Tube bundle for radiant heat transfer by extracting phase transformation heat of compressed steam

A technology of radiation heat transfer and phase change heat, which is applied in heating devices and heating fields, can solve the problems of high pipeline cost, difficult to guarantee construction quality, and increased cost, so as to reduce the difficulty of on-site construction, save the installation workload, and ensure the The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

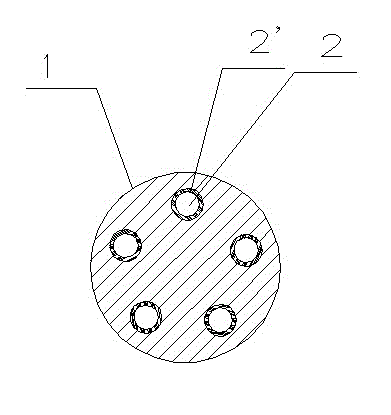

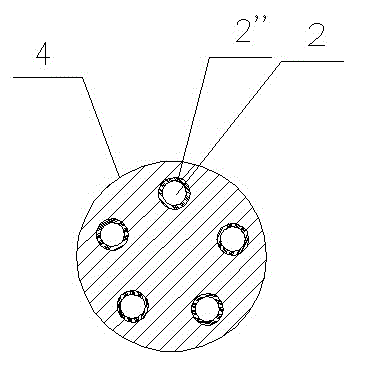

[0021] Embodiment 1: as figure 1 , 2 , 3, and 9, the present embodiment is used to extract the phase change heat of compressed steam for radiation heat transfer. The liquid head 4; the gas distribution head 1 has an air inlet joint 5 installed with it and communicated with the inner cavity, and the liquid return head 4 has a liquid return joint 3 installed with it and communicated with the inner cavity.

[0022] The structure of the gas distribution head is the same as that of the liquid return head. There are through-holes 2' having the same number as the number of capillary tubes 2 in the distributor head 1. The inner diameters of the through-holes 2' correspond to the outer diameters of each capillary tube 2, and one end of each capillary tube 2 is fixed on the In the through hole 2' in the gas distribution head 1. There are also through-holes 2" in the liquid return head 4 having the same number as the capillary tubes 2, and the inner diameters of the through-holes 2" a...

Embodiment 2

[0025] Embodiment 2: as Figure 4 As shown, the structure of this embodiment is the same as that of Embodiment 1, except that the gas distribution head 1 and the liquid return head 4 are tubes with a length less than or equal to 30 cm, and the inside of the tubes is a stepped hole. One end of each capillary 2 is fixed in the trachea 1 . The other end of each capillary 2 is fixed in the liquid return pipe 4 . The capillaries 2 are evenly distributed in the gas distribution pipe 1 and the liquid return pipe 4 . The ends of the gas distribution pipe 1 and the liquid return pipe 4 all have a bottom plate 6 that fixes the capillary and prevents air leakage.

[0026] Other structures are the same as in Embodiment 1.

Embodiment 3

[0027] Embodiment 3: as Figure 5 , 6 As shown, a group of tube bundles in this embodiment includes 4 capillaries 2, a gas distribution head 1, and a liquid return head 4; the gas distribution head 1 has an air inlet joint 5 installed together with it and communicated with the inner cavity , the liquid return head 4 has a liquid return joint 3 installed together with it and communicated with the inner cavity. The outer diameter of the upper part 1a of the gas distribution head 1 is smaller than the outer diameter of the lower part 1b, and there are 4 through holes 2' communicating with the inner hole of the upper part 1a of the gas distribution head 1 on the bottom surface of the lower part 1b, and each through hole 2' is fixed with a root capillary; in order to facilitate the positioning of the capillary, the through hole 2' can also be a step hole; the inner diameter of the contact part with the air inlet joint 5 is closely matched with the air inlet joint 5, and the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com