Method for preparing aliphatic polyoxalate

A polyoxalate and aliphatic technology, which is applied in the field of preparation of high molecular weight polyoxalate, can solve the problems of high cost, difficulty in improving the molecular weight, etc., and achieve the effects of increasing yield, reducing dependence, and facilitating programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Take 200g of dimethyl oxalate, 136g of ethylene glycol, add 0.03% stannous chloride, 0.2‰ stabilizer polyphosphoric acid, mix well, and add to a 1L multifunctional polyester reactor. Heat the reaction, keep the internal temperature at 150°C, strengthen it at 400kPa, react for 3 hours, and fractionally distill methanol to reach about 95% of the theoretical amount. Start vacuuming, keep at 150°C with an absolute pressure of 40kPa for 1h, at 160°C with an absolute pressure of 15kPa for 1h, and at a temperature of 180°C with an absolute pressure of 100Pa for 3 hours. The material was discharged and vacuum-dried for 12 hours, the yield was 83.45%, and the product was a white solid. Take the above dry product, put it into a 250ml round bottom flask, and react for 40h at 125°C with an absolute pressure below 100Pa. The final product was obtained with a yield of 99.77%.

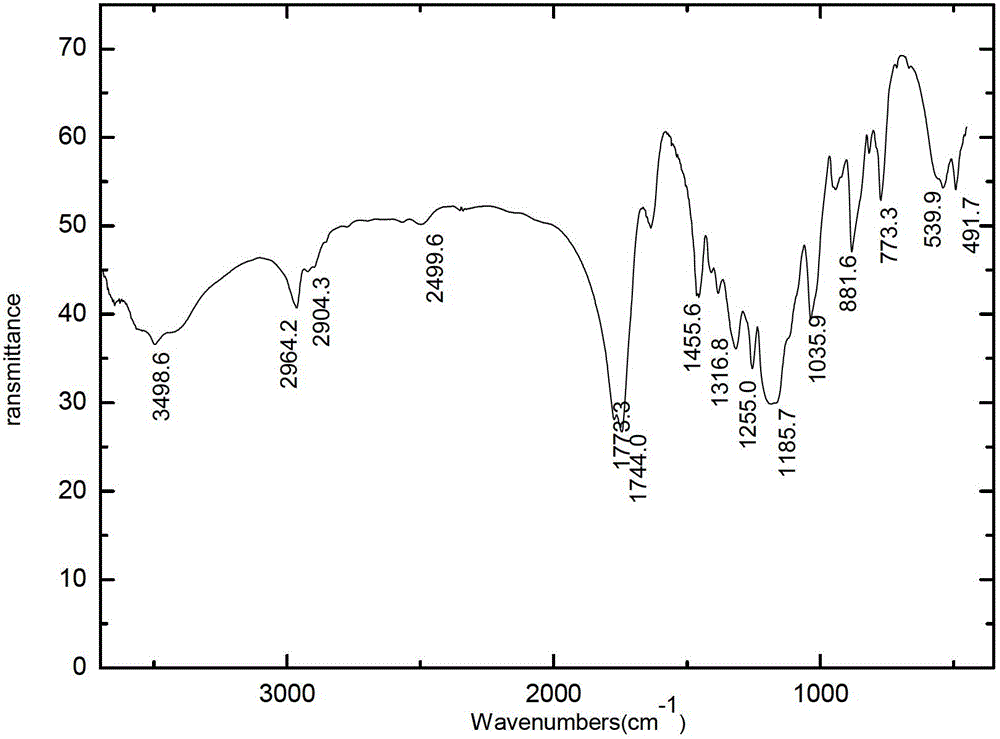

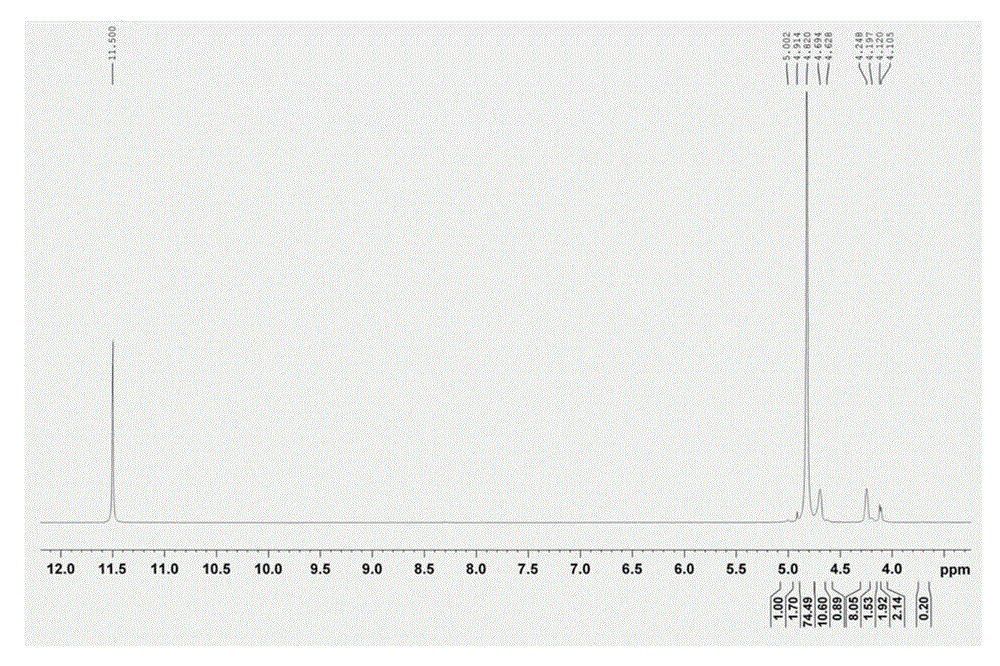

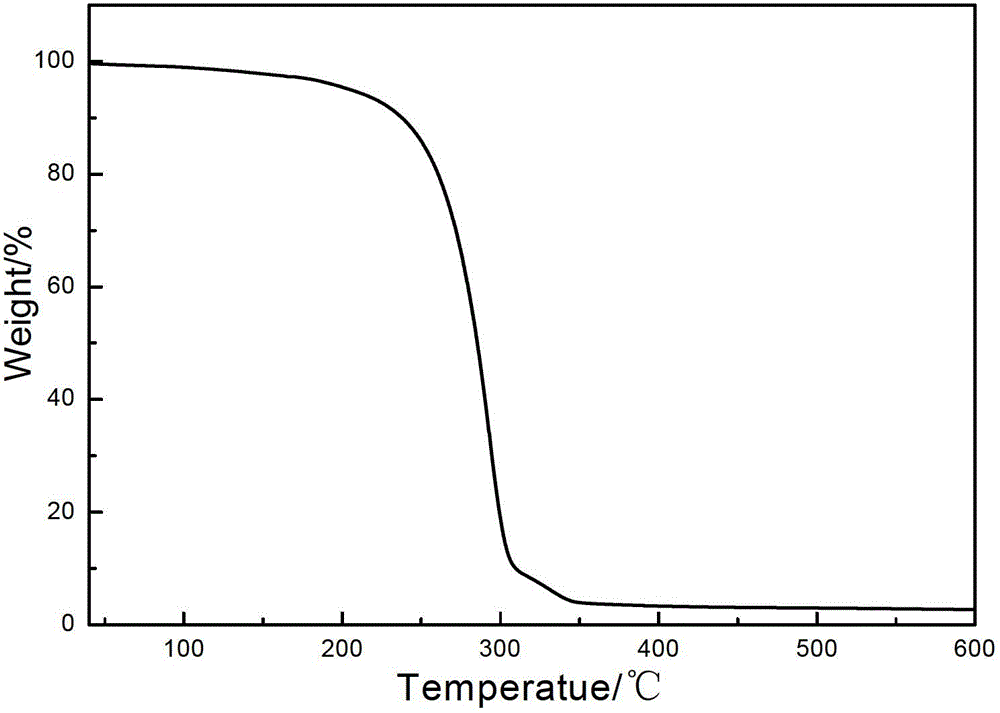

[0060] The infrared spectrogram of the polyethylene oxalate prepared in the present embodiment one. Depe...

Embodiment 2

[0068] Take 200g of dimethyl oxalate and 136g of ethylene glycol, add 0.03% antimony trioxide and 0.2‰ stabilizer polyphosphoric acid, mix well, and add to a 1L multifunctional polyester reactor. Heat the reaction, keep the internal temperature at 180°C, and the pressure at 600kPa, react for 2 hours, and fractionally distill methanol to reach about 95% of the theoretical amount. Start vacuuming, keep at 150°C with an absolute pressure of 40kPa for 1h, at 160°C with an absolute pressure of 15kPa for 1h, and at a temperature of 180°C with an absolute pressure of 100Pa for 3 hours. The material was discharged and vacuum-dried for 12 hours, the yield was 66.32%, and the product was a white solid. Take the above dry product, put it into a 250ml round bottom flask, and react for 55h at 100°C with an absolute pressure below 100Pa. The final product was obtained with a yield of 99.32%.

Embodiment 3

[0070] Take 200g of dimethyl oxalate, 136g of ethylene glycol, add 0.25% zinc acetate, 0.2‰ stabilizer polyphosphoric acid, mix well, and add to a 1L multifunctional polyester reactor. Heat the reaction, keep the internal temperature at 120°C, and the pressure at 200kPa, react for 6 hours, fractionally distill methanol to reach about 95% of the theoretical amount. Start vacuuming, keep at 150°C with a vacuum degree of 40kPa for 1h, at 160°C with an absolute pressure of 20kPa for 1h, and at a temperature of 180°C with an absolute pressure of 100Pa for 3 hours. The material was discharged and vacuum-dried for 12 hours, and the yield was 78.63%. Take the above dry product, put it into a 250ml round bottom flask, and react for 50h at 125°C with an absolute pressure below 100Pa. Just get the final product, the yield is 99.87%, and the product is a white solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com