Chain supporting wheel and lower part bend wheel of shallow slot separator

A sorting machine and reversing wheel technology, applied in the direction of conveyors, solid separation, wet separation, etc., can solve the problems of broken chains, high requirements for replacement and installation, and difficult maintenance, so as to reduce off-chains, low processing costs, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

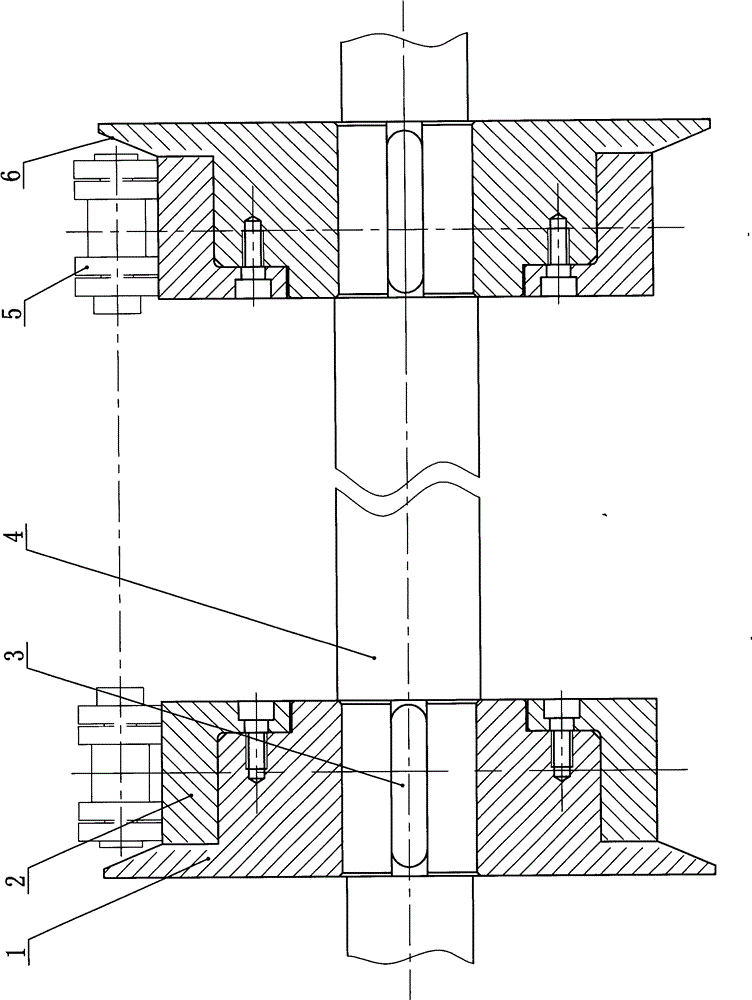

[0008] As shown in the accompanying drawings, the wheel hub 1 is T-shaped, the hub sleeve 2 is a groove type matched with the wheel hub 1 , and a slope 6 is provided on the inner side of the outer edge of the wheel hub 1 . The two hubs 1 are oppositely installed on the two ends of the shaft 4 through the key 3, and the hub sleeve 2 is fastened on the hub 1 with screws. The ends of the two hubs 1 form a trapezoid, which can prevent the sprocket from running off; the inclined plane 6 on the hubs 1 can prevent the chain from falling off. The outer edge of the hub sleeve is the running surface of the chain 5. When the chain is running, it slides on the hub sleeve to drive the hub and the shaft to rotate. The replacement is convenient, the processing is convenient and the cost is low, and the accidents related to the chain can be effectively reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com