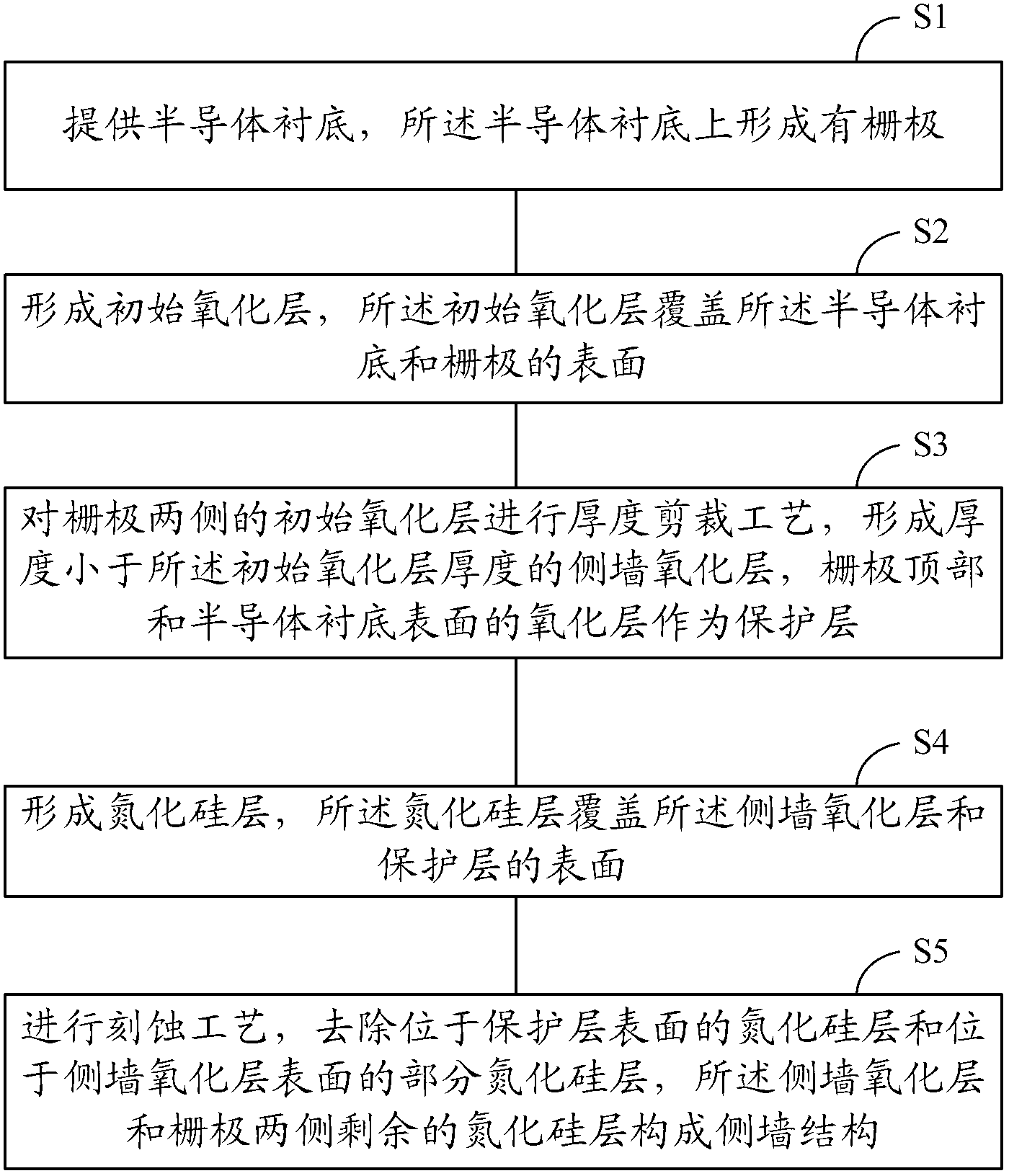

Side wall structure construction method

A technology of a sidewall structure and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of silicon damage, large stress, and impact on device performance of semiconductor substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

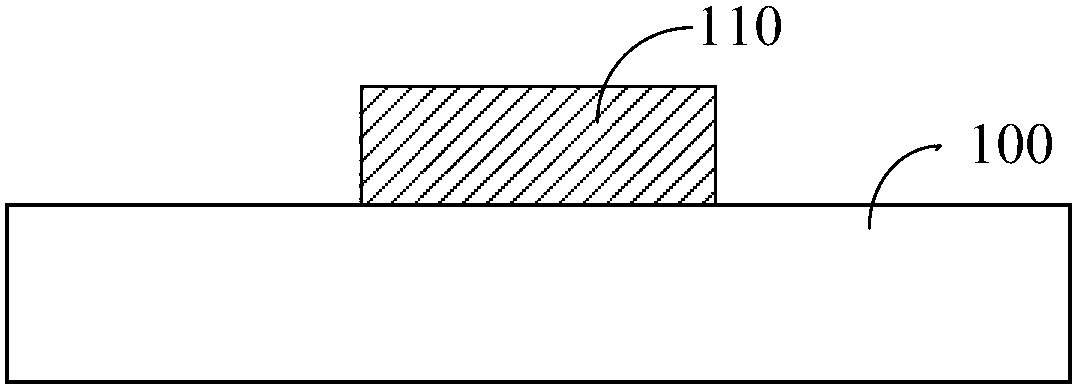

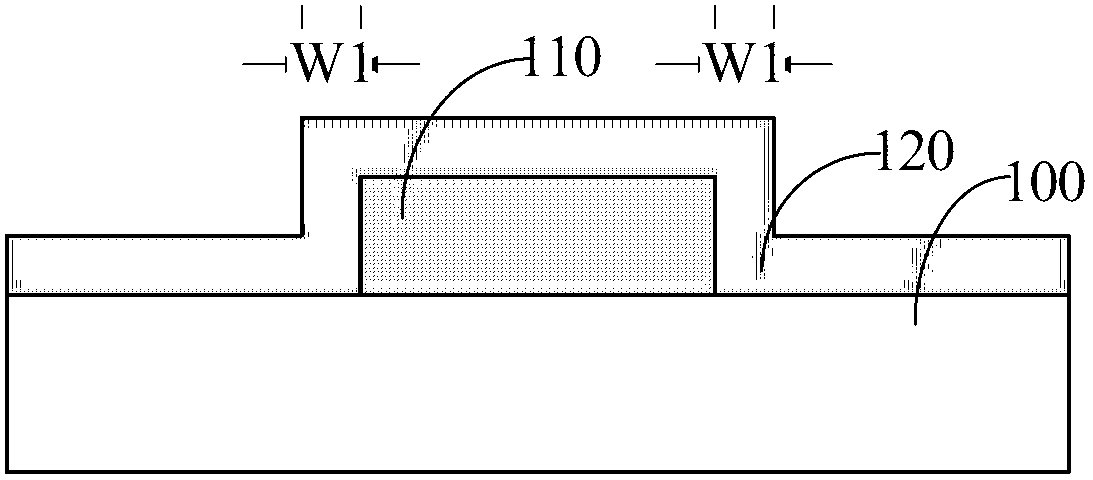

[0027] For processes with a feature size of 65 nanometers and above, the thickness of the sidewall structure is relatively large, usually greater than 100 angstroms, and the manufacturing process of the sidewall structure is relatively easy. However, as the feature size of the device is reduced, the inventor found that it is impossible to form a sidewall structure with a smaller thickness using the existing technology. If a single silicon oxide layer is used to make the sidewall structure, the process of etching the silicon oxide layer to form the sidewall structure will cause silicon damage to the semiconductor substrate (Siloss). If a single silicon nitride layer is used to make the sidewall structure, Then the silicon nitride layer causes greater stress on the device, thereby affecting the performance of the device. Therefore, the inventor considers using a silicon oxide layer and a silicon nitride layer to make the sidewall structure. In order to ensure that the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com