Glass plane materiel connecting device for curtain wall arborescent supporting vertical frame

A connecting device and glass surface technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as the installation requirements of glass surface material components that cannot meet the tree-shaped support mullions of the curtain wall, etc., to improve the external vision effect and facilitate on-site construction. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

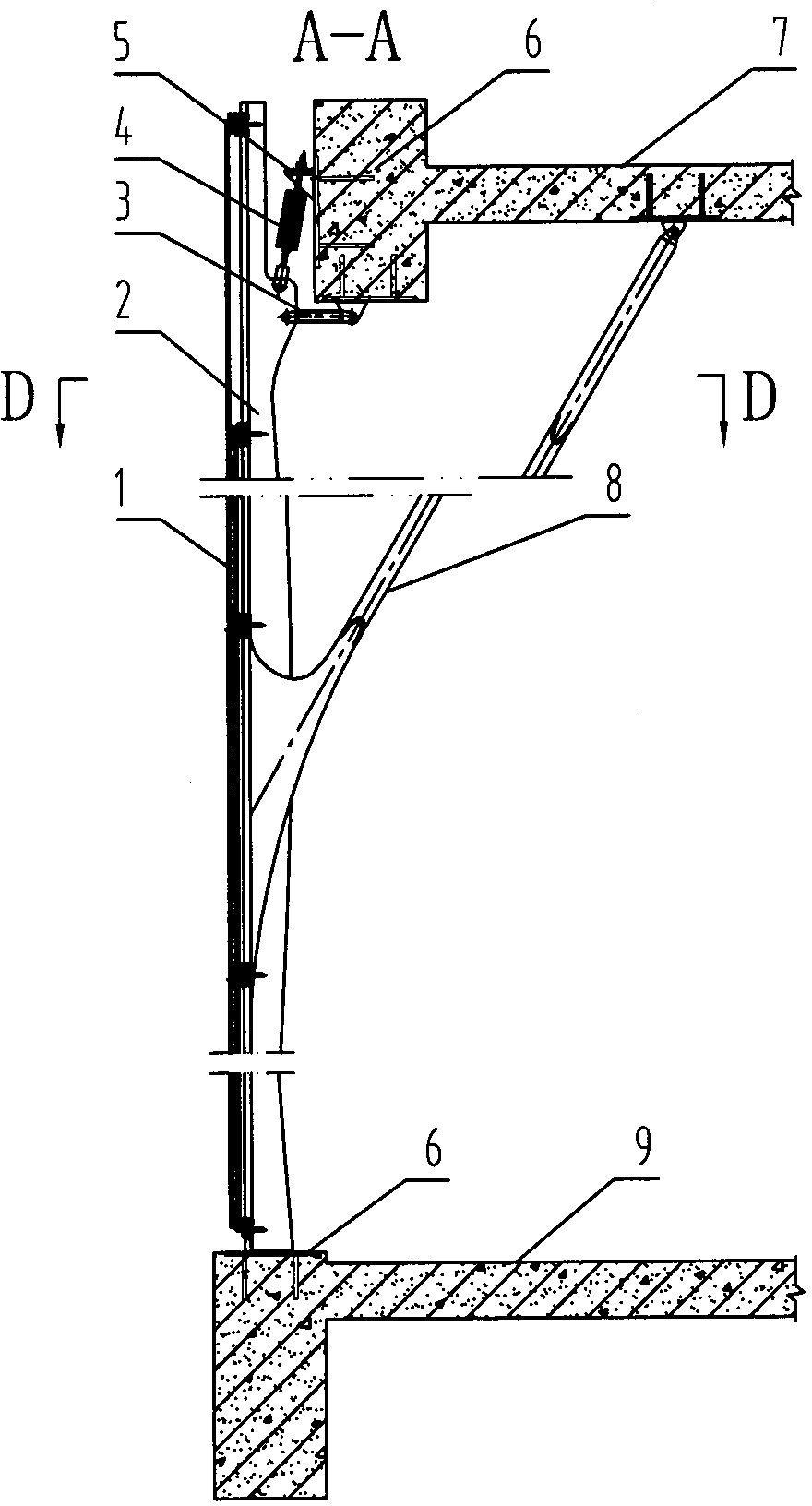

[0016] according to Figure 1-5 The specific structure of the present invention will be described in detail. The glass surface material connecting device for the tree-shaped support mullion of the curtain wall includes a connecting assembly for assembling the glass surface material assembly 1 on the variable-section main mullion 2 and the T-shaped horizontal frame 16 of the tree-shaped support mullion of the curtain wall. Among them, the curtain wall tree support mullion (such as figure 2 As shown) a tree-like support structure is formed by a variable-section main mullion 2 and two variable-section secondary mullions 8 symmetrically supported in the middle of the variable-section main mullion 2 . The variable cross-section main mullion 2 is a T-shaped frame welded by the equal cross-section profile as the top plate and the variable cross-section profile as the web plate, and the variable cross-section secondary mullion 8 is welded by the variable cross-section profile as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com