High temperature-distributed load thermal strength test device for plane structure of high-speed missile aerobat

A technology of planar structure and distributed load, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficult simulation of distributed load, rubber body rupture, limited temperature resistance, etc., and achieve important military engineering application value and device The structure is simple and the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

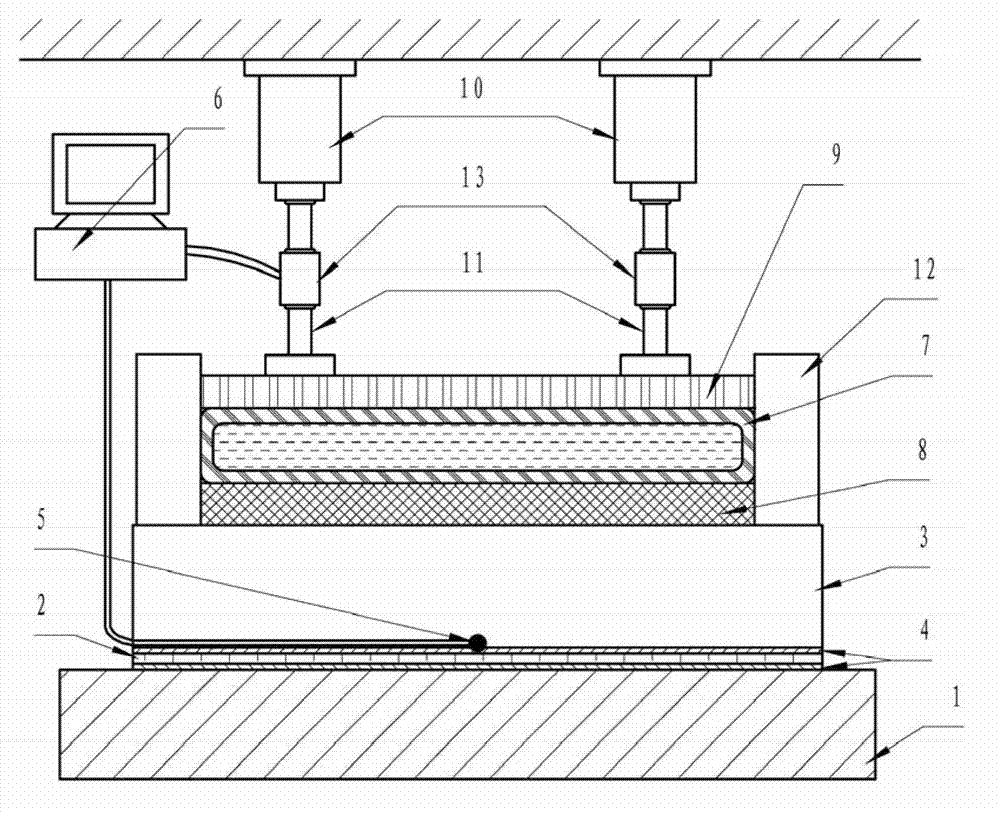

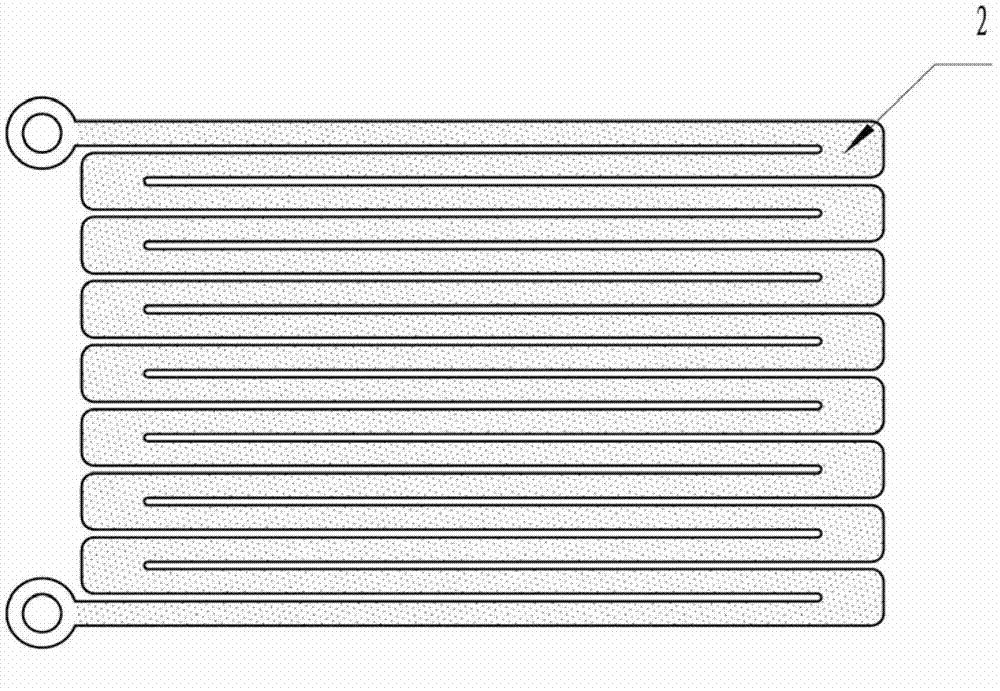

[0021] Such as figure 1 and figure 2 As shown, the present invention consists of a ceramic base 1, a plane high-temperature heating body 2, a high-speed missile plane test piece 3, a high-temperature insulating thin layer 4, a temperature-measuring thermocouple 5, a computer 6, a water bag loader 7, and a flexible heat-insulating material 8. It consists of a steel force plate 9, a hydraulic actuator 10, a loading link 11, a ceramic frame 12, and a force sensor 13. A plane high-temperature heating sheet 2 is placed on the ceramic base 1, and a high-speed missile plane test piece 3 is pressed on the plane high-temperature heating body 2. The top and bottom of the plane high-temperature heating body 2 are covered with a high-temperature-resistant insulating thin layer 4, and the temperature measurement thermoelectric The couple 5 is placed on the lower side of the high-speed missile plane test piece 3, and the temperature measuring thermocouple 5 is connected with the computer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com