Control method for vacuum pollution of moving part and cable in optical system

A technology for moving parts and optical systems, applied in chemical instruments and methods, cleaning methods and utensils, and dust removal, etc., can solve the problems of organic pollutant release, long molecular free path, saturated vapor pressure, etc., to reduce the overall cost, Guaranteed to work properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

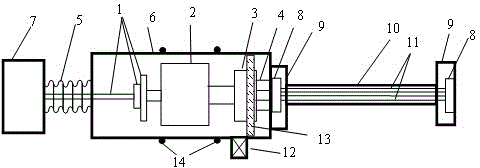

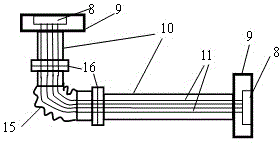

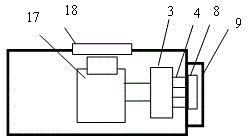

[0027] The device of the present invention is composed of the moving part 1 of the transmission mechanism, the motor 2, the control circuit board 3, the cable 4, the first bellows 5, the transmission mechanism cavity 6, the controlled motion carrier 7, the cable joint 8, the sealing cover 9, the wire Cable outer casing 10, cable 11, vacuum valve 12 and other components.

[0028] Parts and materials that contain lubricants, plasticizers, organic polymer materials, such as motors, transmission mechanisms, control circuit boards, cables, cameras, and light sources, that generate volatile organic pollutants and particle pollutants under vacuum and laser light conditions , by adopting a vacuum sealing method, these components and materials are sealed in the cavity of the transmission mechanism, and the movement of the bellows connected to the cavity is controlled by the transmission mechanism, thereby driving the controlled motion carrier 7 .

[0029] The connection between moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com