Device for eliminating optical interference effect in wave plate processing process

A process and optical interference technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inaccurate grinding thickness of wave plates, and achieve the effect of eliminating interference effects, strong feasibility and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

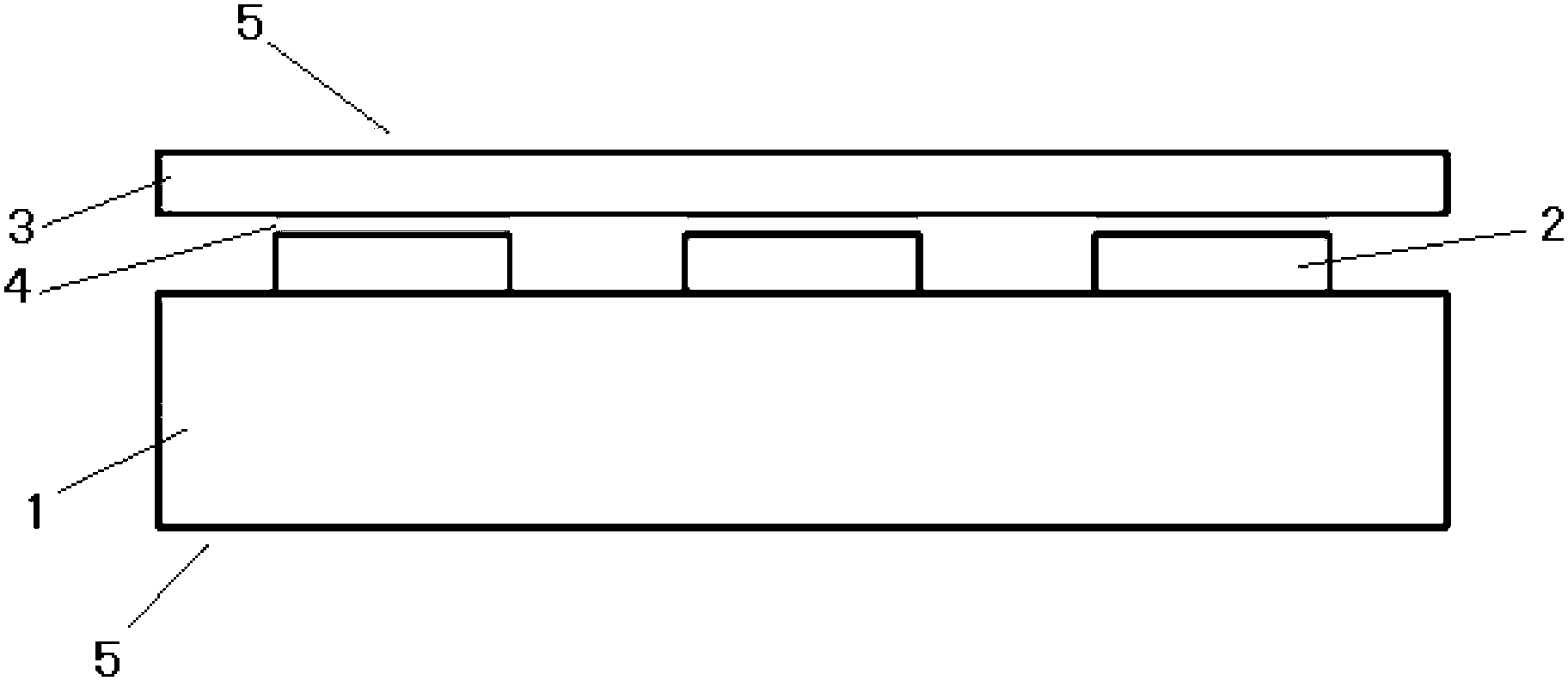

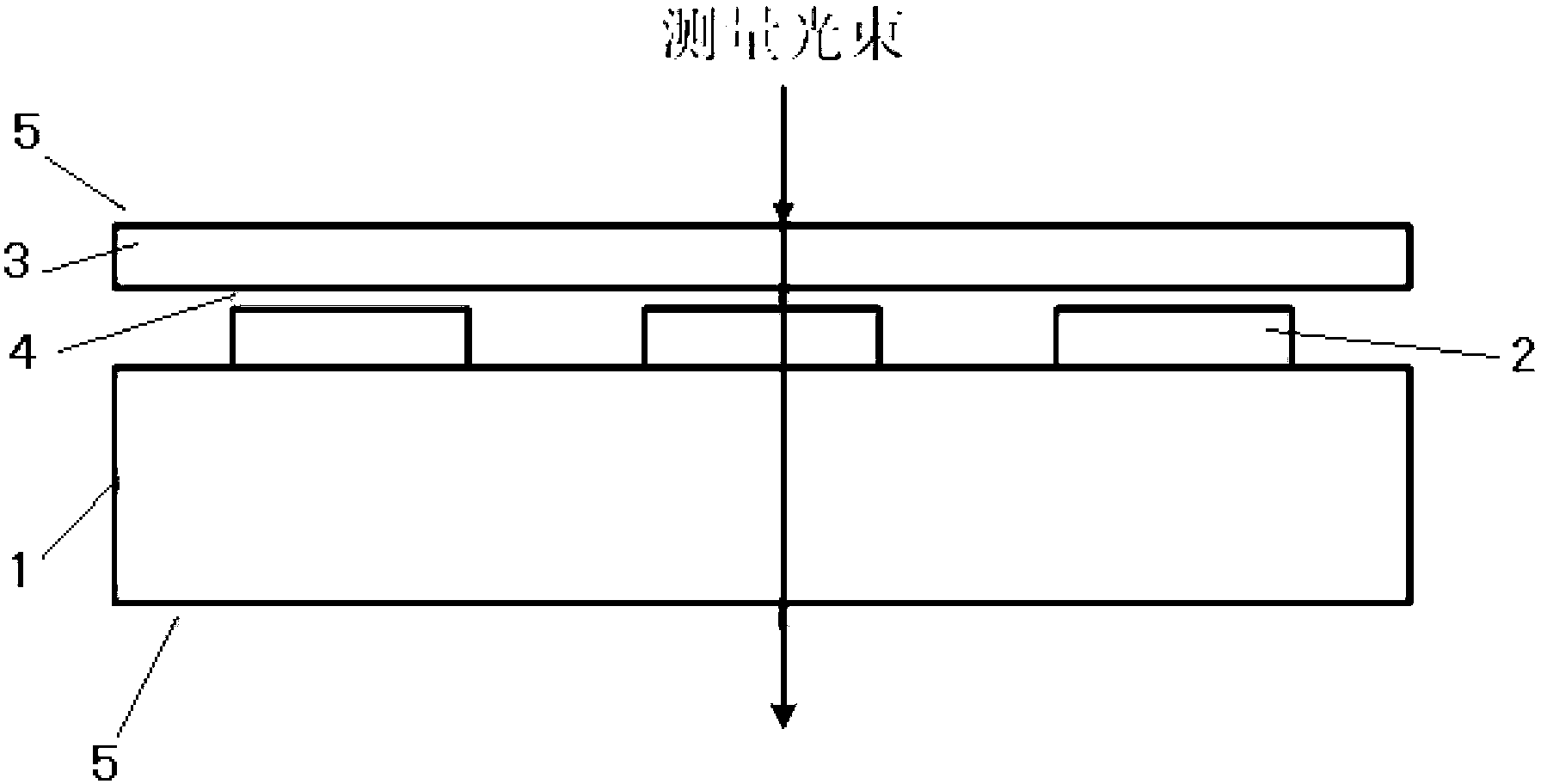

[0016] Such as figure 1 As shown, the device for eliminating the optical interference effect of the present invention comprises a photoresist disc 1, more than one wave plate 2 to be ground and a flat glass 3; , the plate glass 3 is arranged on the upper surface of the wave plate 2, and the upper surface of each wave plate 2 and the lower surface of the plate glass 3 are in contact with a matching layer 4 made of a refractive index matching liquid. The function of the matching layer 4 is to make each The wave plate 2 is in close contact with the flat glass 3 without air, and an antireflection film 5 is provided on the upper surface of the flat glass 3 and the lower surface of the photoresist disc 1 respectively.

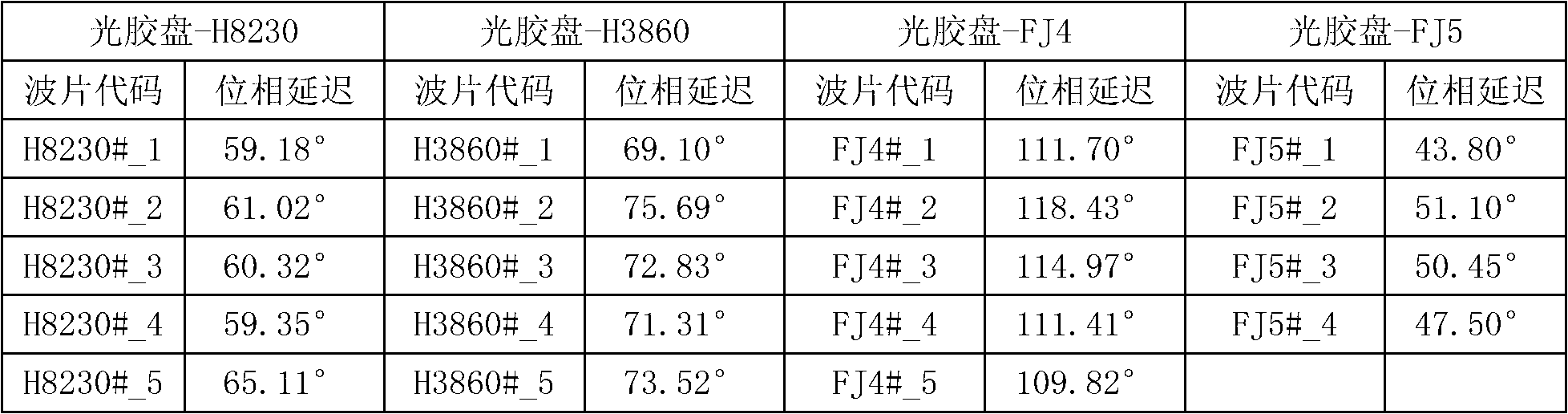

[0017] In the above-mentioned embodiment, the refractive index of the photoresist disc 1 is usually 1.5-1.53, which can be made of BK7 gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com