On-line system for automatically monitoring oil state of steam turbine oil in use

A technology for automatic monitoring of steam turbine oil, applied in signal transmission systems, electrical signal transmission systems, analysis materials, etc., can solve the problems of lagging measurement results, high cost, and failure to achieve online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

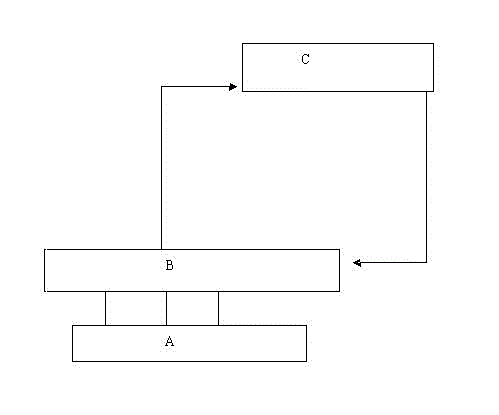

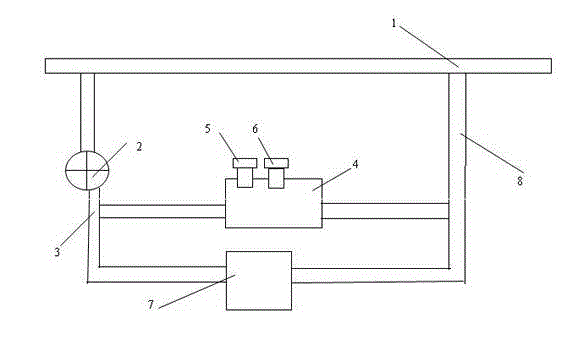

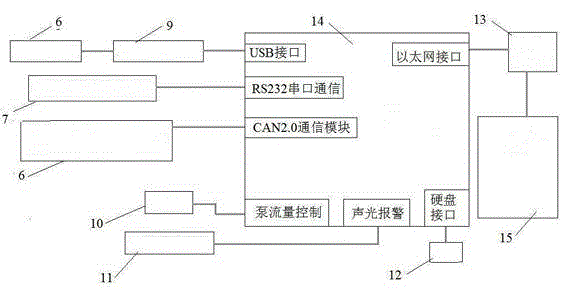

[0025] The design idea of this system is that the system can monitor the viscosity, water content and particle pollution level changes of the turbine oil online in real time. When the viscosity index, water content index or particle pollution index exceeds the set average threshold or peak threshold In time, an audible and visual alarm will be issued in time to remind the on-site staff to take measures for the steam turbine lubricating oil system to prevent the steam turbine from malfunctioning due to changes in the characteristics of the steam turbine lubricating oil.

[0026] Advantage analysis of this system: It can monitor the conventional physical and chemical indicators of the oil in real time during the production process, and record and analyze the change process of the oil through the trend change of the data. All the oil monitoring items are collected by the collector, and the digital signal is transmitted through the communication cable, and there is no other loss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com