Elastic microporous film trawl net bag

An elastic film and mesh bag technology, applied in the field of marine fishery, can solve the problems of small mesh size and high water permeability, and achieve the effects of enhanced water filtration, improved service life, and reduced drag force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

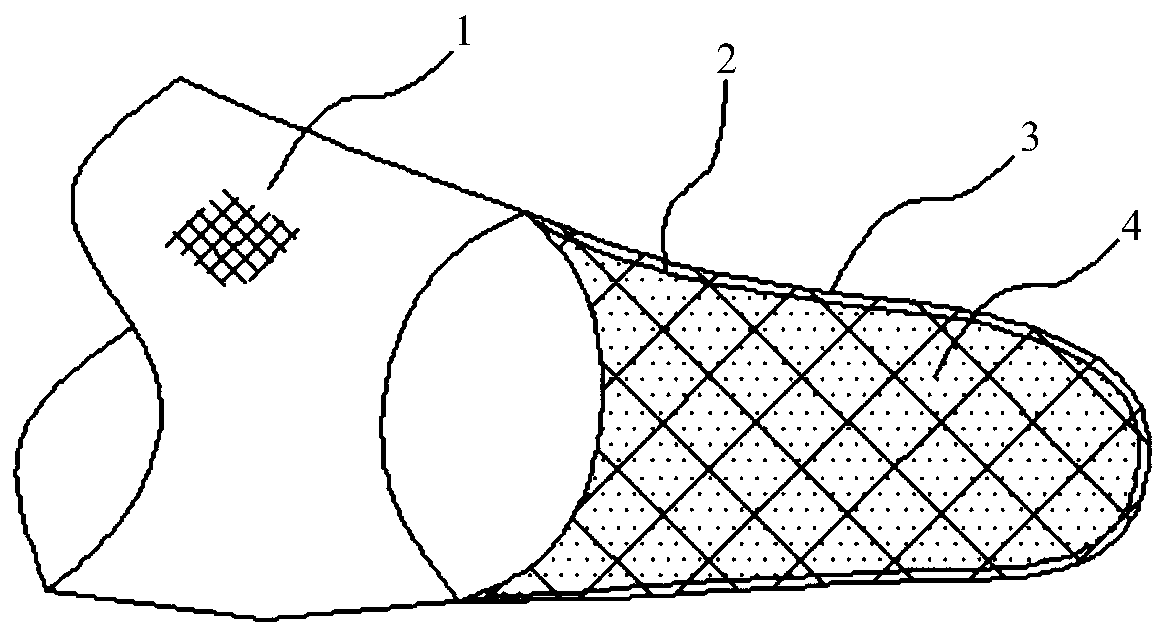

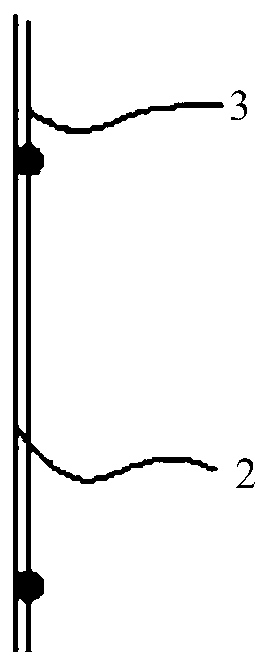

[0022] see figure 1 As shown, the present invention discloses a kind of elastic small-hole film trawl mesh bag, and described trawl mesh bag is made up of inner mesh bag 2 and outer mesh bag 3, and size and shape are consistent, and inner mesh bag 2 is on the inner side, and outer mesh bag 3. On the outside, the openings are woven together and connected with the opening at the tail end of the net clothing 1 of the trawl net, and are towed by the fishing boat.

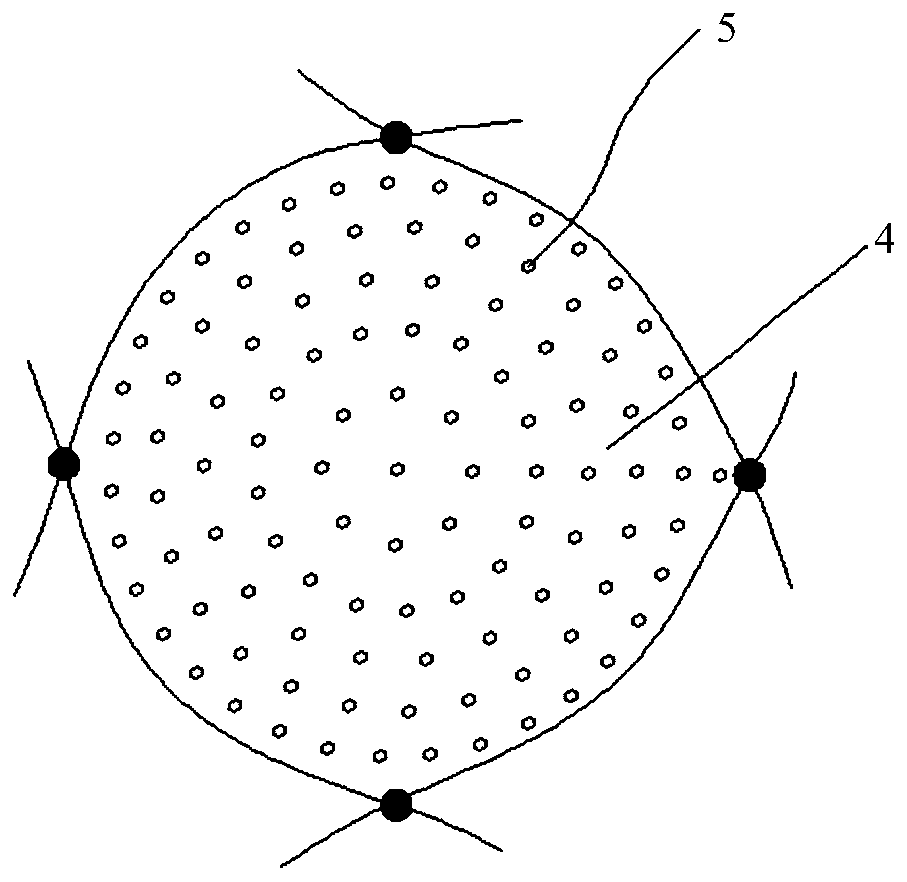

[0023] see figure 1 , figure 2 and image 3 As shown, the inner mesh bag 2 is a kind of elastic film material, has certain ductility, and the surface is evenly distributed with small holes 5. In the initial state of operation, the elastic film material of the inner mesh bag 2 is in a natural state, and the small holes 5 The water filterability is low, and the water body in the mesh sac is filled, so that the mesh sac can fully expand.

[0024] see Figure 4 and Figure 5 As shown, with the increase of the draggin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com