Two-stage fluidized bed coal bed gas non-catalytic deoxidation technology

A first fluidized bed, coalbed methane technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of low methane concentration and high methane loss rate, achieve high deoxygenation efficiency, high utilization rate, and improve mass transfer. The effect of thermal coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is further described below:

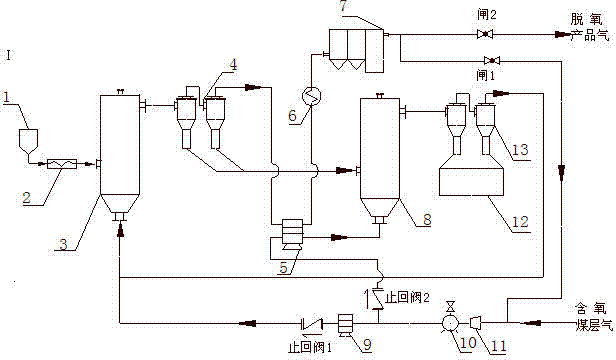

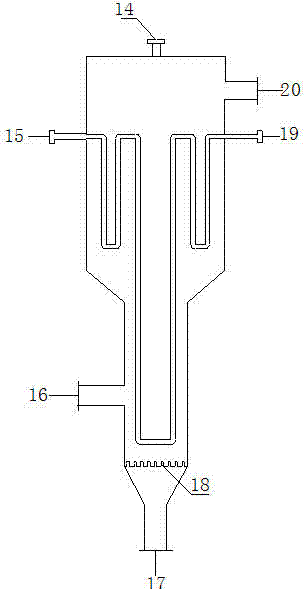

[0028] like figure 1 Describe, carry out a kind of secondary fluidized bed coalbed methane non-catalytic deoxidation process provided by the present invention, the deoxidizer raw material that adopts is to take semi-coke as an example, the raw material coalbed methane that adopts is the preparation coalbed methane, the mixed raw material gas that adopts is Start the mixed gas of unqualified product gas and raw coalbed methane, and prepare the composition of coalbed methane as follows: (vol%): CH 4 : 25.63; O 2 : 12.67; N 2 : 61.73;, the deoxidizer used is: non-catalytic deoxidizer with particle size <3mm, its deoxidation reaction pressure is: 0.008Mpa, in the first fluidized bed reactor, the feed amount of selected deoxidizer per unit time is 140kg / h, the feed rate of raw coalbed methane and primary product gas per unit time is 1200kg / h, satisfying that the feed mass ratio of raw coalbed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com