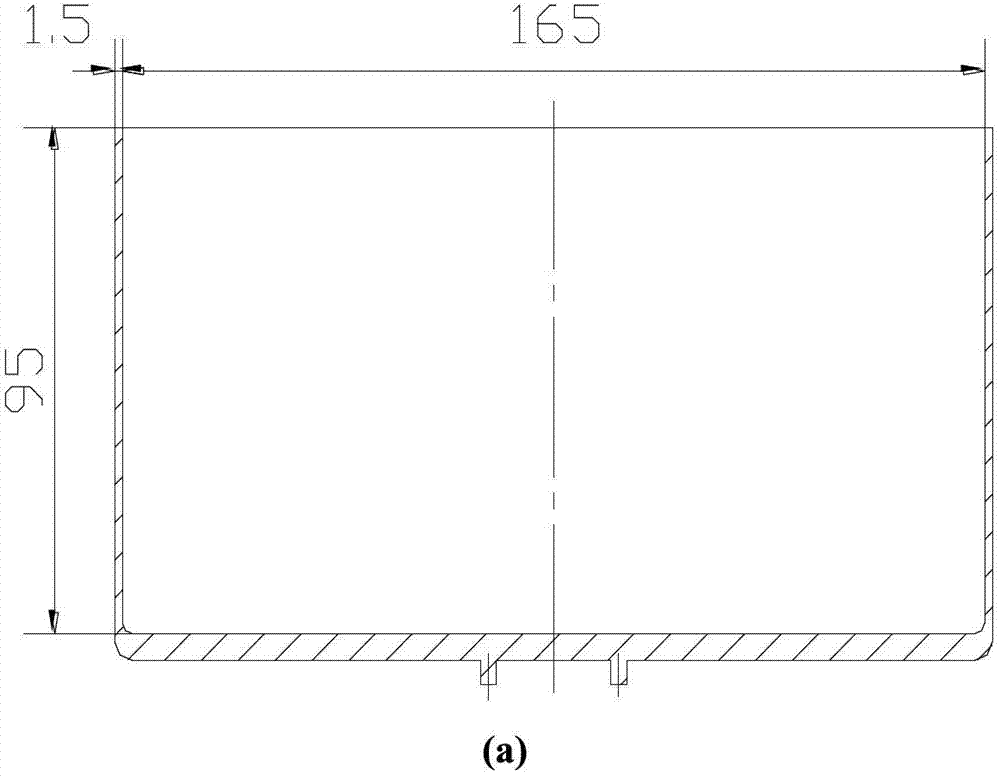

[0030] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to figure 2 The part diagram of the rectangular box-shaped part (with convex column) that needs to be formed is shown, and the size of the rectangular blank is determined as: 167.9mm×43.9mm×13.9mm;

[0031] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0032] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

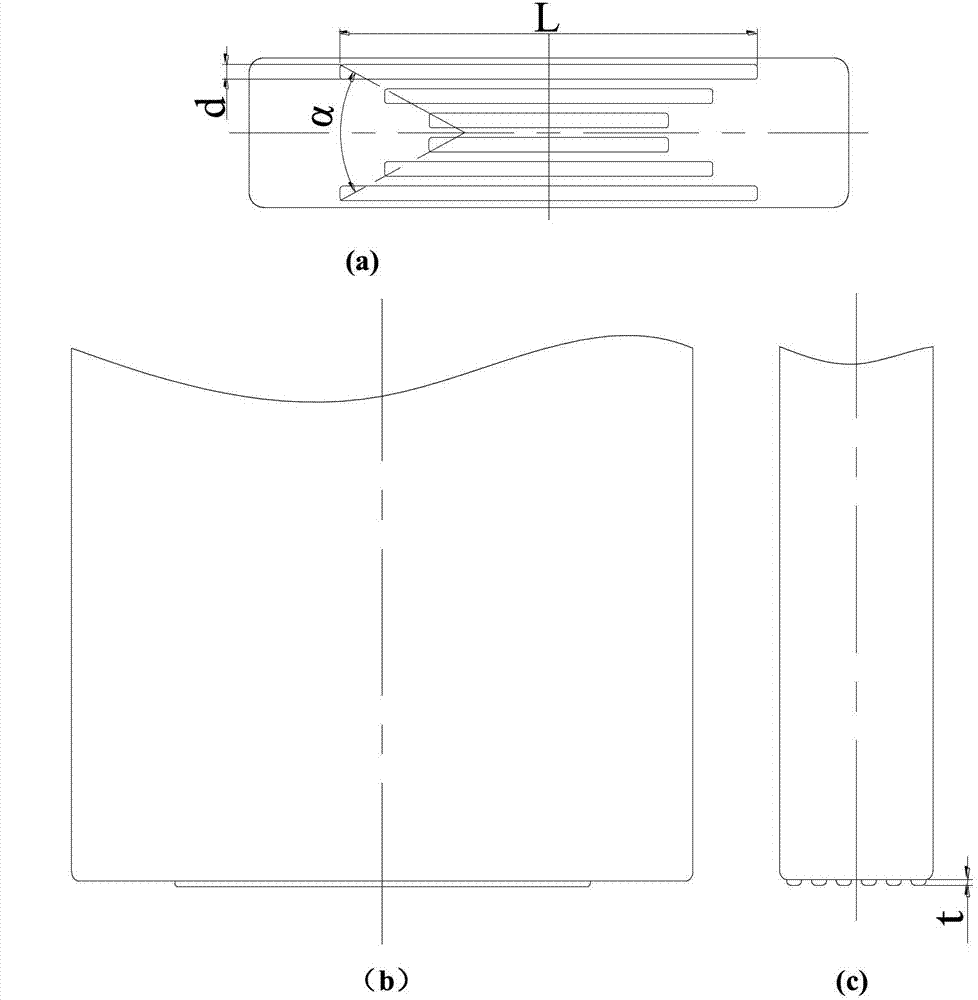

[0033] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the length of the longest damping rib L=90.0mm, the angle α=60°, the width d=3.7mm, and the thickness t=1.0mm.

[0034] The fifth step, according to the height ...

Embodiment 2

[0037] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to figure 2 The part diagram of the rectangular box-shaped part (with convex column) that needs to be formed is shown, and the size of the rectangular blank is determined as: 167.9mm×43.9mm×14.7mm

[0038] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0039] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

[0040] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the longest damping rib length L=110.0mm, angle α=100°, width d=2.2mm, thickness t=0.8mm.

[0041] The fifth step, according to the height of the box-shaped piec...

Embodiment 3

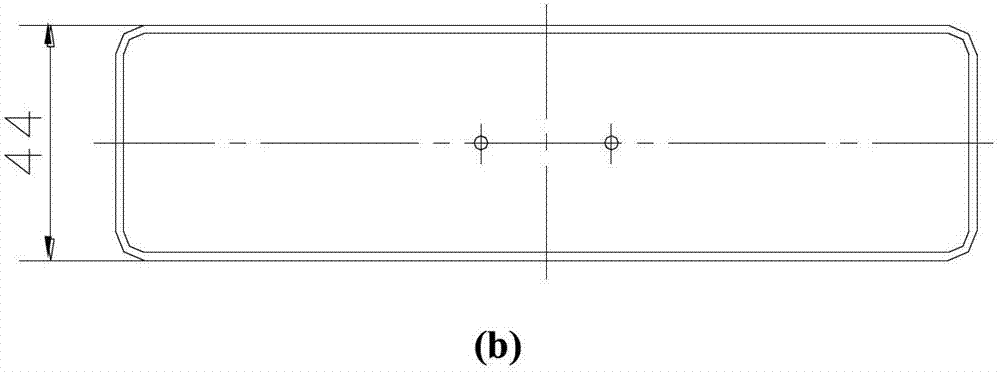

[0044] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to image 3 The part diagram of the rectangular box-shaped part (without convex column) shown in the figure, the size of the rectangular blank is determined as: 167.9mm×43.9mm×14.0mm;

[0045] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0046] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

[0047] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the length of the longest damping rib L=90.0mm, the angle α=60°, the width d=3.7mm, and the thickness t=1.0mm.

[0048] The fifth step, according to the height of the box-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com