Repair of composite materials

A prepreg, viscosity technology, used in thin material processing, adhesives, textiles, etc., can solve the problem of not providing durable repair of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

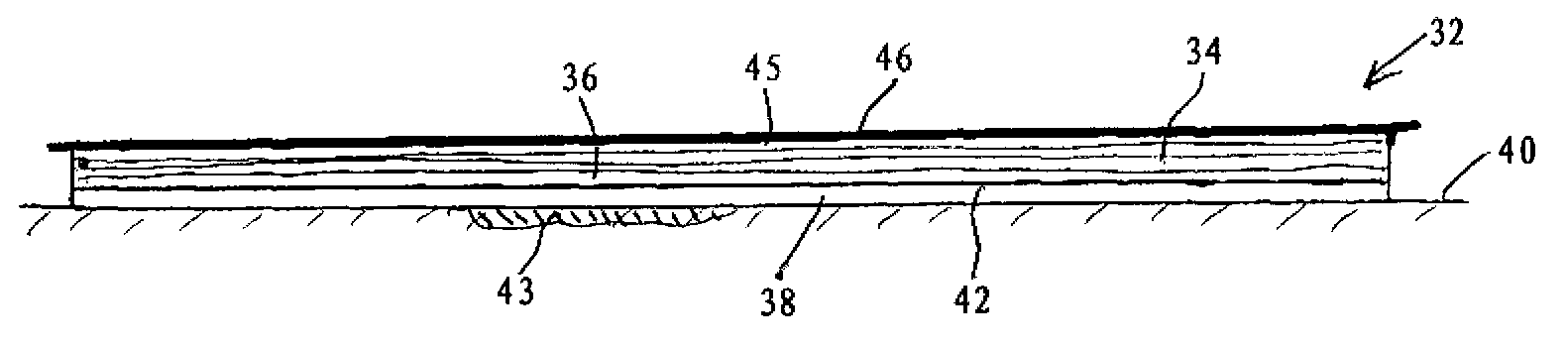

Image

Examples

Embodiment 1

[0127] From epoxy resin and unsaturated acid to form unsaturated epoxy ester 2,2-propyl-[di-1,1'-(phenyl-4,4'-{2- hydroxypropyl ether})]-bis[ethylmethacrylate]benzene-1,2-dicarboxylate to produce a prepreg resin containing 2 unsaturated methacrylic acid groups.

[0128]

[0129] The resin is manufactured as follows: In the first reaction step, 1 mole of hydroxyethyl methacrylate (HEMA) is reacted with 1 mole of phthalic anhydride at 100°C for 2 hours to produce HEMA phthalic acid ester.

[0130] Then, in a second reaction step, 2 moles of HEMA phthalate were mixed with 1 mole of bifunctional diglycidyl ether bisphenol A epoxy resin (commercially available under the trade name DER330) with a molecular weight of about 354 at 100 8 hours at a temperature of °C. This provides the unsaturated monomers of the prepreg resin.

[0131] Subsequently, a photoinitiator curing agent as a polymerization catalyst of an unsaturated monomer was added to the reaction product by dispersing...

Embodiment 2

[0142] Coating resins were made by blending varying proportions of 2HPE resin from Example 1 with Scott Bader Crystic 2-406 Pa unsaturated polyester resin, optionally using M5 silica as a thixotropic agent, to form a pasty coating resin.

[0143] Depending on sunlight conditions, the working time of the resin blend is about 0.5~3 minutes when exposed to sunlight at 20°C.

[0144] For a prepreg patch of 2400 gsm fibers impregnated with 44 wt % resin prepared according to Example 1 and coated with 400 gsm coating resin, the ease of spreading of the coating resin over the prepreg, resin sag resistance and flow was analyzed Level. The ability to apply the patch to the substrate air-free was analyzed as follows: first, the resin was applied to a prepreg patch 500 mm long and 150 mm wide, allowing the patch to float, using a slidable wet-applied resin, applied to On the ground substrate, the air bubbles are squeezed to the end of the prepreg using extrusion technology.

[0145] ...

Embodiment 3

[0151] In order to test the adhesion of prepregs according to embodiments of the present invention to substrates by using coating resins, fabricated in 100s -1 It has a viscosity of 155Pa.s when measured at 20°C at a shear rate of 1s and -1 A coating resin consisting of 60 parts of 2HPE and 40 parts of Scott Bader Crystic 2-406 Pa unsaturated polyester resin having a viscosity of 305 Pa.s when measured at 20°C at a shear rate of .

[0152] Double lap shear specimens were prepared by grinding polyester and epoxy laminate substrates. Center cut the center of the board down, then butt the board halves together. A 40 mm wide prepreg tape made from the 3 x 600 gsm prepreg of Example 1 was coated with the above coating resin. The prepreg with coating resin is pressed onto the substrate. The rolling direction of the prepreg is parallel to the cutting direction, providing + / - 45° of fiber relative to the gap between the substrate halves.

[0153] Then, a position 475mm below the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com