Glass meter reading system based on machine vision

A technology of glass gauges and reading systems, applied in instruments, measuring devices, liquid/fluid solid measurements, etc., which can solve problems such as eye fatigue and easy reading of wrong data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

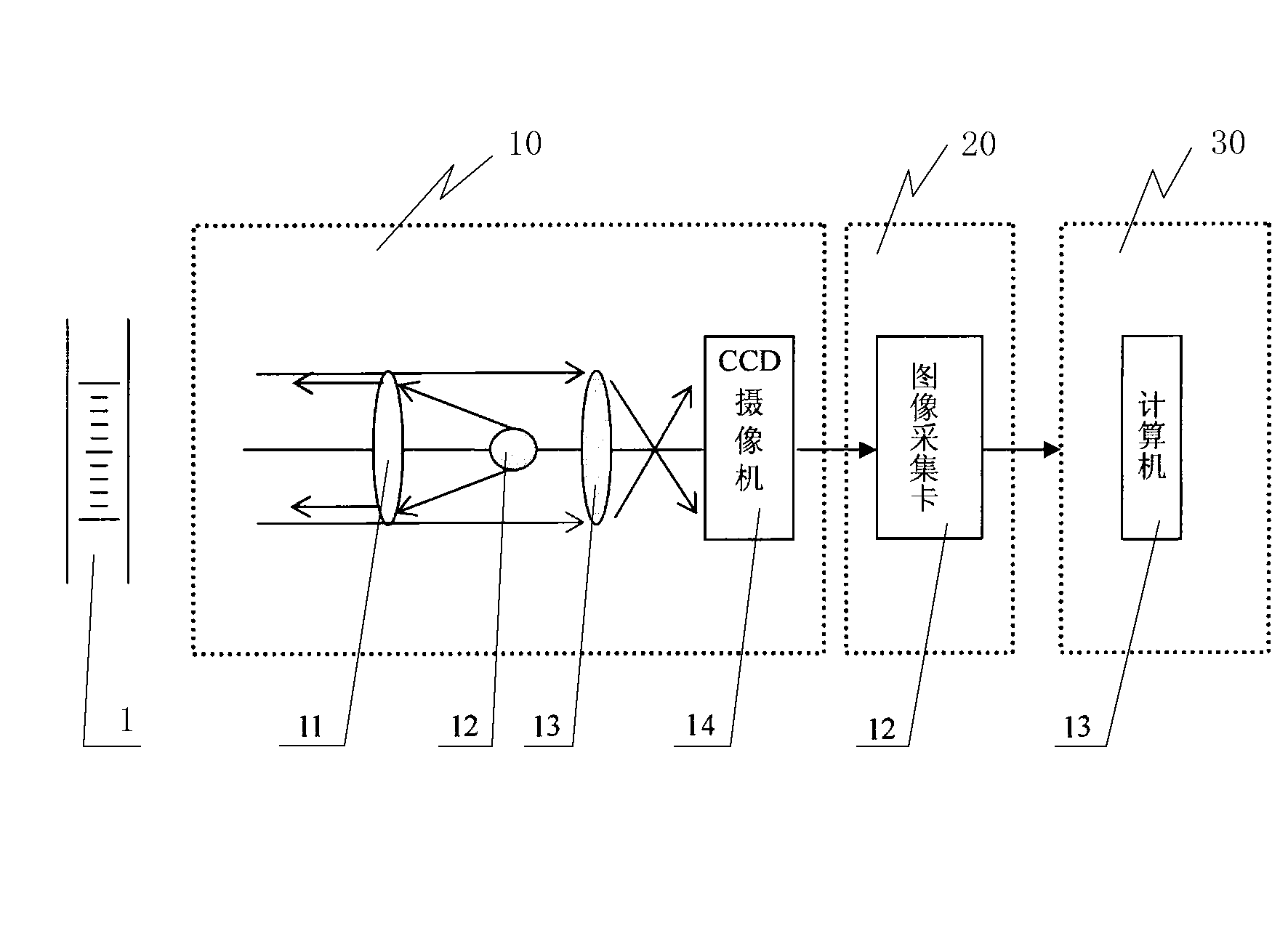

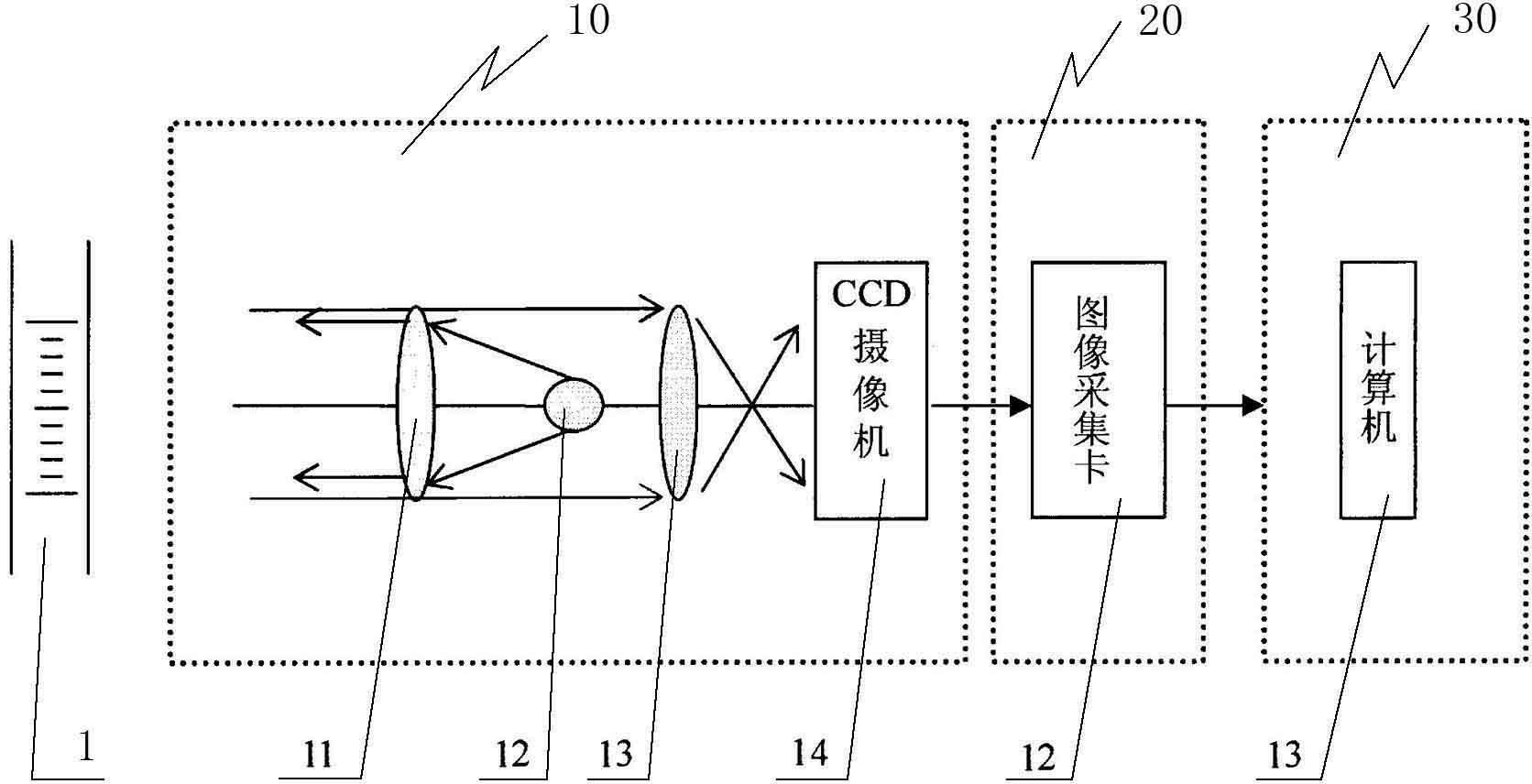

[0009] Such as figure 1 As shown, a glass measuring instrument reading system based on machine vision includes an imaging system 10, an acquisition system 20 and a processing system 30 connected in sequence; wherein the imaging system 10 is provided with a light source 12 between a condenser lens 11 and an objective lens 13, Condenser 11, light source 12 and objective lens 13 are on the same optical axis simultaneously, and the other side of objective lens 13 is provided with CCD camera 14; Described acquisition system 20 is image acquisition card 21; Described processing system is computer 31.

[0010] Its working principle is: the imaging system light source 12 generates parallel light after being concentrated by the condenser lens 11, and the parallel light is projected onto the measured device 1, and the image of the measured device is imaged to the photosensitive surface of the camera 14 through the imaging system objective lens 13, and the acquisition system The graphics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com