Method for automatically distributing inspection and analysis steel samples

A technology for automatic distribution, testing and testing, applied in the fields of instruments, data processing applications, computing, etc., can solve the problems of inability to realize the automation of testing and testing processes, failure to form automatic distribution of testing and testing samples, inconsistent standards, etc., to simplify labor intensity, The effect of low information error rate and high system real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

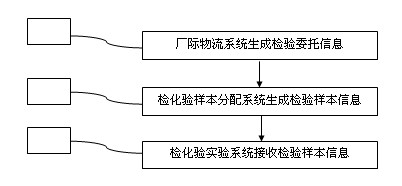

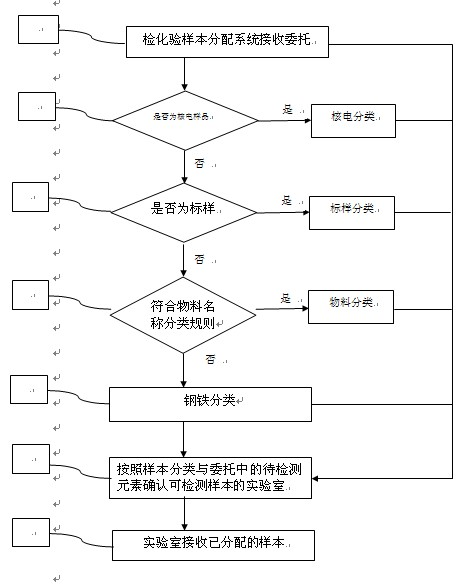

[0023] Embodiment: the inspection sample distribution system in the present invention is by constructing the iron and steel inspection information system ( Figure 5 shown) to achieve. The steel inspection and testing information system includes the interfactory logistics system, the inspection and testing sample distribution system, and the inspection and testing experiment system. The interfactory logistics system mainly provides sample basic information and inspection commission information for the inspection and testing sample distribution system, and the inspection and testing sample distribution system can At the same time, it provides inspection project information for multiple inspection and testing experiment systems. The system uses TCP / IP protocol to link the interfactory logistics system, inspection and testing sample distribution system and inspection and testing experiment system.

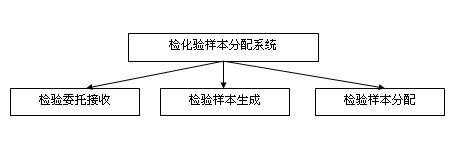

[0024] figure 1 , figure 2 , image 3 , Figure 4 As shown, the test sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com