Dragging device for movable component on machine tool guide rail

A technology of moving parts and dragging devices, which is applied in the direction of auxiliary devices, metal processing machinery parts, toolholder accessories, etc., can solve the problems of increasing costs and increasing auxiliary processing time, etc., and achieves large dragging force and smooth dragging process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

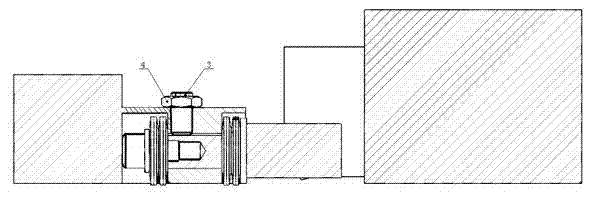

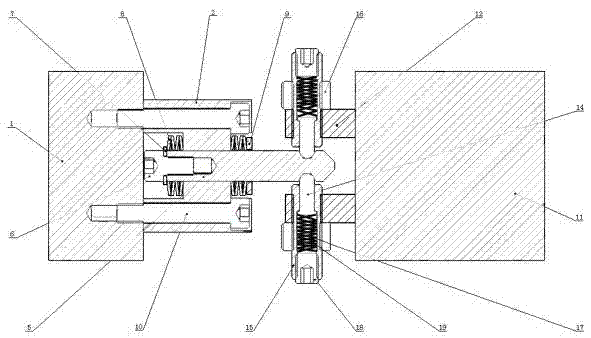

[0021] Embodiment 1: as figure 1 , figure 2 As shown, a dragging device for moving parts on a machine tool guide rail includes a bed saddle 1 and a pull rod 5 arranged on the bed, and a pull rod support 2 is fixedly connected to the bed saddle 1, and the pull rod 5 Threaded on the tie rod support 2, a tie rod buffer device is provided at one end of the tie rod 5 in contact with the tie rod support 2, and a tie rod fixing device is provided on the tie rod support 2 above the tie rod 5; There are two clamping devices on the moving part facing each other, and the ball studs of the two clamping devices are respectively inserted into the grooves at one end of the pull rod. The pull rod buffer device includes a first spring 8 , and the first spring 8 is fixed on the pull rod 5 through a first screw 6 , a first washer 7 , and a second washer 9 . The first spring 8 is a belleville spring. The clamping device includes a ball stud 14, the front end of the ball stud 14 is inserted in...

specific Embodiment approach

[0023] The saddle 1 of the horizontal lathe is provided with an independent driving source, which can move longitudinally along the guide rail of the bed, and can be precisely positioned at any position on the bed. When the tailstock 11 needs to be moved, the saddle 1 drives the pull rod 5 fixed on the support 2 to move towards the tailstock 11. Since the tailstock 11 is fixed on the bed through the pressure plate, the pre-tightening force of the spring 17 and the spring 19 is not enough. The tailstock is moved, and now the two ball studs are inserted into the grooves of the pull rod 5 (the pretightening force of the ball stud 14 can be adjusted by the set screw 18). Then loosen the pressure plate screw of the tailstock 11, the pre-tightening force of the spring 17 and spring 19 is greater than the frictional force of the tailstock, the bed saddle 1 drags the tailstock 11 to move to the position required for processing under the action of the driving source, and finally tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com