Blast furnace tapping method for reducing circulating flow of molten iron in hearth

A blast furnace tapping and hearth technology, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve the problem of inability to judge the slag iron capacity and liquid level in the hearth, the speed of the liquid surface in the hearth dropping too fast, and increasing the hearth. Carbon brick erosion and other problems, to avoid the flow of molten iron, reduce the operating burden in front of the furnace, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

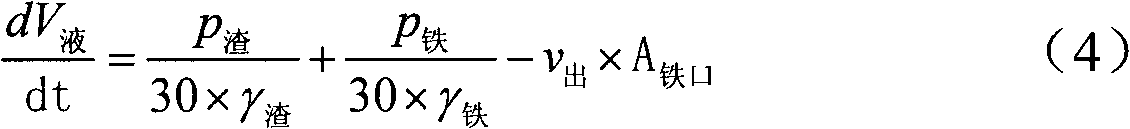

Method used

Image

Examples

Embodiment 1

[0052] In a volume of 2580m 3 For blast furnace application, the specific steps are as follows:

[0053] 1) According to the blast furnace smelting conditions and raw material conditions, the comprehensive furnace charge compression rate is 14%, and the actual consumption of the comprehensive furnace charge volume on the day is 9000m3 3 , the calculated smelting period T is 480min;

[0054] 2) At the end of 10:30 tapping, after the mud gun has blocked the tap hole and the model receives the signal, it immediately reads the clock t1 in the computer, t1=10:30, and determines that the time period from 10:30 to 11:00 is tapping Intervals;

[0055] 3) Read from the feeding data table in the database, within the time period from t1-450 to t1-480, that is, the data of raw materials, fuel consumption and chemical composition within the time period from 3:00 to 3:30; Read the pulverized coal injection volume and chemical composition data in the time period from t1-270 to t1-240, tha...

Embodiment 2

[0059] In a volume of 3200m 3 For blast furnace application, the specific steps are as follows:

[0060] 1) According to the blast furnace smelting conditions and raw material conditions, the comprehensive charge compression rate is determined to be 15%, and the actual consumption of the comprehensive charge volume on the day is 10630m 3 , the calculated smelting period is 510min;

[0061] 2) At the end of 10:30 tapping, after the mud gun has blocked the tap hole and the model receives the signal, it immediately reads the clock t1 in the computer, t1=10:30, and determines that the time period from 10:30 to 11:00 is tapping Intervals;

[0062] 3) Read from the feeding data table in the database, raw material, fuel consumption and chemical composition data in the time period from 2:30 to 3:00; read from the pulverized coal injection data table in the database from 6:00 to 6 : Coal powder injection volume and chemical composition data in the 30 time period, calculate the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com