Radial type shield body torsionproof device

A articulated, anti-twist technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as the deformation of the shield tail connection ring and the shield tail 5 out of round, and achieve the effect of ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

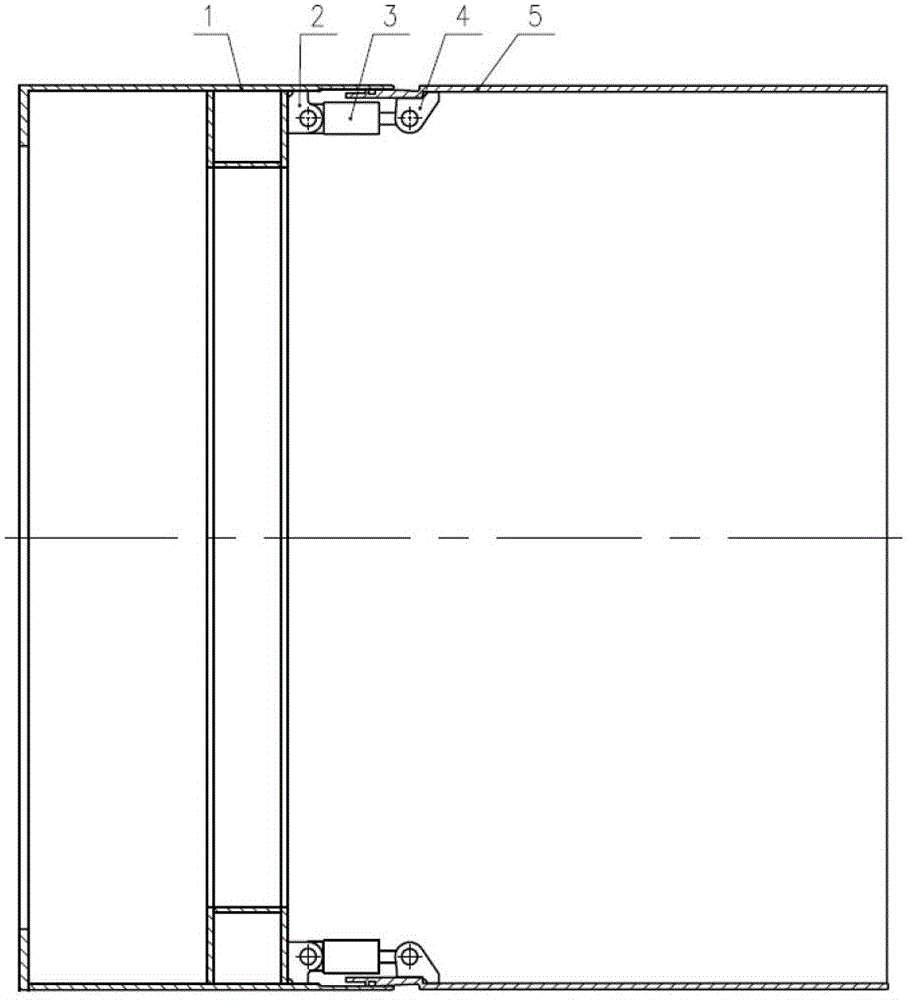

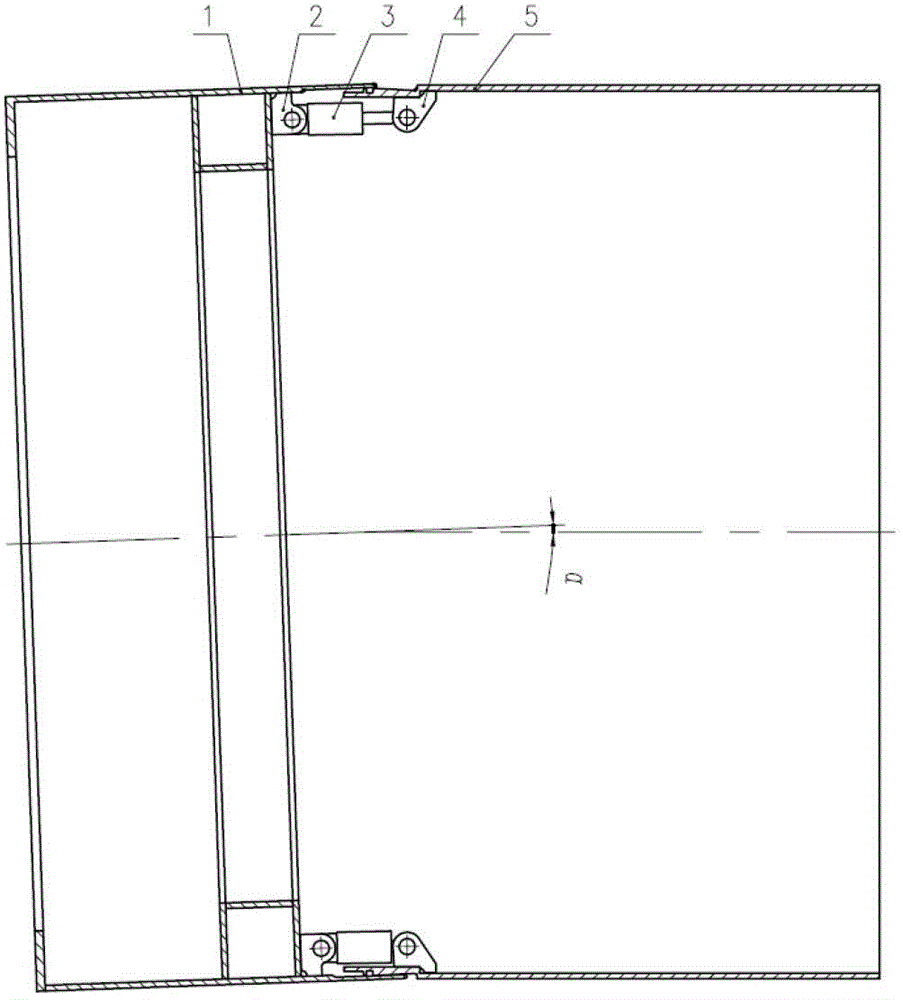

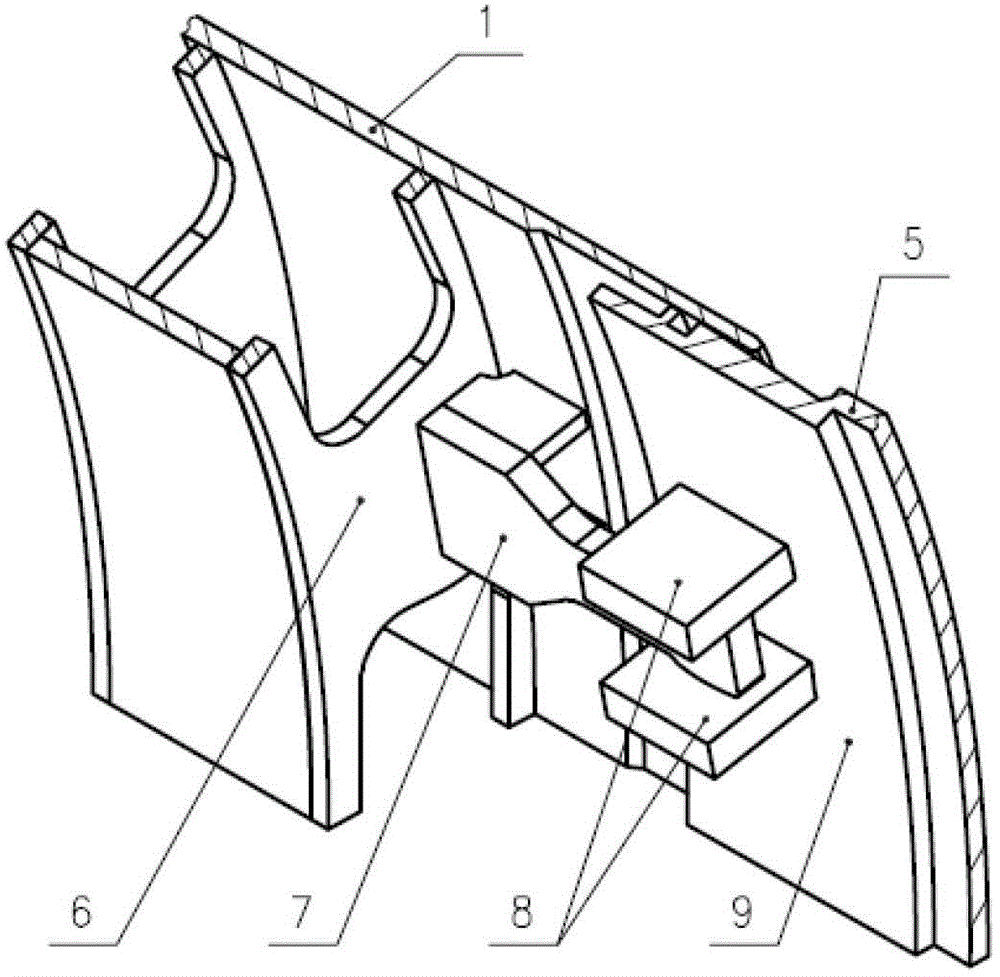

[0023] The technical solution of the present invention will be described below in conjunction with the accompanying drawings.

[0024] Figure 4 Shown is an anti-twist device 50 according to the invention, which is intended to be installed between the center shield 1 and the shield tail 5 of the articulated shield body to prevent mutual rotation between the center shield 1 and the shield tail 5 .

[0025] As shown in the figure, the center shield 1 of the articulated shield body includes a center shield rear support ring plate 6 and a center shield support ring 10 . A central shield hinge seat 2 is arranged on the central shield rear supporting ring plate 6 . The shield tail 5 includes a shield tail connecting ring 9 and a shield tail hinge seat 4 installed on the shield tail connecting ring 9 . A hinged oil cylinder 3 is installed between the hinged seat 2 of the central shield and the hinged seat 4 of the shield tail, so that the central shield 1 and the shield tail 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com