Fruit hardness detection method and special electronic fruit hardness tester

A detection method and technology of hardness tester, applied in the direction of testing the hardness of materials, etc., can solve problems such as difficulties, disputes, and great differences, and achieve the effect of ensuring accuracy and consistency, ensuring accuracy, and being easy to calibrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

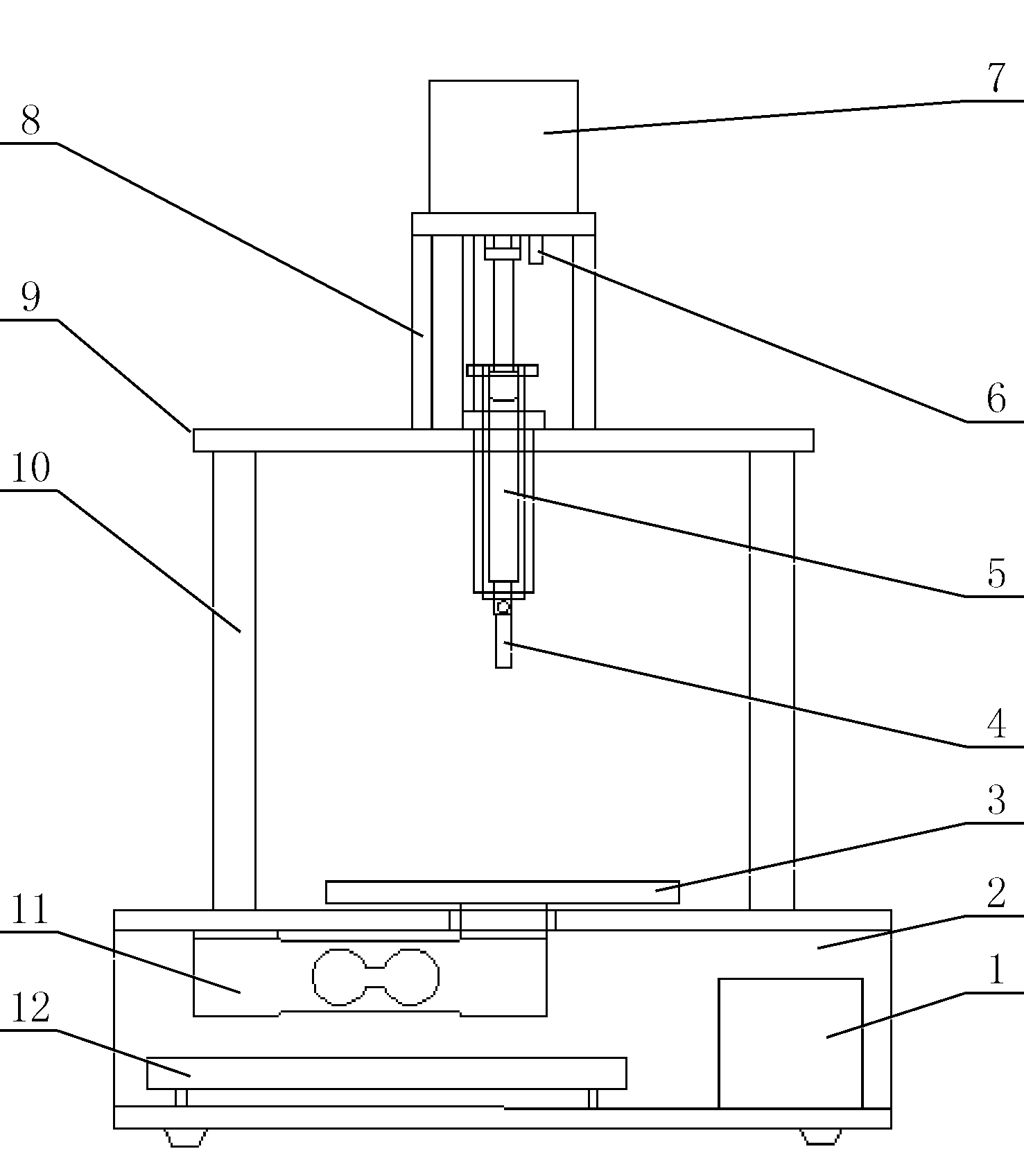

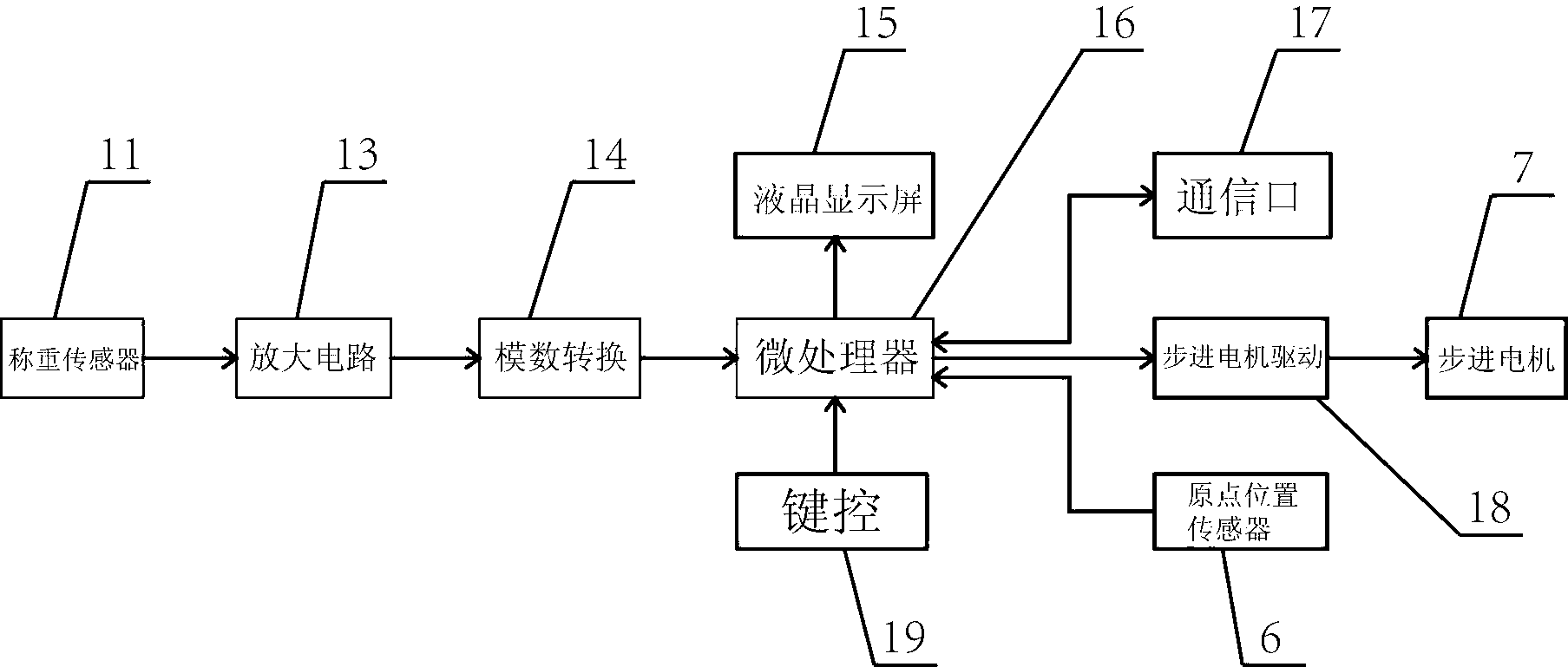

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] The measuring method of the present invention is as follows.

[0029] After the instrument is started, it will be automatically cleared for the first time. At this time, the weights for calibration are put on, and the weight value is displayed on the liquid crystal display 15, and the load cell 11 is calibrated.

[0030] During measurement, firstly, the fruit to be checked is placed on the tray 3 connected to the load cell 11 , and the fruit to be checked is located directly below the measuring pressure head 4 .

[0031] Then control the load cell 11 to clear for the second time, control the stepper motor 7 to run forward, and drive the measuring pressure head 4 to move downward at a constant speed. When the measuring indenter 4 touches the fruit, the load cell 11 senses the incremental signal and transmits the signal to the microproces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com