Connecting rod press machine with swinging guide rod

A technology of swinging guide rod and press, applied in the field of mechanical press, can solve the problems of high working speed of the slider, low working efficiency and high cost, and achieve a simple and compact structure, good low-speed forging and rapid return characteristics, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

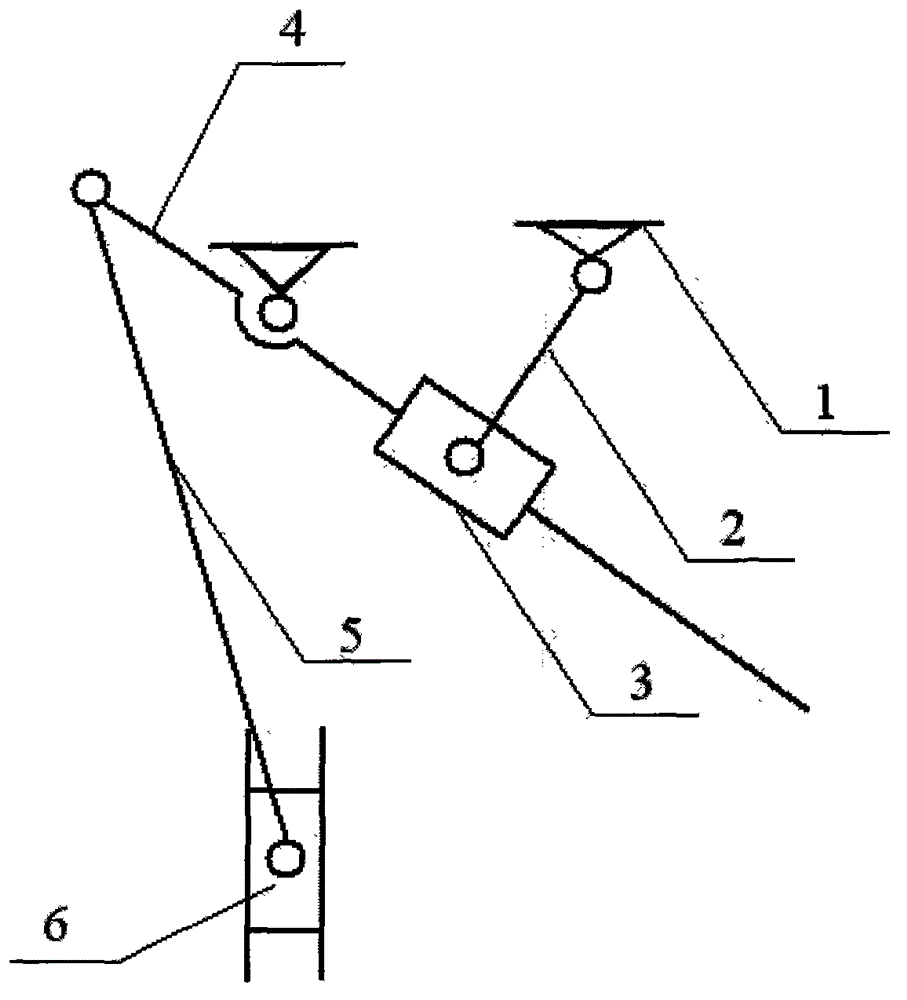

[0007] Such as figure 1 The specific embodiment of the invention shown is a connecting rod press with a swing guide. The hammer connecting rod 5, the impact hammer 6, and the crank 2 are respectively connected to the frame 1 and the slider 3 through the rotating pair; the slider 3 is connected to the swing rod 4 through the moving pair; the swing rod 4 is connected to the frame 1 through the rotating pair It is connected with the hammer connecting rod 5; the end of the hammer connecting rod 5 is connected with the hammer 6 through a rotating pair, and the hammer 6 is in the fixed guide rail.

[0008] When working, the crank 2 rotates under the drive of an ordinary fixed-speed motor to provide kinetic energy for the press. Under the action of the rotation of the crank 2, the slider 3 moves along the swing rod 4, and the swing rod 4 swings on a fixed axis. Driven by the pendulum 4, the hammer connecting rod 5 makes a complex planar movement. During this process, the hammer 6 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com