Method for preparing carbon-material-carrying tin dioxide nanosheet composite material

A technology of tin dioxide and composite materials, applied in tin oxide, carbon compounds, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable environmental protection, high cost, easy agglomeration of tin dioxide particles, etc. Simple, low production cost and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

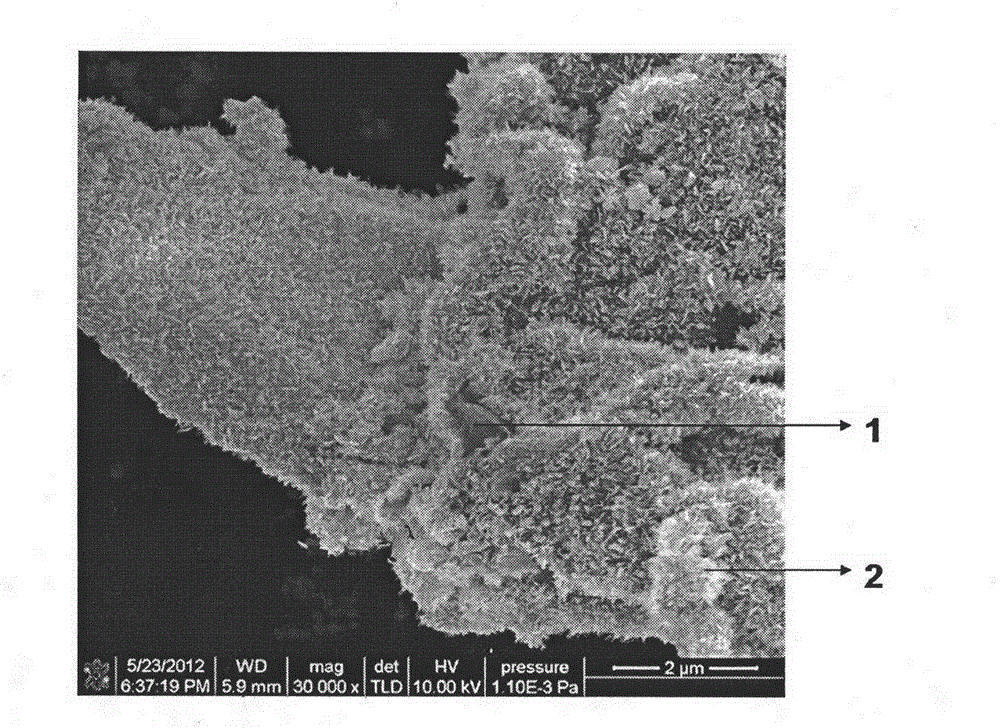

Image

Examples

Embodiment 1

[0021] A kind of preparation method of carbon material loaded tin dioxide nano sheet composite material, its specific steps are as follows:

[0022] (1) mixing and stirring

[0023] With carbon material (graphene) and tin dichloride dihydrate and sodium citrate dihydrate as raw materials, water as solvent, according to the quality (g) of graphene: the quality (g) of tin dichloride dihydrate: dihydrate The mass (g) of sodium citrate: the ratio of the volume (ml) of deionized water is the ratio of 1: 9: 29.4: 200, in container, add graphene, tin dichloride dihydrate, sodium citrate dihydrate and deionized water, mixed and stirred for 20 minutes to obtain a mixed solution of graphene and tin dioxide precursor.

[0024] (2) Hydrothermal reaction

[0025] After the step (1) was completed, the mixed solution obtained in the step (1) was moved to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and the hydrothermal reaction was carried out for 16 hours at a temperature...

Embodiment 2

[0029] A kind of preparation method of carbon material loaded tin dioxide nano sheet composite material, with embodiment 1, wherein:

[0030] In the (1) step, carbon material (carbon nanotube) and tin dichloride dihydrate and sodium citrate dihydrate are raw materials, and water is solvent, by the quality (g) of carbon nanotube: tin dichloride dihydrate The mass (g): the mass (g) of sodium citrate dihydrate: the ratio of the volume (ml) of deionized water is the ratio of 1: 1: 0.1: 50, and the mixing and stirring time in the container is 2 minutes.

[0031] In the 2nd step, hydrothermal reaction temperature is 140 ℃, and hydrothermal reaction time is 36 hours, and the mass (g) of precipitation: the volume ratio (ml) of deionized water is 1: 40, repeats like this 12 times.

[0032] In step (3), the drying temperature is 40° C., and the drying time is 96 hours.

Embodiment 3

[0034] A kind of preparation method of carbon material loaded tin dioxide nano sheet composite material, with embodiment 1, wherein:

[0035] In (1) step, carbon material (graphite) and tin dichloride dihydrate and sodium citrate dihydrate are raw materials, and water is solvent, by the quality (g) of graphite: the quality of tin dichloride dihydrate (g ): the mass (g) of sodium citrate dihydrate: the ratio of the volume (ml) of deionized water is the ratio of 1: 18: 50: 500, and the mixing and stirring time in the container is 60 minutes.

[0036] In the 2nd step, the hydrothermal reaction temperature is 250 ℃, and the hydrothermal reaction time is 2 hours, the mass (g) of precipitation: the volume ratio (ml) of deionized water is 1: 200, repeats like this 3 times.

[0037] In step (3), the drying temperature is 160° C., and the drying time is 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com