Shifting register unit, shifting register, display device and driving method

A technology for shift registers and storage capacitors, which is applied in the field of display devices, shift registers, and shift register units, and can solve the problems of the third thin film transistor M3 affecting the service life and the display panel display lines not working properly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

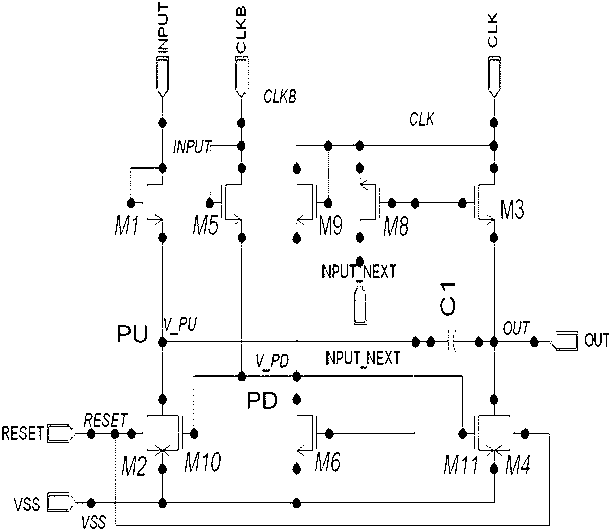

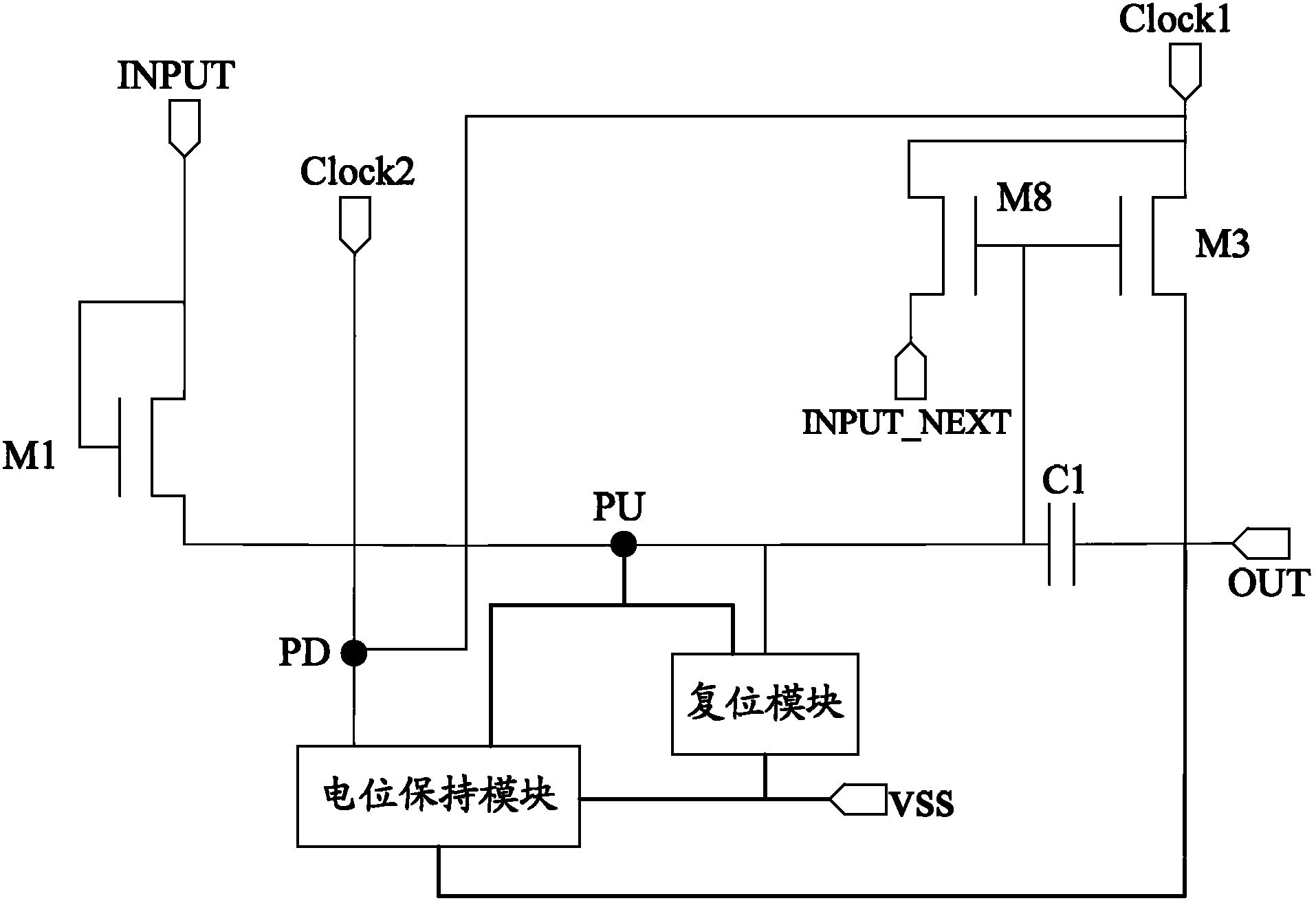

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a shift register unit, including:

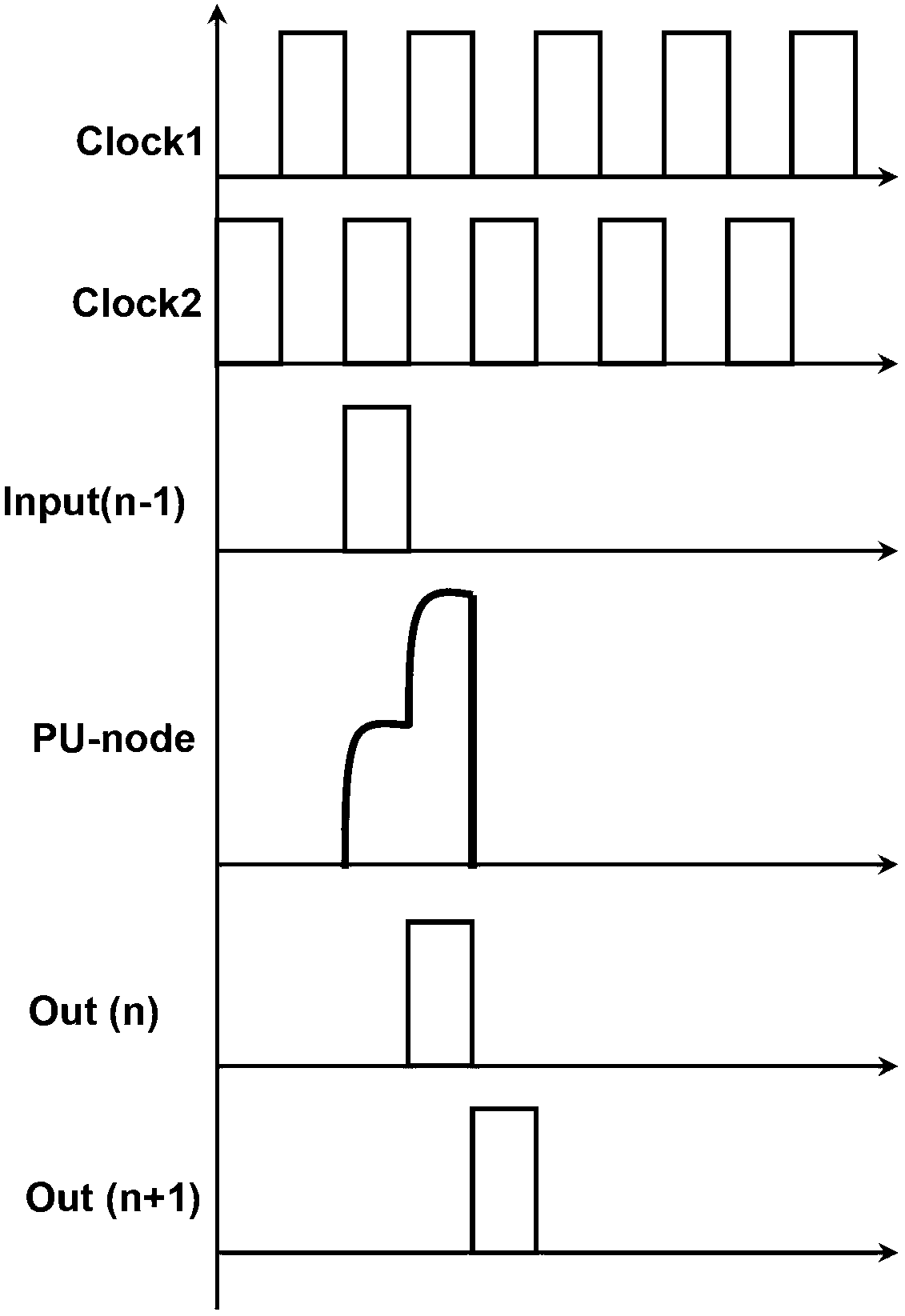

[0038] The first thin film transistor M1 is used to charge the pull-up node PU and the storage capacitor C1 when the input signal INPUT is at a high level; wherein, the input signal INPUT of this stage is input from the INPUT_NEXT terminal of the previous stage; preferably , when the eighth thin film transistor M8 is turned on, the first clock signal Clock1 is output to the INPUT_NEXT terminal through the eighth thin film transistor M8;

[0039] A reset module, configured to discharge the pull-up node PU and the storage capacitor C1 according to the control of the reset signal;

[0040] The third thin film transistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com