Method and arrangement for feeding fuel into a circulating fluidized bed boiler

A fuel supply and fuel flow technology, applied in fluidized bed combustion equipment, combustion methods, combustion equipment, etc., can solve problems such as insufficient combustible fuel, high temperature in the upper part of the combustion chamber, boiler discharge and load change rate problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

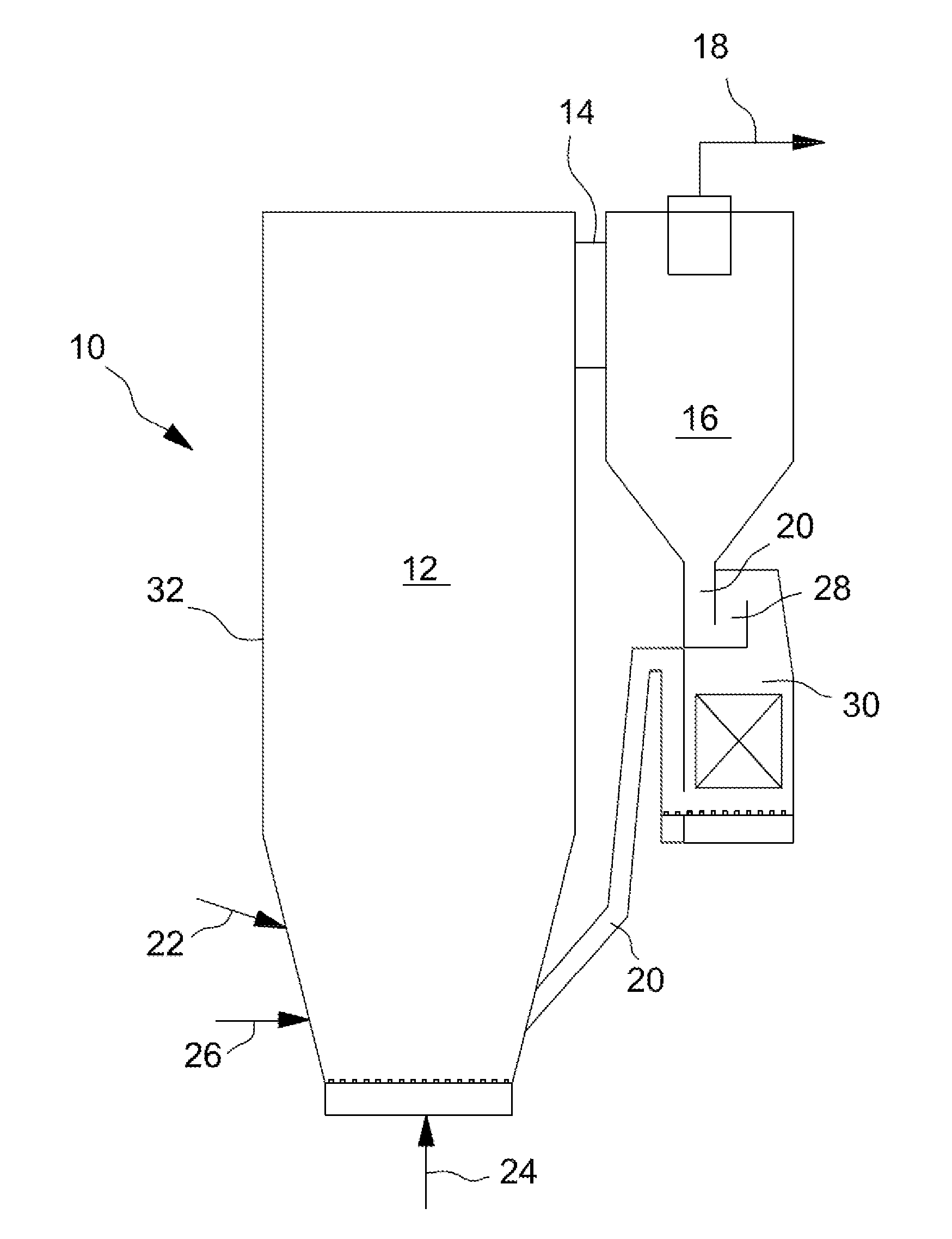

[0041]Fig. 1 schematically shows a prior art circulating fluidized bed boiler. The boiler 10 comprises a combustion chamber 12 with a substantially vertical wall 32, at the upper end of said combustion chamber 12 thus a discharge channel 14 for feeding flue gases and suspended solids into a solids separator 16, arranged at the The upper end of the solid separator 16 so that the passage 18 for discharging the purified exhaust gas from the solid separator 16 is used to return at least a part of the separated solids to the lower part of the combustion chamber 12 in the solid separation The recirculation duct 20 at the lower end of the vessel 16, the fuel supply device 22 arranged at the side wall 32 of the combustion chamber, and the devices 24 and 24 respectively arranged at the lower part of the combustion chamber 12 for introducing main and auxiliary air 26. The fuel supply means may include screw feeders, drop legs, pneumatic feeders, just to name a few alternatives. Primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com