Single-layer ITO (indium tin oxide) wiring structure

A wiring structure and single-layer technology, applied in the field of single-layer ITO wiring structure, can solve the problems of unstable touch detection, inability to quickly distinguish, large power supply noise interference, etc., to ensure capacitance and signal strength, The effect of stable touch detection and simple wiring structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

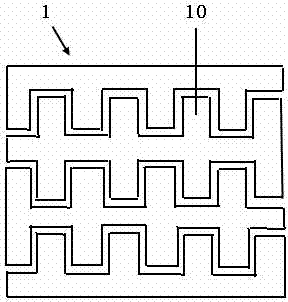

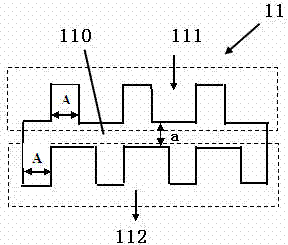

[0013] Please refer to figure 1 As shown, the present invention relates to a single-layer ITO wiring structure. The single-layer ITO 1 is provided with a plurality of electrode blocks 10 to form several vertical rows and columns, that is, each vertical row or column is composed of a plurality of contacts. The control electrode block 10 is composed. The shape of the electrode block 10 is enclosed by upper and lower rows of symmetrical rectangular waves with equal amplitude and opposite directions, wherein the upper row of rectangular waves is 101, the lower row of rectangular waves is 102, and the upper row of rectangular waves A gap 100 is formed between the wave 101 and the lower row of rectangular waves 102, the length of which is denoted by "a". Viewed from one direction, the shape of the electrode block 10 is roughly composed of the word "earth",...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com