Ceramsite dual-doped shotcrete for high-temperature tunnel rock surfaces

A technology of shotcrete and concrete, which is applied in the field of concrete, can solve problems such as poor consolidation effect between shotcrete and rock surface, reduced bond strength between concrete and rock surface, and insufficient cement hydration, so as to improve various performances, reduce Effect of small layer segregation and low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Preparation of LC25 ceramsite double-doped fiber shotcrete (wet spray method)

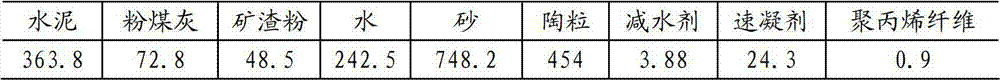

[0016] Application of main raw materials and main proportion parameters of concrete per cubic meter:

[0017] ⑴The total amount of cementitious materials is 485kg (75% cement, 15% fly ash, 10% slag powder);

[0018] ⑵ Ceramsite 454kg (ordinary gravel equal volume replacement);

[0019] (3) Polypropylene fiber 0.9kg;

[0020] ⑷JX-GBNHy2 high-performance polycarboxylate superplasticizer dosage 0.8%;

[0021] ⑸JX-E 3 Liquid accelerator dosage 5%;

[0022] ⑹ sand rate 0.45; water-binder ratio 0.50.

[0023] The specific matching ratio is as follows (unit: kg)

[0024]

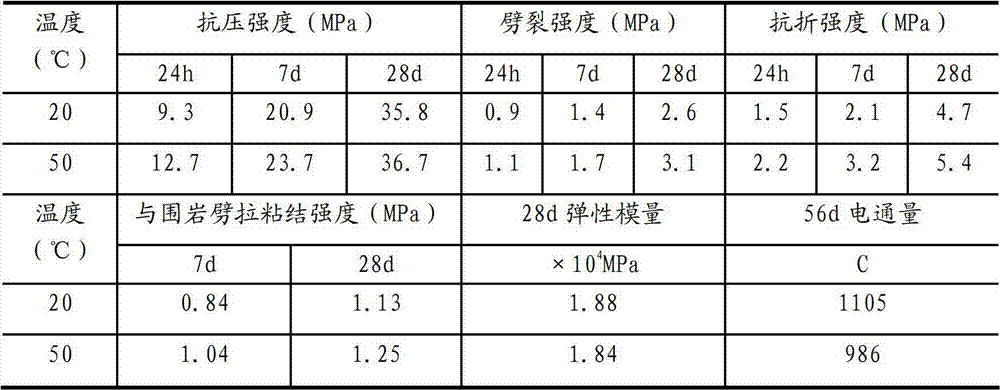

[0025] Technical index test: apparent density 1890kg / m 3 , thermal conductivity 0.47W / (m.K), slump 110mm.

[0026]

Embodiment 2

[0027] Example 2: Preparation of LC30 ceramsite double-doped fiber shotcrete (wet spray method)

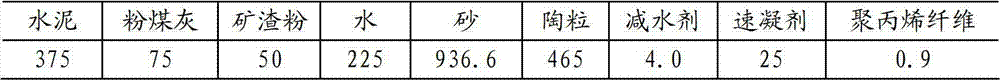

[0028] Application of main raw materials and main proportion parameters of concrete per cubic meter:

[0029] ⑴The total amount of cementitious materials is 500kg (75% cement, 15% fly ash, 10% slag powder);

[0030] ⑵ Ceramsite 465kg (ordinary gravel equal volume replacement);

[0031] (3) Polypropylene fiber 0.9kg;

[0032] ⑷JX-GBNHy2 high-performance polycarboxylate superplasticizer dosage 0.8%;

[0033] ⑸JX-E 3 Liquid accelerator dosage 5%;

[0034] ⑹ sand rate 0.50; water-binder ratio 0.45.

[0035] The specific matching ratio is as follows (unit: kg)

[0036]

[0037] Technical index test: apparent density 1897kg / m 3 , thermal conductivity 0.45W / (m.K), slump 107mm.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com