Multi-functional heating furnace

A heating stove and multi-functional technology, which can be applied to household stoves/stoves, stoves/stoves with hot water devices, and household heating, etc., can solve the problems of waste of resources, increased use costs, low thermal efficiency, etc., and achieve economical use. volume, improve the utilization rate, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

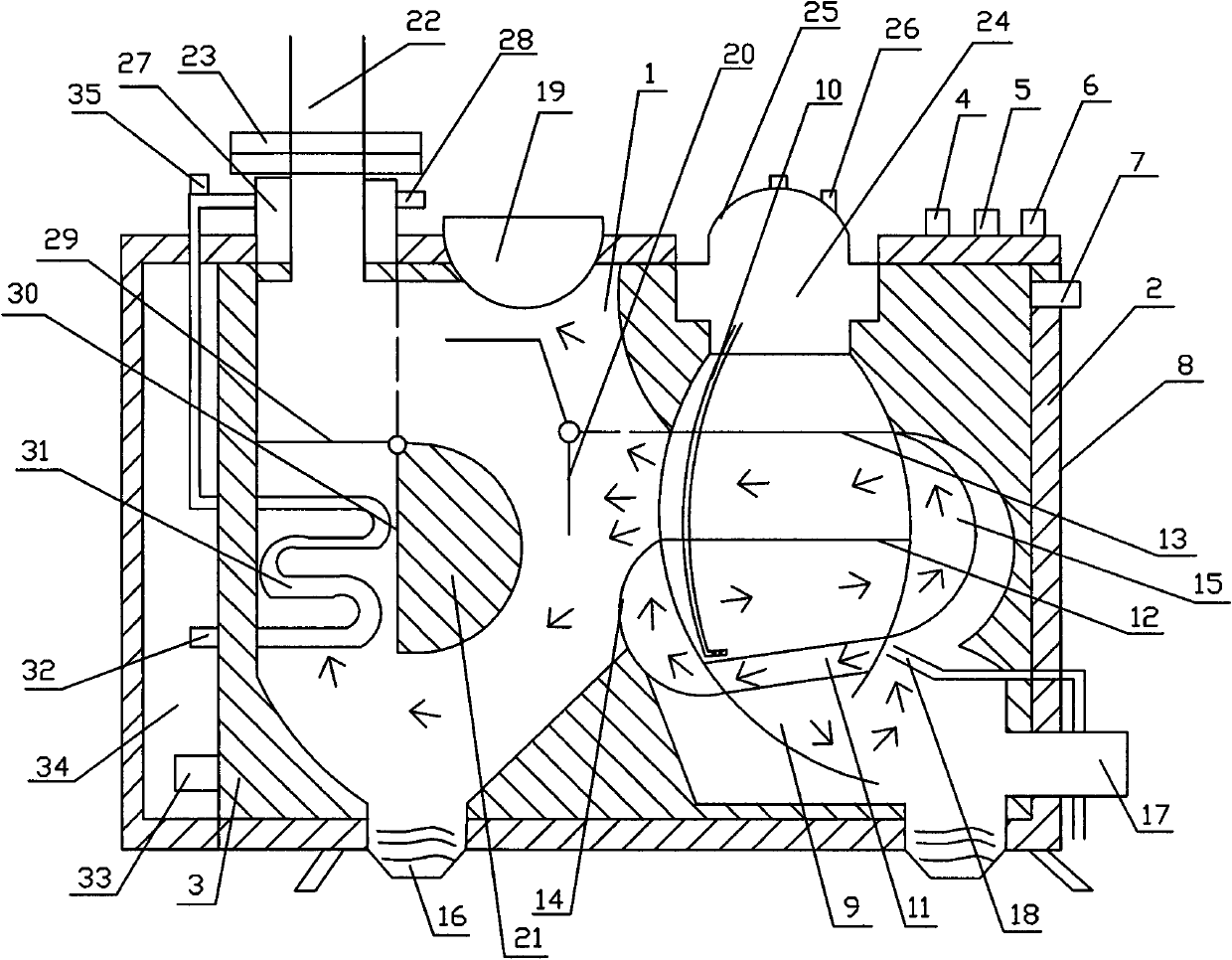

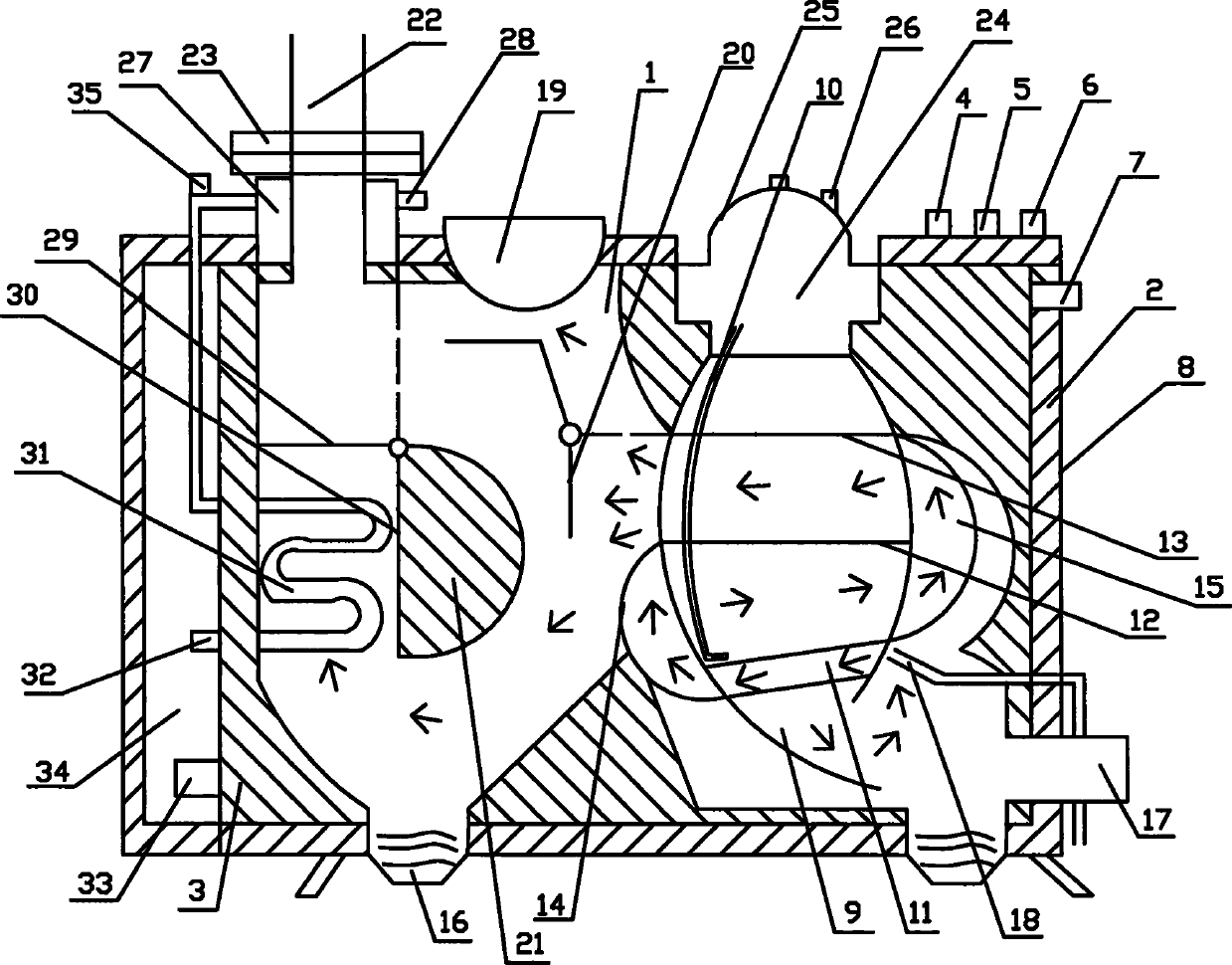

[0018] A multifunctional heating furnace, comprising a heating furnace main body 1, a coal filling port, a heating water outlet 7, a heating water inlet 33, a heating water jacket 3, a smoke outlet 22 and a slag removal port 17, and the coal charging port is arranged on the heating furnace main body 1, an unclosed furnace 9 is connected below the coal inlet, a radiator 23 is provided on the smoke outlet 22, and a cast iron tubular grate smoke guide pipe 11 is arranged in the furnace 9, and the furnace is an independent furnace 9. The outer periphery and the bottom of the heating furnace main body 1 are provided with an insulating layer 2 and a shell 8, a baffle plate 12 and a baffle plate 2 13 are arranged on the outer surface of the furnace liner 9, and the smoke outlet of the furnace liner 9 leads to the fire grate smoke guide pipe 11. The flue gas inlet and the flue gas outlet of the grate smoke guide pipe 11 are connected with an arc-shaped plate 14, which is respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com