Asphalt mixture anti-stripping agent and preparation method and application thereof

A technology of asphalt mixture and anti-stripping agent, which is applied in the field of modified asphalt, can solve the problems of insufficient use stability, large amount of anti-stripping materials, and many use restrictions, so as to achieve good economy and comprehensive anti-stripping performance, and improve Water stable performance, easy to use and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

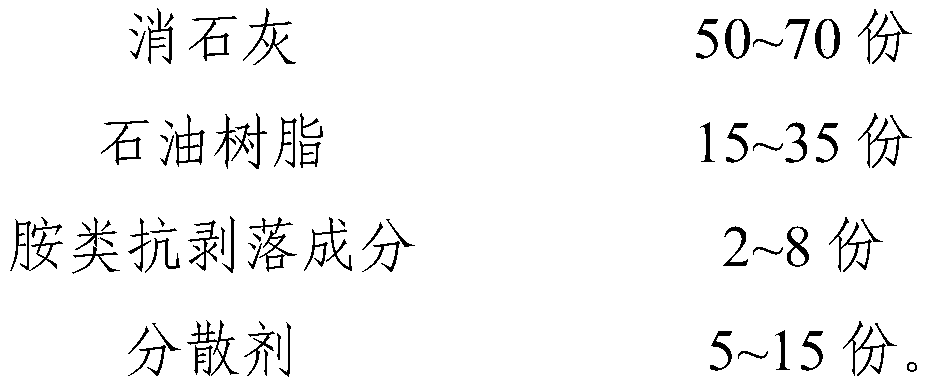

[0041] This embodiment provides an asphalt mixture anti-stripping agent, comprising the following components by weight:

[0042]

[0043] The preparation method of described asphalt mixture anti-stripping agent comprises the steps:

[0044] (1) Mix slaked lime, fatty amide imidazoline, and liquid paraffin with an SDF1100W laboratory frequency conversion disperser (stir slowly first, then gradually increase the speed, and keep it at 1000r / min, and stir for 5min after the speed is stable), to obtain a mixture; wherein, Described slaked lime passes through 0.075mm sieve hole in advance;

[0045] (2) Mix petroleum resin into the mixture, mix for 10 minutes at 1000r / min, 115-125°C, and then extrude and granulate through a screw extruder (SJ4525 small pvc plastic extruder) to obtain mixed granules ;

[0046] (3) Grinding the mixed particles to a fineness of 20-100 meshes.

Embodiment 2

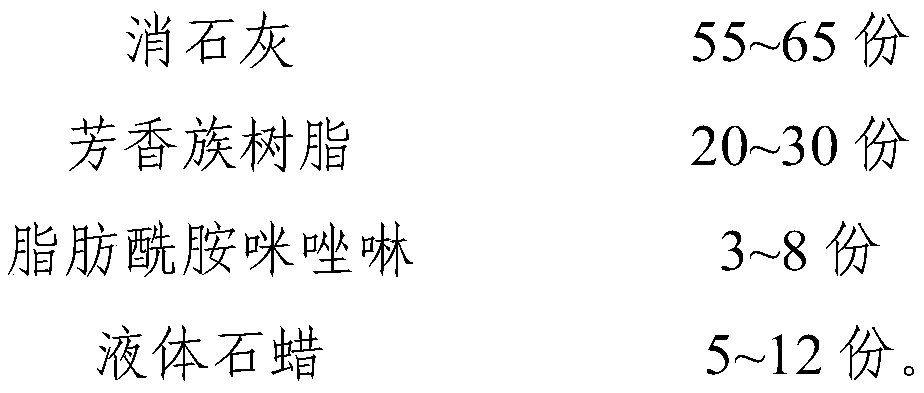

[0048] This embodiment provides an asphalt mixture anti-stripping agent, comprising the following components by weight:

[0049]

[0050]

[0051] The preparation method of the anti-stripping agent for asphalt mixture is the same as in Example 1.

Embodiment 3

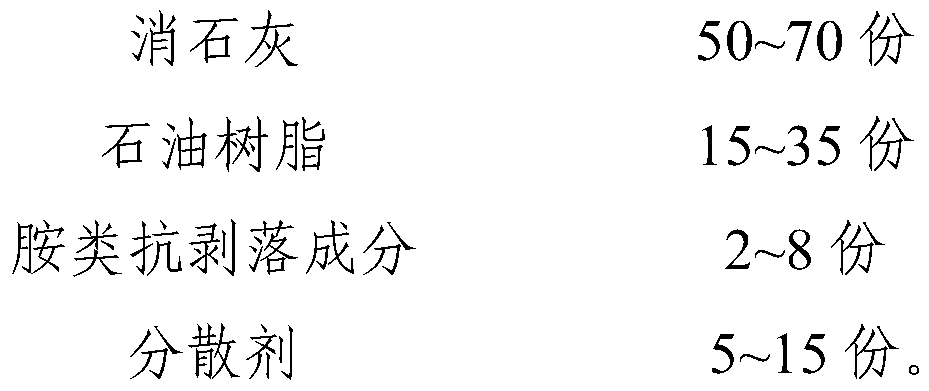

[0053] This embodiment provides an asphalt mixture anti-stripping agent, comprising the following components by weight:

[0054]

[0055] The preparation method of the anti-stripping agent for asphalt mixture is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com