Disconnected electrical contact fusion welding force detection device and method

A testing device and testing method technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of measurement accuracy, high cost, easy spring shaking, etc., to achieve high sensitivity, high stability, Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

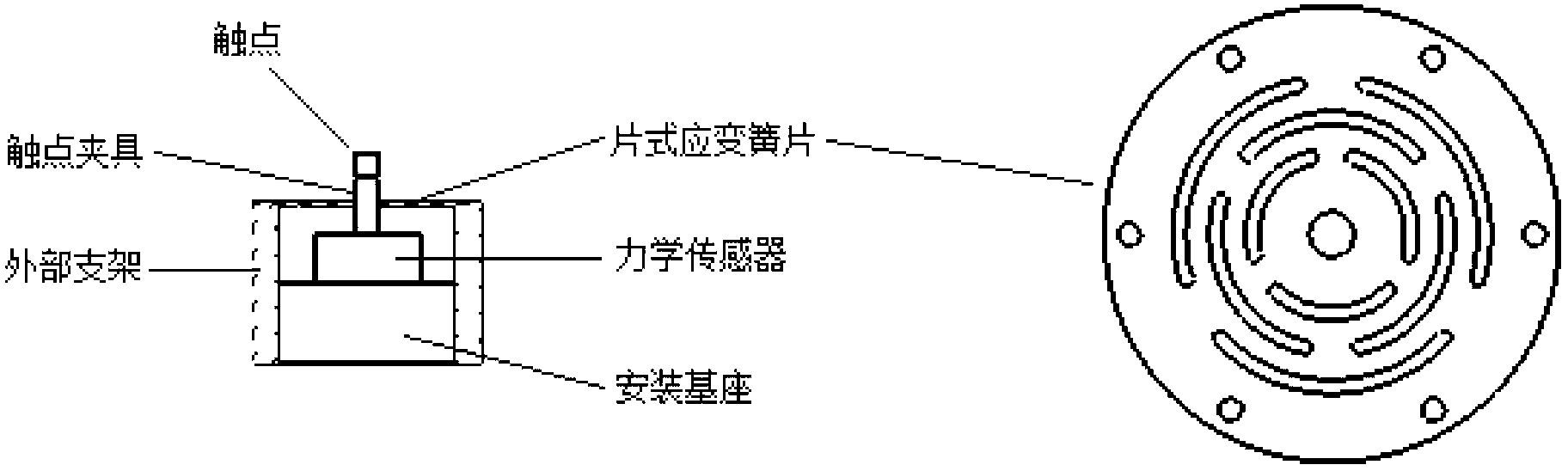

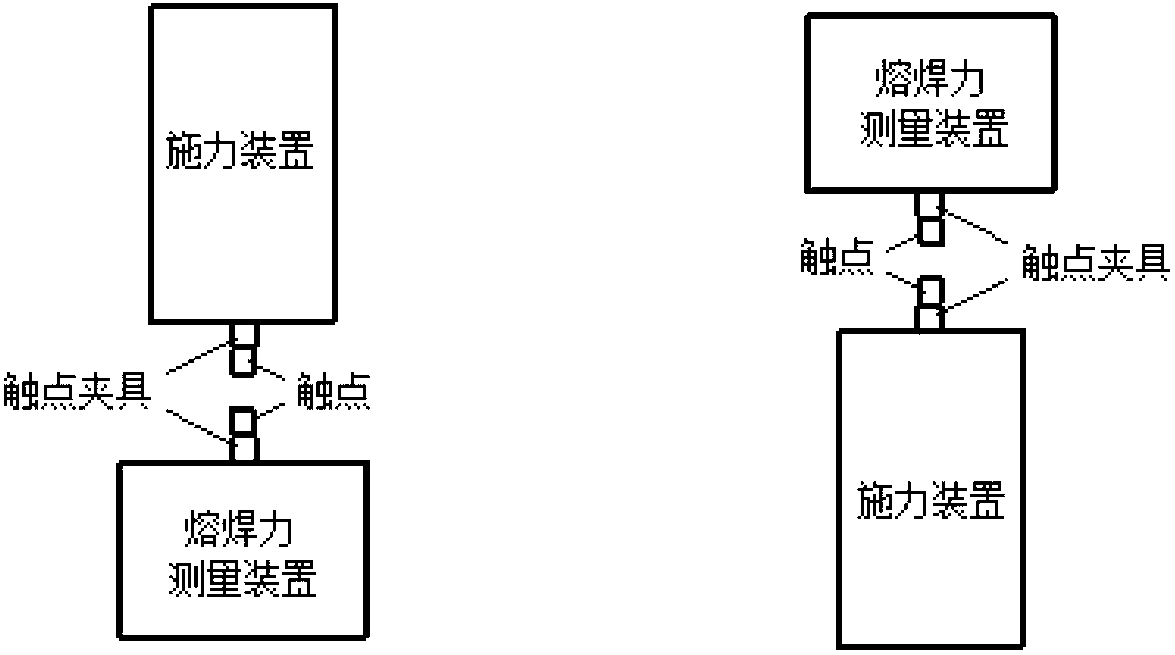

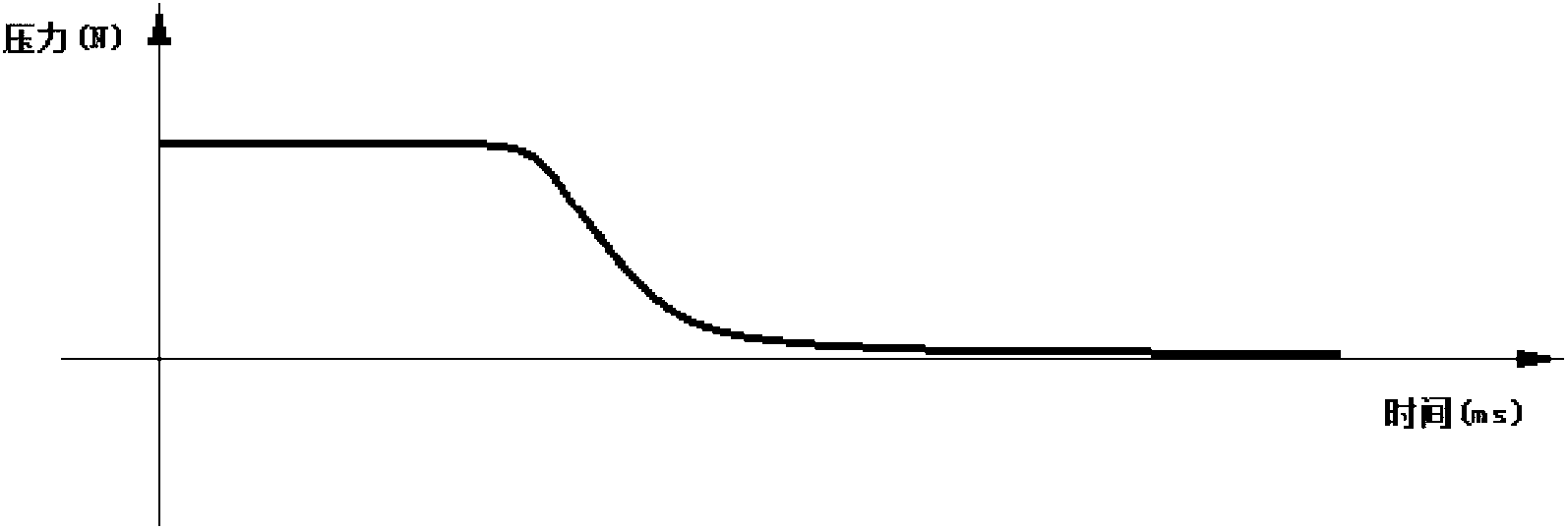

[0014] Embodiment 1 The sensor uses a 500cN force sensor, and a vibrator is used as the driving source. The maximum force of the vibrator is 10N, and the displacement range is 8mm. It is driven by a square wave with a duty cycle of 50%. The clamp is fixed at the end of the central shaft of the exciter, and the clamping contact is used as a moving contact. The static contacts are clamped using a welding force tester as described in the Summary of the Invention. The outer diameter of the reed and bracket of this device is 105mm, and the height of the bracket is 90mm. The output signal of the force sensor of the fusion welding force test device is connected to the peak value holder and the computer data acquisition system, and the peak value holder is reset before each breaking. After breaking, the computer reads the negative peak signal through the data acquisition system to calculate the fusion welding force. Weld force measurement range: +245cN to -245cN.

[0015] The contac...

Embodiment 2

[0017] Embodiment 2 A 2000g mechanical sensor is used as the sensor. A cylinder with a stroke of 15mm is used as the driving source, and a two-position five-way solenoid valve is used. The voltage of the solenoid valve coil is 12V, and compressed air is supplied. The contact fixture is fixed at the end of the cylinder, and the contact is clamped on the fixture as a moving contact. The contacts are clamped by means as previously described and act as stationary contacts. Adjust the relative position between the cylinder and the welding force testing device to obtain the stroke and closing pressure required for the experiment. When the solenoid valve is supplied with 12V voltage, the cylinder stretches out, the moving contact clicks on the static contact, and the contacts are closed; after the solenoid valve is powered off, the cylinder retracts, and the contacts are broken.

[0018] The dynamic and static contacts of the experimental materials are AgSnO2 / Cu composite contacts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com