Coal-water slurry boiler steam supply engineering system provided with self-adapting three-control function

A separate control and self-adaptive technology, applied in control systems, steam generation, lighting and heating equipment, etc., can solve problems such as multi-quality, high-fluctuation steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

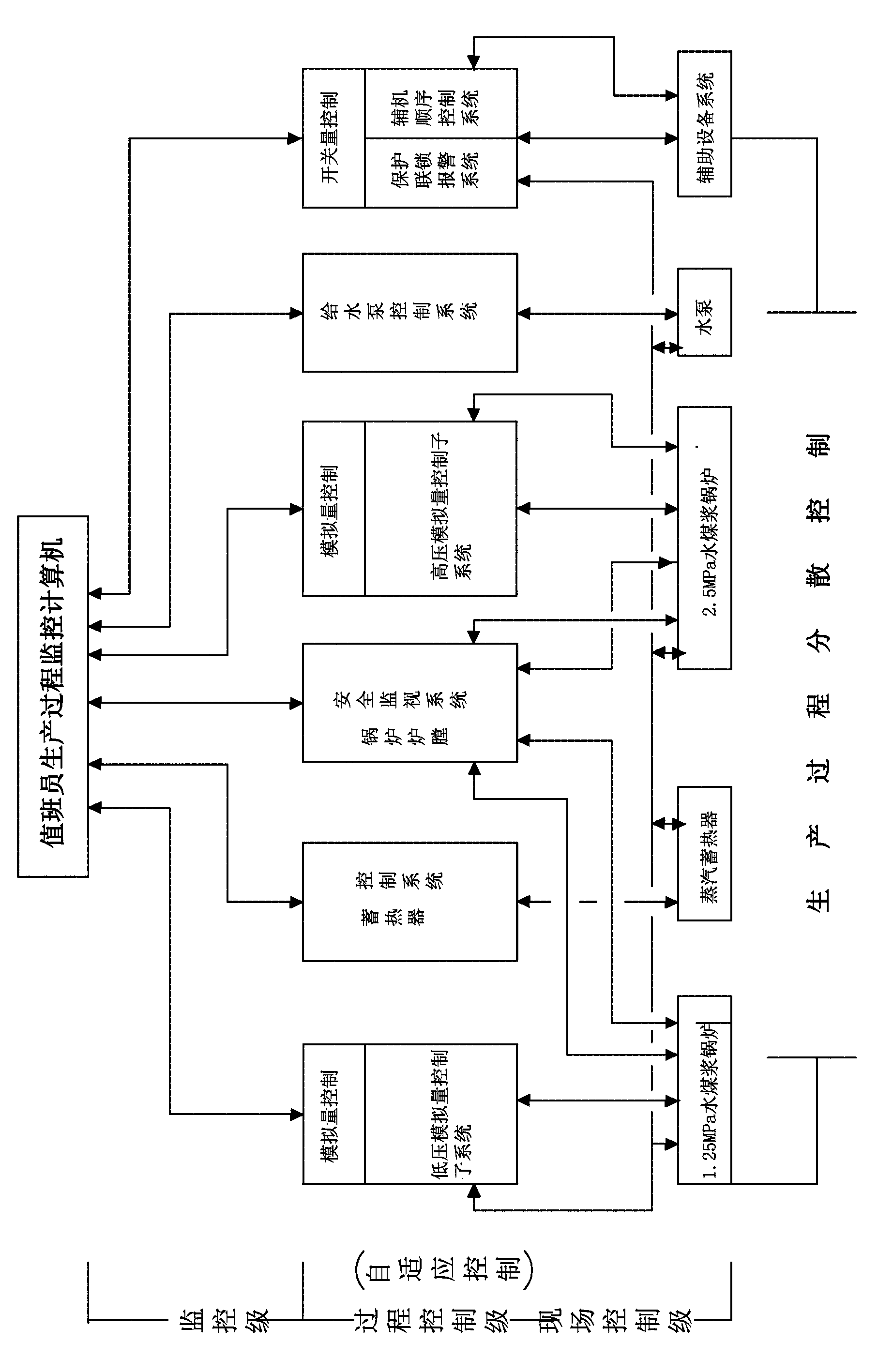

[0027] Such as figure 1 The shown coal-water slurry boiler steam supply engineering system with adaptive three-point control function includes a monitoring level system, a process control level system, and a field control level system; the monitoring level system is produced by a watchman The process monitoring computer is composed; the process control level system is composed of an analog control function block respectively connected with the production process monitoring computer of the attendant (the analog control function block consists of a high-voltage analog control subsystem and a low-voltage analog control subsystem) control subsystem), a heat accumulator control system, a boiler furnace safety monitoring system, a feed water pump control system and a switch control function block; the field control level system consists of high and low pressure coal water slurry boilers, Composed of steam accumulator, water pump and auxiliary equipment system connected to the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com