Intaglio press based on color management operation system

A gravure printing machine and operating system technology, which is applied to gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve the problems of reduced qualified yield, high labor intensity, and increased printing costs, and achieve high yield and simplified printing. Labor intensity, the effect of reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

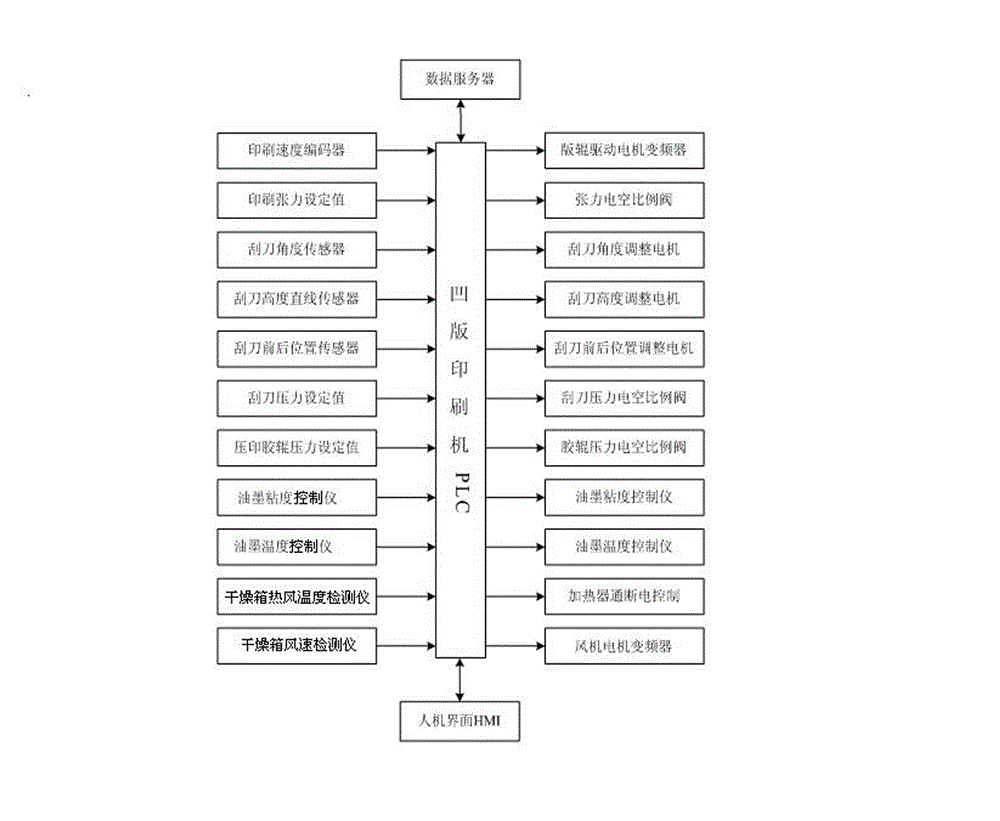

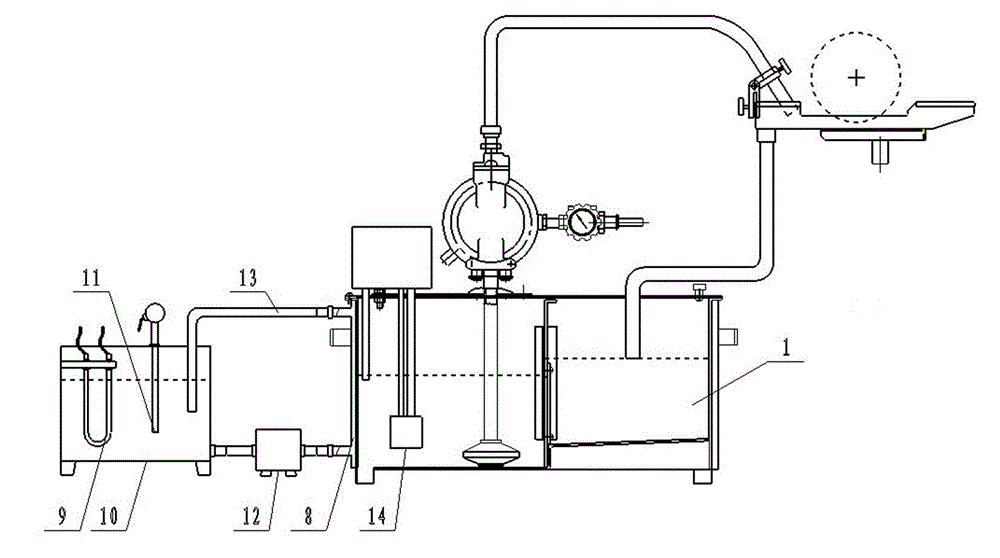

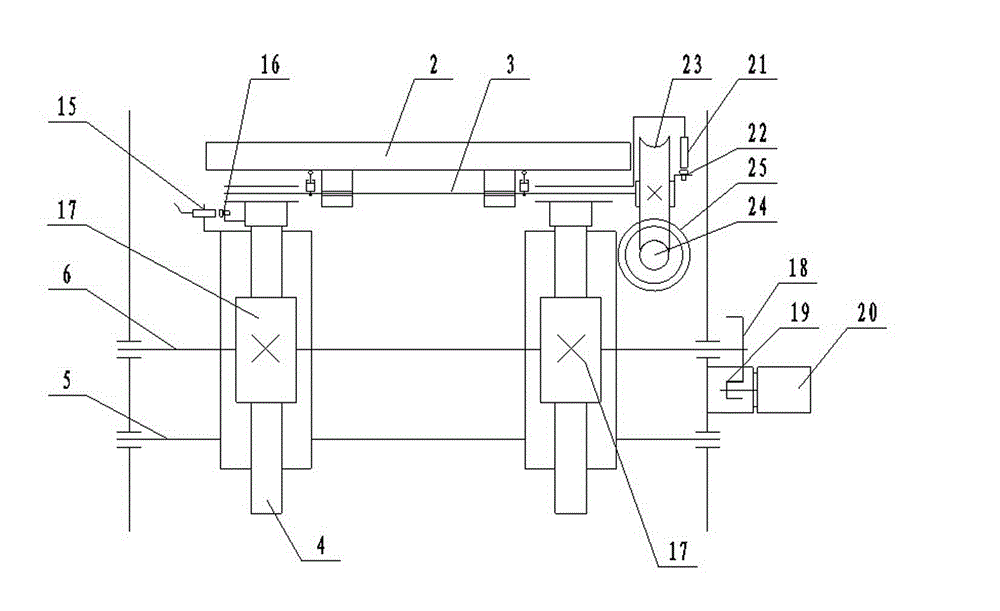

[0019] A gravure printing machine based on a color management operating system, including an ink tank 1 and an automatic ink filling device, including a scraper 2, a scraper shaft 3, a scraper support shaft 4, a scraper lower shaft 5, a scraper upper shaft 6, and a scraper booster cylinder 7 Scraper mechanism, scraper height adjustment mechanism, scraper angle adjustment mechanism, scraper front and rear position adjustment mechanism, also includes drying oven and heating controller, fan drive motor, plate roller and plate roller drive motor, embossing rubber roller and rubber roller booster cylinder , swing roller and swing roller cylinder, such as figure 1 As shown, the printing machine also includes an electrical control system. The electrical control system is composed of a PLC system, a man-machine interface and a data server. The color management data set is stored in the data server through the PLC system of the printing machine, and the PLC system can read Get the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com